[ad_1]

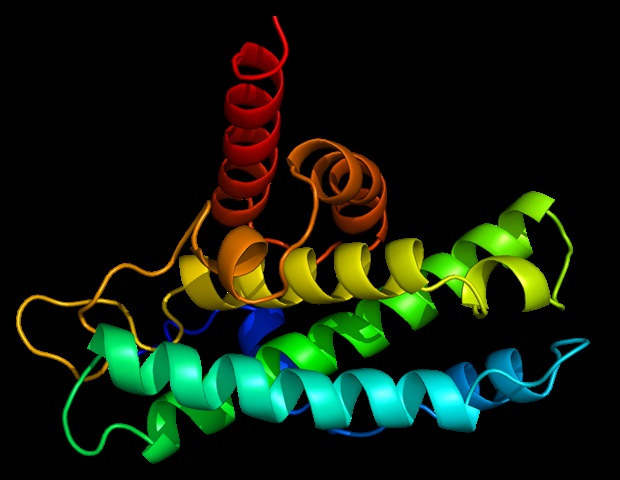

Alpha-1-antitrypsin is a protein produced by the liver. The protein is secreted in the blood, where it circulates in the body to protect the lungs.

However, some people are born with genetic disorders that hinder the production of this protein. These patients may suffer from a decrease in lung function, liver disease and shortness of breath.

In the United States and in other countries, the disorder is currently being treated with human plasma fractions containing alpha-1-antitrypsin. The treatment requires an infusion of about four grams of protein per pr. the week. To obtain this dose, blood from 900 donors is needed and the treatment costs about $ 100,000 per year, pr. patient.

Now, a group of researchers from the Center for Biosupportability of the Novo Nordisk Foundation of the Technical University of Denmark has found a way to produce this protein in mammalian cells.

"The current production of Alpha-1-antitrypsin from blood requires a significant and constant supply of donor blood.With a recombinant alternative, you can both formulate the product, concentrate the protein, purify it and avoid it. the dependence of blood donors, we would be able to ensure security of supply, "said Bjørn Voldborg, director of development of the CHO cell line at the Novo Nordisk Foundation's Biosurability Center.

CHO cells can produce more than one gram

Researchers have successfully produced alpha-1-antitrypsin in CHO cells, one of the most used cell lines for the production of human therapeutic proteins. Normally, the glycosylation profile of the CHO of alpha-1-antitrypsin is quite different from that of the human homolog. The human version of alpha-1-antitrypsin has a very specific sugar structure, whereas if it is produced in CHO cells, it presents a variety of sugars, making the protein ineffective in the human body.

The researchers obtained this glycosylation profile by introducing a human gene coding for an enzyme capable of decorating the sugar skeleton of the Alpha-1-antitrypsin proteins with the appropriate human fragments. In addition, they removed a number of natural glycosylation genes from CHO cells using CRISPR-Cas9.

This effort resulted in a cell line capable of producing more than 1.2 grams per day. 1 liter of CHO cells in culture, which allows to produce alpha-1-antitrypsin from CHO cells on a scale to eliminate the need for human donors in the future.

"This is really a step in the right direction when we are looking at the production of glycosylated therapeutic proteins, and we are convinced that we can further improve the yield, which will make this product commercially attractive to the pharmaceutical industry," says Bjørn Voldborg. .

Today, CHO cells with the best yield produce about 10-12 g / L of monoclonal antibodies. Therefore, this cell line producing Alpha1-antitrypsin still produces only about 10% of this known maximum. One of the next steps is therefore to further improve performance.

Good prospects for the future

The natural alpha-1-antitrypsin degrades quite rapidly in the body. In the future, researchers want to improve the stability of recombinant proteins. Thus, patients with alpha1-antitrypsin deficiency would require fewer injections. As a result, this new knowledge of glycosylation profiles opens a new window for optimizing human proteins to improve their stability and function.

"Our hope is to optimize stability and become so gifted for the design of glycans that researchers and companies can order glycan structures to any protein. This will speed up the production of new glycosylated proteins." for therapeutic use, "said Bjørn Voldborg.

Source:

http://www.biosustain.dtu.dk/nyhedsbase/nyhed?id=3AA1F90B-3ECD-4093-AF56-420BD9F43D55

[ad_2]

Source link