[ad_1]

Researchers at the Massachusetts Institute of Technology (MIT), in collaboration with chip maker Analog Devices, have successfully created the world's first fully functional and programmable 16-bit processor to be built from carbon nanotubes – and used the Open RISC-V set architecture (ISA) instruction to do that.

Moore's Law Walk – the observation turned into absolute command that the number of transistors on a semiconductor portion at the cutting edge of technology tends to double every 18 months – is not easy. As the number of transistors increases, the size of the components must decrease – as we fall to 10 nm and below the physics begins to hinder, as can testify Intel and GlobalFoundries. One of the areas of research to improve the situation is the replacement of silicon semiconductors by other materials, carbon nanotubes being one of the relatively exotic substances proposed to replace the silicon chip.

In 2013, researchers at Stanford University had developed the first carbon nanotube processor, using a 1000 nm process node and integrating only 142 transistors in the test chip – enough to implement a small subset of the MIPS Instruction Set Architecture (ISA) and create what they claimed. Be the first Turing-complete carbon nanotube computer.

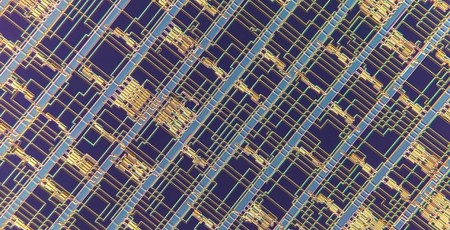

Now, MIT and Analog Devices have announced the result of their own efforts in carbon nanotube-based semiconductors: a more impressive 16-bit chip with 14,000 nanotube field effect transistors (CNFETs) Carbon implementing the 16-bit version of the open RISC-V instruction set architecture.

& # 39;It is by far the most advanced chip from emerging nanotechnology, promising for high-performance, energy-efficient computing,"Says Professor Max M. Shulaker about the creation of his team. & # 39;There are limits to silicon. If we want to continue to progress in computing, carbon nanotubes are one of the most promising ways to overcome these limitations. [This paper] completely reinvent the way we build chips with carbon nanotubes.& # 39;

The team's search processor was produced using a new technique, called Resistance Design against Metal CNTs (DREAM), which dramatically reduced the number of defects occurring during production, which previously prevented large-scale production of CNFET. With its RISC-V ISA, the team's RV16XNano chip is able to do everything that a commercial silicon microprocessor can do – albeit much more slowly, for the moment. As proof, the team asked the chip to come with a printed message: & # 39;Hi world! I am RV16XNano, made from CNT.& # 39;

As with many post-silicon research projects, the team remains silent on the timing of commercialization, although it has already signed an agreement with the Defense Advanced Research Projects Agency (DARPA) for the implementation of DREAM in a silicon chip foundry. & # 39;We think that it is no longer a question of whether,"says Professor Shulaker on the subject of marketing CNFET,"but when.& # 39;

The team's work was published in the journal Microprocessor Modern, built from complementary transistors of carbon nanotubes. Nature.

[ad_2]

Source link