[ad_1]

On September 14th, South Texas SpaceX technicians raised the third and last dome of the Starship Mk1 tank and began to fix it above the prototype steel tank section, this time using a new method of integration.

This progress comes just two weeks before CEO Elon Musk presents a detailed update of the latest design iteration of Starship. Musk is hopeful that the Starship Mk1 will be nearing completion and ready for its maiden flight on September 28th, a milestone that could come as early as October 13, according to Starship documents filed with the FCC.

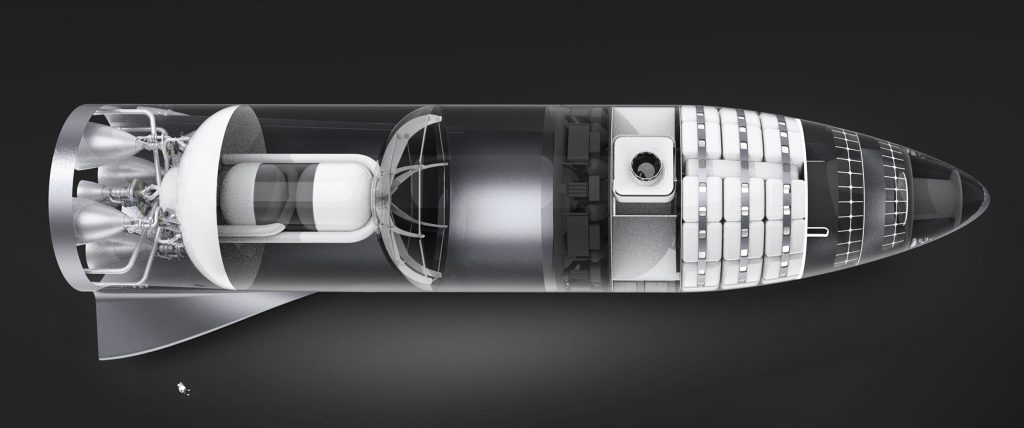

This last installation is probably the last (or almost) ring to be stacked on the Mk1 spacecraft, paving the way for the possible attachment of the cone nose of the spacecraft and the development of its many internal subsystems and aerodynamic control surfaces. This particular milestone involved the fixing of the third and final bulkhead of the Starship tank – in this case, the upper dome of the prototype's liquid oxygen tank. Excluding equipment that could possibly be installed on the dome itself, this means that the tanks and engines part of the Starship Mk1 has been essentially "filled".

As previously estimated by the author, this particular tank dome installation – the fifth performed by the Spacek Mk1 and Mk2 Starship teams – was uniquely performed. All previous installations have seen SpaceX technicians lower the domes – made in addition to a vertical weld for more flexibility – inside the cylindrical tank section of the spacecraft. The steel domes are then carefully spot welded on the side of the tank – while being supported by a large crane – before the technicians can perform a seamless ring weld all the way around.

This time, SpaceX welded the top dome of the tank to the section of its ring while the two elements were still on the ground. Once the dome was completely welded to the steel ring and a dome cap was installed to seal the top, the ring segment was dug at the top of Starhip Mk1 on September 14th. It may have been planned forever for the third and last dome of every Starship ship, but the way Chief Executive Elon Musk has already described the semi-competitive versions of SpaceX, Mk1 and Mk2, suggests that 39 it could be a new build strategy that has evolved in the last month or two.

Instead of having to adjust, fix and weld the bulkhead to the Starship spaceship tank section at 50-100 feet above the ground, with all the rigging, scaffolding and challenges associated with the demands of the ship. such a work environment, technicians have been able to do the majority of this work at ground level. This method seems to mitigate the added challenge of installing domes in the vertical ring installation process, effectively merging the two processes into a much simpler (and safer) exploit.

The fact that the Starship Mk1 tank section is now closed (with the exception of several smaller access ports) indicates that all large plumbing components were installed inside the prototype. steel. Then come for Starship Mk1 is the installation of its legs / fins / wings of landing (of which at least two have already arrived on site), its ducks and various smaller additions such as valves, thrusters, points earth connection, etc. .

Check Teslarati newsletters for quick updates, on-the-ground perspectives and a unique insight into SpaceX rocket launch and recovery processes.

[ad_2]

Source link