[ad_1]

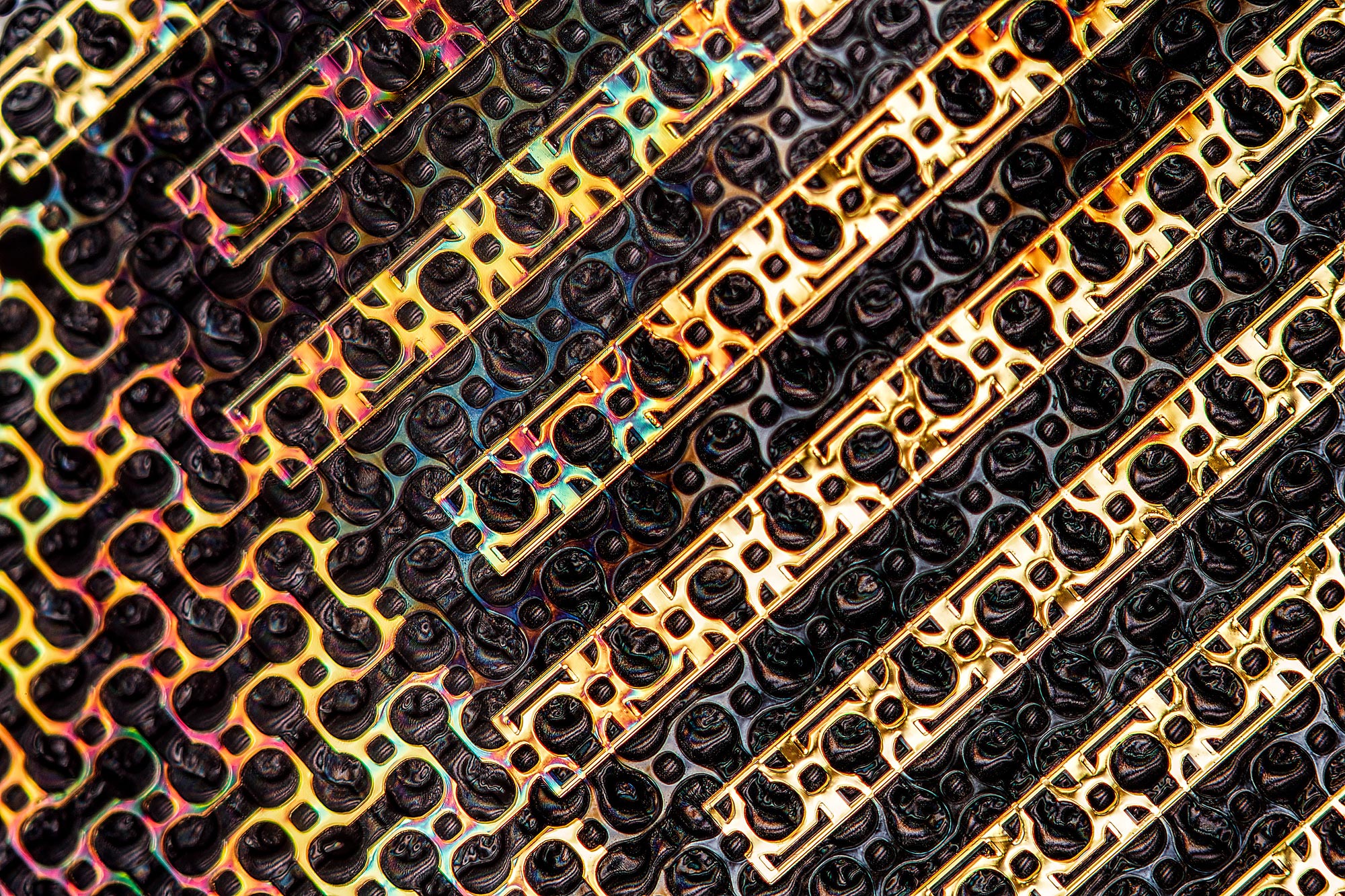

Engineers developed a sweat-resistant “electronic skin” – a conformable, sticky patch built into a sensor that reliably monitors a person’s health, even when they are sweating. The patch contains artificial sweat ducts through the ultrafine layers of the material, shown. Credit: Felice Frankel

The design could lead to conformable portable monitors to track skin cancer and other conditions.

