[ad_1]

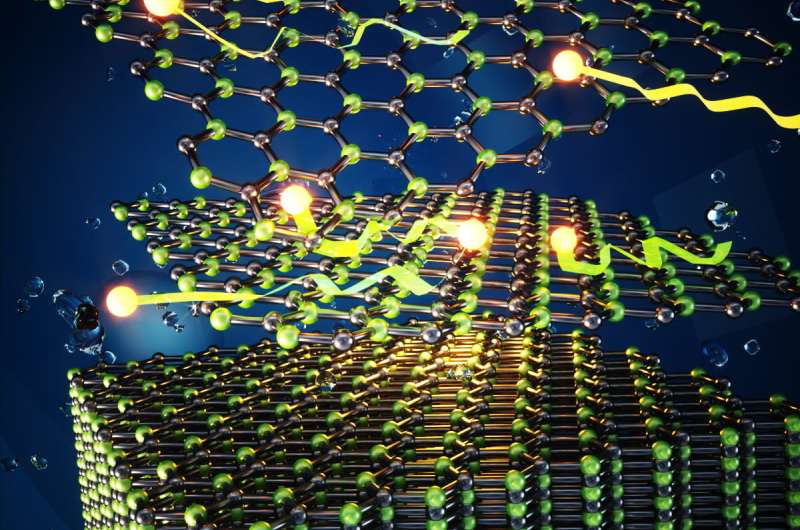

The image shows the exfoliation of hexagonal boron nitride into atomically thin nanosheets aided by surfactants, a process refined by chemists at Rice University. Credit: Ella Maru Studio

Just a little soap helps clean up the difficult process of making two-dimensional hexagonal boron nitride (hBN).

Rice University chemists have found a way to get the most quality 2D hBN nanosheets from their naturally occurring bulk form by treating them with a surfactant (aka soap) and water. The surfactant surrounds and stabilizes the microscopic flakes, preserving their properties.

Experiments conducted by the laboratory of rice chemist Angel Martí have identified the “sweet spot” for making stable dispersions of hBN, which can be made into very thin antibacterial films that withstand temperatures up to 900 degrees Celsius (1652 degrees Fahrenheit).

The work led by Martí, former Ashleigh Smith McWilliams and graduate student Cecilia Martínez-Jiménez is detailed in the Journal of the American Chemical Society Nano Applied Materials ACS.

“Boron nitride materials are interesting, especially because they are extremely heat resistant,” Martí said. “They’re as light as graphene and carbon nanotubes, but you can put hBN in a flame and nothing happens to it.”

He said bulk hBN is cheap and easy to obtain, but turning it into microscopic building blocks has been a challenge. “The first step is to be able to exfoliate them and disperse them, but research on how to do this has been scattered,” Martí said. “When we decided to set a benchmark, we found that the processes that have been extremely useful for graphene and nanotubes do not work as well for boron nitride.

Sonication of the bulk hBN in water was successful in exfoliating the material and making it soluble. “It surprised us, because the nanotubes or graphene are floating right above it,” Martí said. “The hBN dispersed everywhere, although it was not particularly stable.

“It turned out that the edges of boron nitride crystals are made up of amine and nitric oxide groups and boric acid, and all of these groups are polar (with a positive or negative charge),” he said. declared. “So when you exfoliate them, the edges are full of these functional groups that really like water. That never happens with graphene.”

Experiments with nine surfactants helped them find the right type and amount to prevent 2D hBN from clumping together without overly cutting individual flakes during sonication. The researchers used 1% by weight of each surfactant in water, added 20 milligrams of bulk hBN, then stirred and sonicated the mixture.

Spinning the resulting solutions at low and high rates showed that the greatest yield came from the surfactant known as PF88 under 100 gravity centrifugation, but the highest quality nanosheets came from all ionic surfactants under centrifugation. of 8000 g, with the greatest stability of the common ionic centrifugation. SDS and CTAC surfactants.

DTAB – short for dodecyltrimethylammonium bromide – under high centrifugation has been shown to be the best way to balance the yield and quality of 2D hBN. The researchers also produced a transparent film from hBN nanosheets dispersed in SDS and water to demonstrate how they can be turned into useful products.

“We describe the steps to be taken to produce high quality hBN flakes,” said Martí. “All the steps are important, and we were able to highlight the consequences of each.”

You’re not that hard, h-BN

Ashleigh D. Smith McWilliams et al, Understanding the Exfoliation and Dispersion of Hexagonal Boron Nitride Nanofheets by Surfactants: Implications for Antibacterial and Thermally Resistant Coatings, Nano materials applied by ACS (2021). DOI: 10.1021 / acsanm.0c02437

Provided by Rice University

Quote: A little soap simplifies the making of 2D nanoflakes (2021, January 27) retrieved January 27, 2021 from https://phys.org/news/2021-01-soap-d-nanoflakes.html

This document is subject to copyright. Apart from any fair use for study or private research, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link