[ad_1]

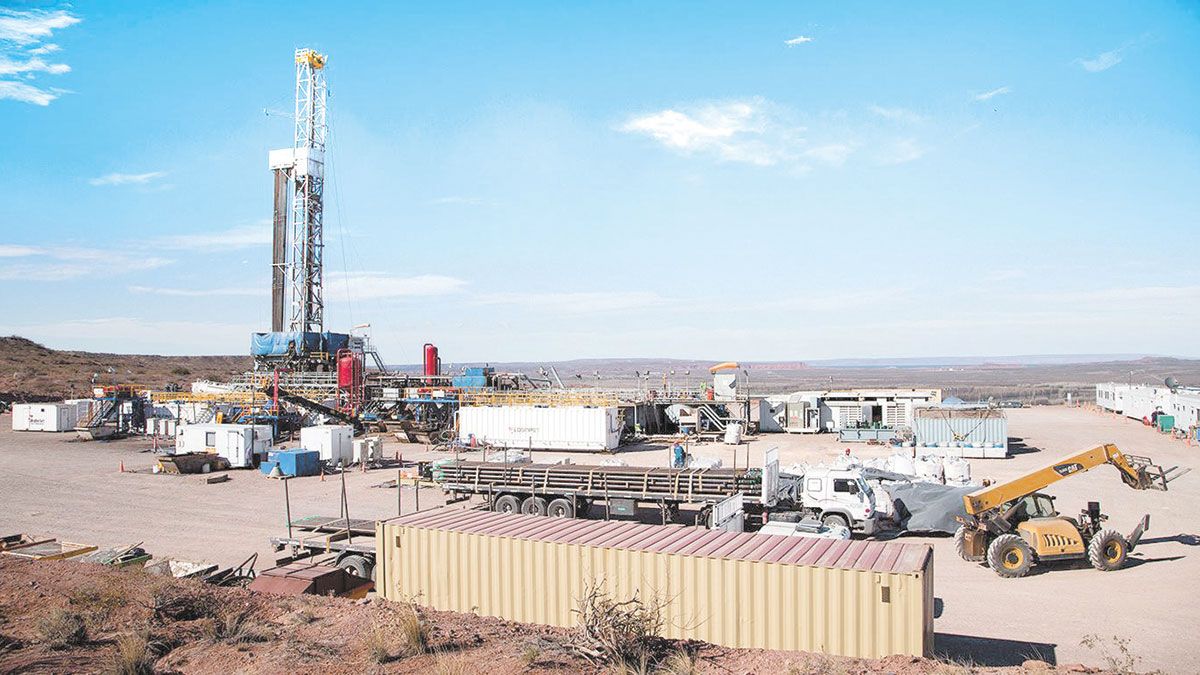

In recent years, operators have made significant progress in reducing Vaca Muerta's costs by extending the scope of horizontal drilling to the technical limits of equipment and increasing fracture stages and productivity.

The company with more activity and which has evolved the most is YPF. In Loma Campana, the main oil shale deposit in the basin, the oil company had a development cost of US $ 34 per barrel in 2015. A year later, it achieved a significant reduction of US $ 18. in 2017, it was about 15 USD, last year it fell to 11 USD and, in the first four months of this year, it was already around 9 USD, according to the calculations of the company based on new estimates of recovered resources. The goal is to reach $ 8 at the end of the year, a decrease of 76% from four years ago.

According to YPF's latest presentations to investors, at La Amarga Chica, another of the developing areas, in 2016 the cost was $ 20 and this year it is already 40% lower, that is, say about $ 12.

The continuous improvement demonstrated by the company rests on three pillars: the realization of longer wells (it already drills wells of 4000 meters of lateral branch), the geonavigation which makes it possible to lay the perforations in the most productive segment of the rock. and in factory mode. that is, having the recipe to make wells by repeatedly improving the efficiency of operations.

Although YPF, because of its level of activity, is the company that shows the most progress, the other operators have also managed to reduce costs.

p02 picture.jpg

Vista Oil & Gas, the oil company led by Miguel Galuccio, began operations this year in the Neuquino shale and, with its first eight wells, significant progress has already been made. On the second platform, the oil company improved its efficiency, reaching an average of 221 meters per day of drilling, compared to an average of 145 meters per day recorded in the first wells.

He also experienced a significant improvement in the stage of completion by increasing the average number of daily fracture stages from 5 to 7.6, which represents a 52% increase.

Other operators

Vista indicated that, as a result, the average cost of drilling and completion per well had been reduced from $ 13.8 million to $ 12.6 million. The savings result mainly from the reduction of fracture costs from $ 220,000 on the first tranche to $ 200,000 on the second.

In the second quarter of 2019, Galuccio had a lifting cost of between $ 11.8 and $ 12.6 per barrel of oil equivalent, compared to $ 14.1 for the same period of 2018.

p02 produce several stages.jpg

This decrease is mainly due to the resizing of the size of the operations, the renegotiations of contracts, the implementation of the contracting model to a team and the improvement of the efficiency of the operations, as well as the synergies generated between the base of the clbadic badets and start of the activity at Vaca Muerta in the block Bajada del Palo Oeste.

Other companies, such as Shell, started with drilling and well completion costs of about $ 15 million. Today, they are down 50%, after reproducing at Neuquén the learning of unconventional trainings in the United States and Canada.

.

[ad_2]

Source link

Naaju Breaking News, Live Updates, Latest Headlines, Viral News, Top Stories, Trending Topics, Videos

Naaju Breaking News, Live Updates, Latest Headlines, Viral News, Top Stories, Trending Topics, Videos