Engineers and researchers at MIT in South Korea have developed a sweat-resistant “electronic skin” – a conformable, sticky patch built into a sensor that monitors a person’s health without malfunction or peeling, even when the wearer is sweating.

The patch is patterned with artificial sweat ducts, similar to pores in human skin, which the researchers etched through the ultra-thin layers of the material. The pores perforate the patch in a kirigami-like pattern, similar to that of the Japanese art of paper cutting. The design ensures that sweat can escape through the patch, preventing skin irritation and damage to the built-in sensors.

The design of the kirigami also helps the patch conform to human skin when it stretches and bends. This flexibility, coupled with the material’s ability to resist sweat, allows it to monitor a person’s health over long periods of time, which was not possible with previous “e-skin” designs. The results, published on June 30, 2021, in Scientists progress, are a step towards long-lasting smart skin that can track daily vital signs or the progression of skin cancer and other conditions.

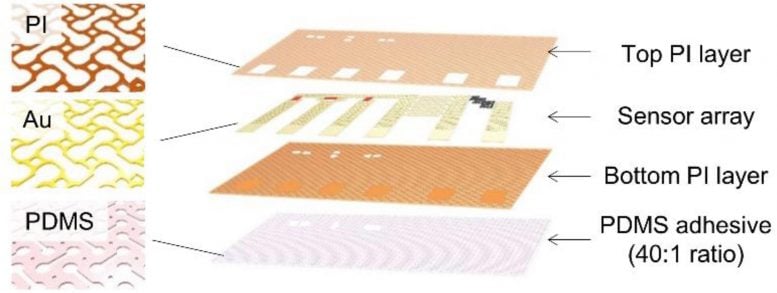

Schematic illustration of perforated e-skins. Credit: Courtesy of the researchers

“With this conformable and breathable skin patch, there will be no sweat buildup, misinformation or peeling of the skin,” says Jeehwan Kim, associate professor of mechanical engineering at MIT. “We can provide portable sensors that can perform constant long-term monitoring. “

Kim’s co-authors include MIT Senior and Postdoctoral Fellow Hanwool Yeon, and researchers from the Mechanical Engineering and Materials Science and Engineering Departments of MIT, and the Electronics Research Laboratory, as well as collaborators from the conglomerate. Amorepacific cosmetics and other institutions across South Korea.

A sweaty obstacle

Kim’s group specializes in manufacturing flexible semiconductor films. Researchers have developed a technique called remote epitaxy, which involves growing ultra-thin, high-quality semiconductor films on wafers at high temperatures and selectively removing the films, which they can then combine and stack to form sensors that are much thinner and more flexible than conventional wafers. based designs.

Recently, their work caught the attention of cosmetics company Amorepacific, which was interested in developing a thin portable adhesive tape to constantly monitor skin changes. The company has partnered with Kim to shape the group’s flexible semiconductor films into something that could be worn over long periods of time.

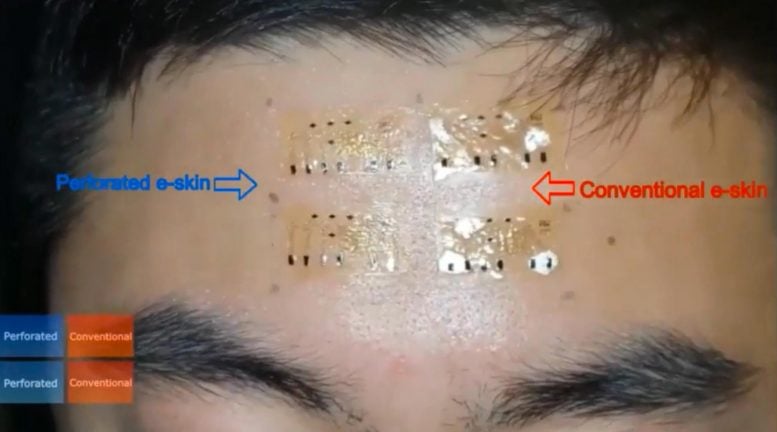

The researchers tested the electronic skin by sticking it to a volunteer wrist and forehead for a week. The volunteer wore the ribbon during sweating activities, such as running on a treadmill for 30 minutes and eating a spicy meal, in the photo. Credits: Image: Video always courtesy of the researchers

But the team quickly ran into a hurdle that other models of electronic skins have yet to overcome: sweat. Most experimental designs incorporate sensors into sticky, polymer-based materials that are not very breathable. Other models, made from woven nanofibers, can pass air, but not sweat. If electronic skin was to work for the long haul, Kim realized that it would have to be permeable not only to vapor, but to perspiration as well.

