[ad_1]

SpaceX today announced that the construction projects of BFR (now known as Starship / Super Heavy) in the Port of Los Angeles have at least been initially replaced by a decision to transfer this development to the south of Texas, although details regarding new facilities and their schedule remains to be shared.

In conclusion, this could mean that SpaceX no longer intends to build a BFR facility in the Port of Los Angeles, while all Falcon 9 / Heavy, Merlin and Raptor manufacturing sites will remain at the company's headquarters at Hawthorne, California, for a predictable period. future. However, the statements do not exclude the possibility that SpaceX is still considering developing an oceanfront plant for Super Heavy, Starship, or both.

SpaceX will no longer manufacture its Mars Spacecraft and Rocket Propellant at the Port of Los Angeles. Instead, the work will be done in South Texas. https://t.co/LqBfPawiZf

– Los Angeles Times (@latimes) January 16, 2019

Update: CEO Elon Musk said on Twitter that the Los Angeles Times' original report and a partial miscommunication on behalf of SpaceX had misinterpreted an official statement claiming that the construction and development of the Starship and Super Heavy prototypes in phase startup would remain in South Texas for the moment. It seems that the plans of the Los Angeles port of SpaceX remain largely unchanged.

The source information is incorrect. The development of Starship & Raptor is underway from our head office located in Hawthorne, California. We are building Starship prototypes locally at our Texas launch site because their size makes them very difficult to transport.

– Elon Musk (@elonmusk) January 16, 2019

"To streamline operations, SpaceX is developing and testing the Starship test vehicle at our site in South Texas. This decision has no impact on our current manufacturing, design and launch activities at Hawthorne and Vandenberg Air Force Base in California. In addition, SpaceX will continue the recovery operations of our Falcon rockets and our reusable Dragon spacecraft at the Port of Los Angeles. "- SpaceX, January 16, 2019

In early 2018, SpaceX announced that it needed a new berth at the port of San Pedro with the specific intention of building a brand new BFR facility. By keeping BFR production in Los Angeles and placing it directly beside the mode of transportation of choice (a barge from California to Texas), the official hope was to retain the best aerospace talent in the States. United States (generally concentrated around central California) and to ensure that its main Hawthorne plant is a few minutes' drive away, while still providing relatively affordable bulk BFR vessels up to 9 m in diameter and boosters between California and Texas.

Speaking also in 2018, Operations Director and President Gwynne Shotwell reported that the estimated cost of moving a BFR-sized object from its main Hawthorne facility to the Port of Los Angeles would be an average of $ 5 million. dollars for a journey without return. For the context, this represents almost 10% of the price displayed of a brand new Falcon 9 rocket ($ 62 million), just to perform the basic logistics required. As a result, SpaceX decided to build a permanent factory on a wharf in the port of Los Angeles, where the company had already mounted a giant tent to begin manufacturing a prototype. Known as Berth 240, it is now unclear whether SpaceX will and will continue to transform the land of San Pedro harbor into a permanent facility with a construction cost of a few tens of millions of dollars.

SpaceX is currently using Pier 240 as the base of operations for the Faircleaning Recovery Vessel, Mr. Steven. (Pauline Acalin)

Most of the Berth 240's grounds present decrepit but historic buildings dating back to the early 20th century – SpaceX is required by its EIS to help preserve them and can only demolish a small shed. (Pauline Acalin)

Over the last six months, SpaceX has VERY progressively prepared the foundations for its future Berth 240 plant, although little visible progress has been made. (Pauline Acalin, 30/11/18)

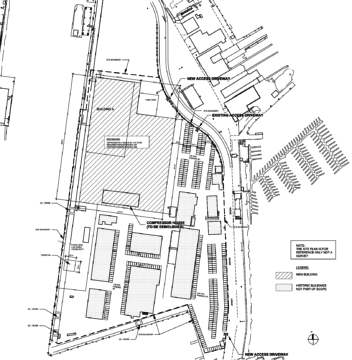

Plans for the future BFR plant proposed at 240 berth. (SpaceX)

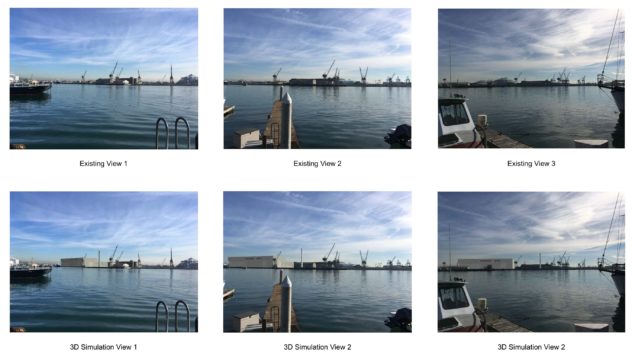

Renders of the BFR plant project at berth 240. (SpaceX)

An overview of the two planned stages of construction of the BFR plant, March 2018. (SpaceX)

In the company's approved environmental impact badessment, the implication was that the BFR plant could also serve as a dedicated post-recovery recovery and recovery facility for the usual Falcon 9 missions and provide much more spacious for drone ships. . This type of facility could still provide significant value for SpaceX, although it might not make enough money to account for the redundancy related to the renovation in LA's port instead of just sending boosters. Falcon 9 recovered from the main server. The main Hawthorne factory, which can simultaneously accommodate the renovation of at least two Falcon 9 boosters.

Starship Hopper has been disbadembled again (for the installation of the partition etc.)

BocaChicaGalhttps from ?NSF: //t.co/DlTj9Qiijz

NSF Overview News Article by Thomas Burghardt @ TGMetsFan98 for those who are catching up: https: //t.co/rgliFAkBMC pic.twitter.com/DzSJzjSvoI

– Chris B – NSF (@NASASpaceflight) January 15, 2019

SpaceX may also want to have Los Angeles facilities capable of supporting the development and production of Starship and Super Heavy structures at a lower cost in the event that some of its excellent engineers and technicians would not be interested in moving from Los Angeles to the sparsely populated southeast end of Texas. In the meantime, the company continues to work toward the completion of its first prototype flight (ish) Starship at its rapidly expanding facility in South Texas, with CEO Elon Musk indicating that vehicle testing could start in February or March 2019.

Expect very soon a new article on the recent progress of the Starship hopper!

Check out Teslarati newsletters for quick updates, on-the-ground perspectives and unique insights into SpaceX rocket launch and recovery processes!

[ad_2]

Source link