[ad_1]

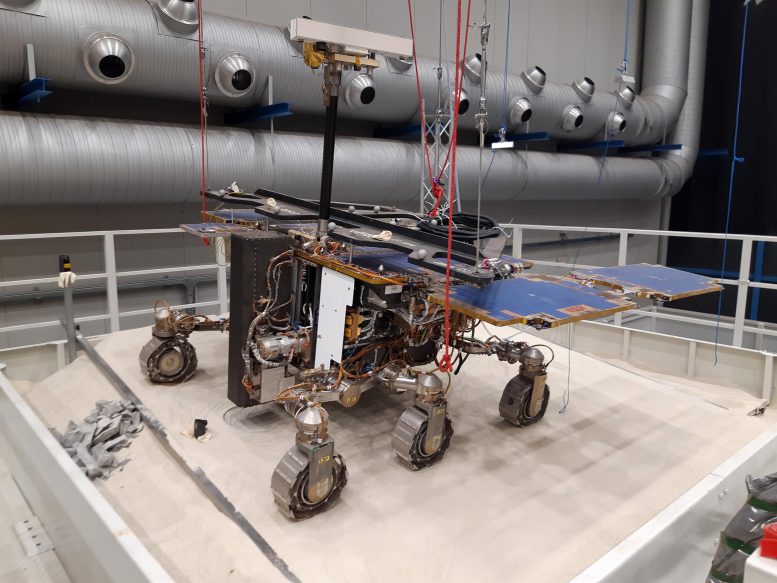

ESA’s twin rover Rosalind Franklin on Earth drilled and extracted samples 1.7 meters into the ground – far deeper than any other Mars rover has ever attempted. Credit: Thales Alenia Space

ESA’s twin rover Rosalind Franklin on Earth drilled and mined samples 1.7 meters into the ground – far deeper than any other Mars rover has ever attempted to do.

The successful collection of the soil from a hard rock and its delivery to the laboratory inside the rover marks a promising step for the ExoMars 2022 mission.

“The long-awaited success of the ExoMars drill on Earth would be a first in March exploration, ”explains David Parker, director of human and robotic exploration at ESA. The deepest depth that a drill has dug on the Red Planet to date is 7 cm.

The Rosalind Franklin rover is designed to drill deep enough, down to two meters, to access well-preserved organic material dating from four billion years ago, when conditions on the surface of Mars were more like those of the nascent Earth.

The replica, also known as the ground test model, is fully representative of the rover ready to land on Mars. The first samples were collected as part of a series of tests on Mars Terrain Simulator at the premises of ALTEC in Turin, Italy. The drill was developed by Leonardo, while Thales Alenia Space is the prime contractor for ExoMars 2022.

Drilling operations

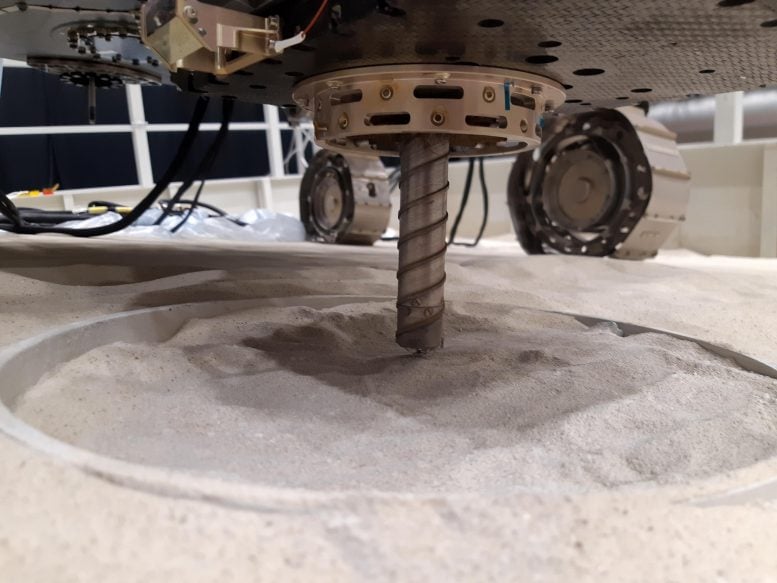

Rosalind Franklin’s twin drilled a well filled with a variety of rocks and layers of soil. The first sample was taken from a block of cemented clay of medium hardness.

The drilling took place on a dedicated platform inclined at seven degrees to simulate the taking of a sample in a non-vertical position. The drill acquired the sample in the form of a pellet about 1 cm in diameter and 2 cm long.