“Sweat can build up between the electronic skin and your skin, which could damage the skin and cause the sensor to malfunction,” Kim explains. “So we tried to solve these two problems at the same time, by allowing the sweat to penetrate through the electronic skin.”

Make the cut

For inspiration for the design, the researchers looked to human sweat pores. They found that the average pore diameter is around 100 microns, and the pores are distributed randomly throughout the skin. They did some initial simulations to see how they could layer and arrange artificial pores, in a way that wouldn’t block actual pores on human skin.

“Our simple idea is that if we provide artificial sweat ducts in the electronic skin and create highly permeable paths for sweat, we can achieve long-term monitoring,” says Yeon.

They started with a periodic pattern of holes, each the size of an actual sweat pore. They found that if the pores were close together, at a distance less than the average diameter of a pore, the pattern as a whole would effectively permeate the sweat. But they also found that if this simple pattern of holes was etched through a thin film, the film was not very stretchable and it easily broke when applied to the skin.

The researchers found that they could increase the strength and flexibility of the hole pattern by cutting thin channels between each hole, creating a repeating dumbbell pattern, rather than simple holes, which relax the tension, rather than the focus in one place. This pattern, when etched into a material, creates a stretchy effect similar to that of a kirigami.

“If you wrap a piece of paper on a ball, it’s not conformable,” Kim says. “But if you cut a kirigami pattern from the paper, it could conform. So we thought, why not connect the holes with a cut, to have kirigami-like conformability on the skin? At the same time, we can impregnate the sweat.

Following this logic, the team made an electronic skin from multiple functional layers, each etched with dumbbell patterned pores. The layers of the skin include an array of ultrathin patterned semiconductor sensors to monitor temperature, hydration, UV exposure, and mechanical stress. This array of sensors is sandwiched between two thin protective films, all of which cover a tacky polymer adhesive.

“Electronic skin is like human skin – very stretchy and soft, and sweat can soak into it,” Yeon explains.

The researchers tested the electronic skin by sticking it to the wrist and forehead of a volunteer. The volunteer wore the band continuously for a week. Throughout this time, the new e-skin reliably measured his temperature, hydration level, UV exposure and pulse, even during activities that induce sweating, such as running on a treadmill. for 30 minutes and consume a spicy meal.

The team’s design was skin-conforming as well, sticking to the volunteer’s forehead as they were asked to repeatedly frown while sweating profusely, compared to other electronic skin designs that lacked permeability. perspiration and came off easily from the skin.

Kim plans to improve the strength and durability of the design. While the tape is both breathable and highly conformable, thanks to its kirigami pattern, it is this same pattern, combined with the ultra-thin shape of the tape, that makes it quite fragile to friction. As a result, volunteers had to wear a holster around the ribbon to protect it during activities such as showering.

“Because electronic skin is very soft, it can be physically damaged,” Yeon explains. “We aim to improve the resilience of electronic skin. “

Reference: “Reliable Long-Term Physical Health Monitoring Using Perforated Electronic Skins Inspired by Sweat Pores” by Hanwool Yeon, Haneol Lee, Yeongin Kim, Doyoon Lee, Youngjoo Lee, Jong-Sung Lee, Jiho Shin, Chanyeol Choi, Ji-Hoon Kang, Jun Min Suh, Hyunseok Kim, Hyun S. Kum, Jaeyong Lee, Daeyeon Kim, Kyul Ko, Boo Soo Ma, Peng Lin, Sangwook Han, Sungkyu Kim, Sang-Hoon Bae, Taek-Soo Kim, Min -Chul Park, Young-Chang Joo, Eunjoo Kim, Jiyeon Han and Jeehwan Kim, June 30, 2021, Science.

DOI: 10.1126 / sciadv.abg8459

This research was supported by Amorepacific.

[ad_2]

Source link