[ad_1]

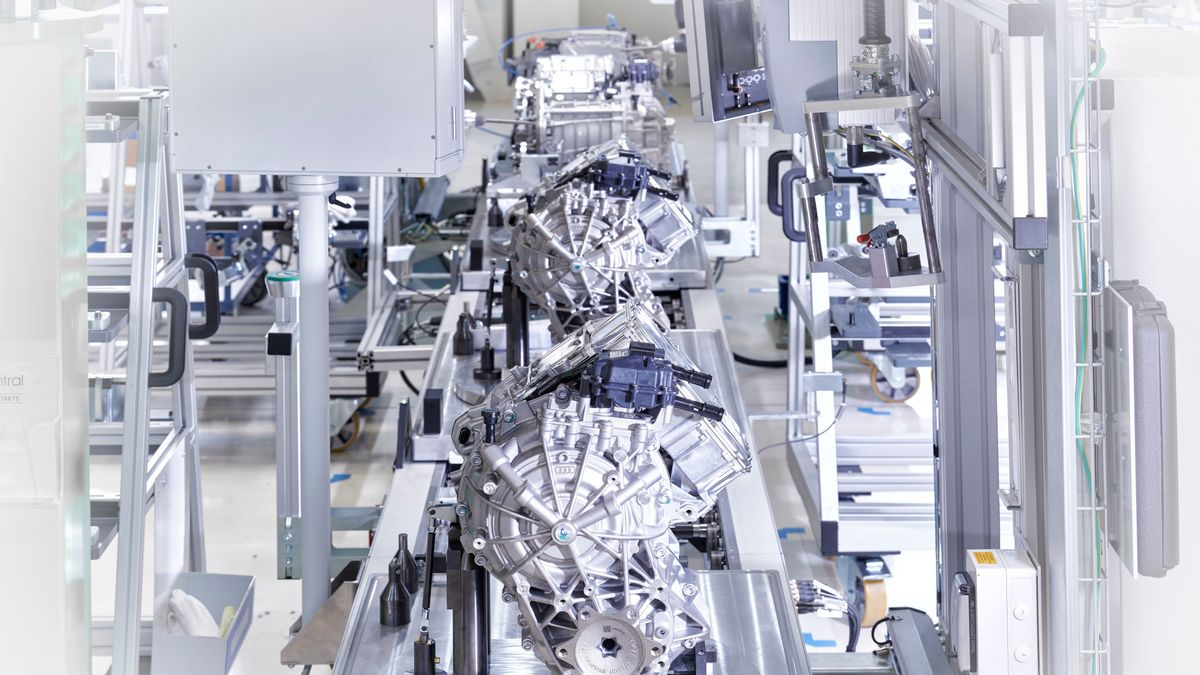

Audi reports that it began mass production of electric motors at its Győr plant in Hungary. The engines produced here will be used in future Audi electric cars, like E-Tron Quattro.

The factory has up to now been one of the world's largest combustion engine manufacturers. Last year, nearly two million internal combustion engines were manufactured in the production plant of Audi in Hungary, all cars of the Volkswagen Group.

They call it a milestone and the beginning of a new era. The electric motors are manufactured in a production hall of 8500 square feet, where 100 people work on the construction of new engines

Must be particularly effective

Audi says that the engines produced here should be particularly effective. Indeed, the stator (on the outside, or the part of the motor that does not move) is particularly packed with stator windings, according to the manufacturer. "src =" https://img.gfx.no/2322/2322976/A188591_large.330×235.jpg "/>

It is an enamelled copper wire that creates the magnetic fields that move the moving part of the electric motor – the rotor – in motion. The engine is part of the Audi called electric shaft, which includes other components such as power electronics, gear and differential.

Two types per car are used, as the E-Tron Quattro will have a modular all-wheel drive

which means that each production station is not connected to a conveyor belt. This will give greater freedom of production because the different parts of the engines can be manufactured separately

The parts will be transmitted to the next station by means of a driverless transport vehicle.

400 engines per day

The production capacity is 400 engines per day, but this can be increased if necessary.

However, the Volkswagen Group starts producing electric motors in Hungary. positioning itself for a future that will increasingly consist of electric cars.

- Learn more about electric cars.

[ad_2]

Source link