Tilted towards Mars. The drilling took place on a dedicated platform inclined at seven degrees to simulate the taking of a sample in a non-vertical position. The drill acquired the sample in the form of a pellet about 1 cm in diameter. Credit: Thales Alenia Space

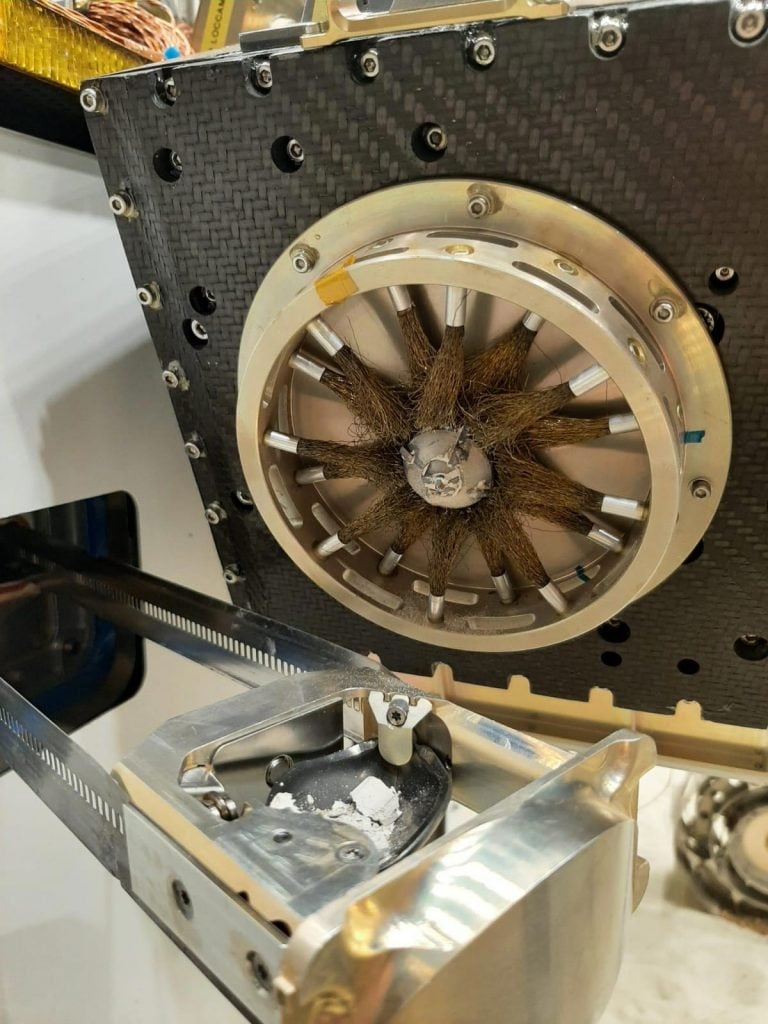

Rosalind Franklin’s drill holds the sample with an obturator that prevents it from falling during recovery. Once captured, the drill brings the sample back to the surface and delivers it to the lab inside the rover.

With the drill fully retracted, the rock is deposited into a drawer at the front of the rover, which then removes and deposits the sample at a crushing station. The resulting powder is distributed into ovens and containers designed to perform scientific analysis on Mars.

Rosalind Franklin’s drill holds the sample with an obturator that prevents it from falling during retrieval. Once captured, the drill brings the sample back to the surface and delivers it to the lab inside the rover. Credit: Thales Alenia Space

“Reliable acquisition of deep samples is key to ExoMars’ main scientific goal: to study the chemical composition – and possible signs of life – of soil that has not been subjected to harmful ionizing radiation,” Jorge explains. Vago, scientist of the ExoMars project.

A unique drill for Mars

The ExoMars drill is an assembly of mechanisms that rely on an automated choreography of tools and mounting rods. “The design and construction of the drill was so complex that this first deep hole drilling is an extraordinary achievement for the team,” said Pietro Baglioni, team leader of the ExoMars rover.

Rosalind Franklin’s drill runs in rotation. A series of tools and extension rods are installed to form a “drill string” and can reach the total length of 2m when all are connected.

Ready to drill. Credit: Thales Alenia Space

The drill can penetrate the soil at 60 revolutions per minute, depending on the consistency of the soil. Digging in solid sandy or clayey material can take between 0.3 and 30mm per minute.

The drill also has a two-degree-of-freedom positioner that allows it to unload the sample at right angles to the rover’s lab.

Not easy

“Drilling hard rock to a depth of two meters on a mobile wheeled platform with less than 100 watts of power is a complex task,” says Andrea Merlo, ExoMars Rover functional engineer at Thales Alenia Space.

Doing it on Earth is even more difficult because the ground test model must be unloaded to recreate the lowest level of Martian gravity – the gravity of Mars is about a third of that of Earth. The model is suspended from the ceiling on a dedicated gravity compensation device.

First hole drilled for the twin ExoMars rover. Credit: Thales Alenia Space

Since the twin rover consists of models that have exceeded their rated lifespans, the team had to adjust certain parameters during the deep drill test. “This is already giving engineers a clue as to how the system could degrade on Mars,” adds Andrea.

Roaming trials on Mars

The ground test model successfully passed a number of tests to move around and identify targets while acquiring images and data. These dry runs to repeat the rover’s operations on Mars began in June 2021.

The twin rover ExoMars and the Martian rocks. Credit: Thales Alenia Space

The rover has been shown to be able to follow precise tracks and monitor the environment on and below the surface with its instruments, including cameras, spectrometers, underground sounding radar and a neutron detector.

At the same time, the real Rosalind Franklin rover is preparing for its flight to Mars in almost a year – the ExoMars launch window opens on September 20, 2022.

[ad_2]

Source link