[ad_1]

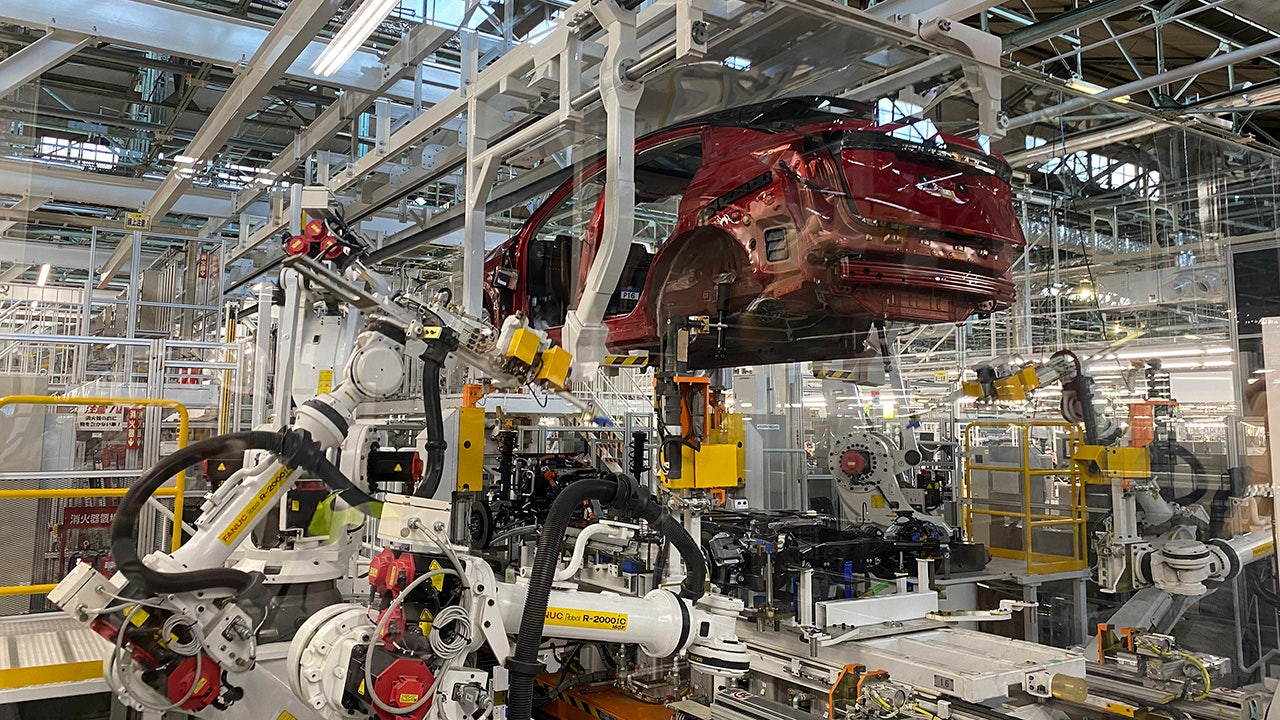

Robotic arms integrated into the Ariya model electric vehicle’s powertrain on the assembly line at Nissan’s Tochigi plant in Kaminokawa city, Tochigi prefecture, Japan on Friday, October 8, 2021 (AP Photo / Yuri Kageyama)

KAMINO KAWA, Japan – Nissan’s “smart factory” has virtually no human workers. The robots do the work, including welding and assembly. They do the paint jobs and inspect their own paint jobs.

“Until now, people had to make production adjustments through experience, but now robots with artificial intelligence, analyzing the data collected, are able to do it. level, ”said Nissan executive vice president Hideyuki Sakamoto during a tour. production line of the Ariya sport utility vehicle at its Tochigi plant on Friday.

The plant, on the outskirts of Tokyo, is expected to be operational by April, according to Nissan Motor Co.

Its assembly line is designed so that the three types of models – electric; e-Power, which has both an engine and an engine, and those powered by a regular combustion engine – can be built on the same line. Each vehicle is equipped with the right powertrain as it moves along the line.

Are robots the future of recycling?

Recycling is a simple thing we all do to try to protect the environment, but it’s also big business. But in 2021, the industry is experiencing dramatic changes, all fueled by artificial intelligence.

Plant workers can focus on more skilled jobs such as analyzing data collected by robots and maintaining equipment.

All car manufacturers are working on robotic technology that can increase adaptability and enable them to respond quickly to market demand.

During the visit, giant mechanical arms fitted with large screens shone the light from the screens onto the surfaces of the car from different angles so that the cameras could detect even the smallest flaws.

A mechanism quickly wrapped wires around a metallic object that looked like a giant coil, an engine part that Nissan uses to replace magnets now used in electric vehicles. The company claims that the innovation eliminates the need for rare earth materials, thereby reducing costs.

Nissan said the innovations tested at Tochigi will be gradually rolled out to its other global factories, including the factories of Renault, a partner of the French alliance.

A robot plane unveiled

A San Francisco-based aircraft technology company tested a freighter that operates autonomously. It starts its engine, rolls, takes off, cruises, lands, rolls and stops its engine with little or no human intervention. (Video source courtesy of Xwing)

Sakamoto said it was difficult to estimate exactly how much the fully automated assembly line will save.

But he said manufacturing must adapt to labor shortages, the coronavirus pandemic and reduce carbon emissions to help mitigate climate change.

Nissan says that by 2050 it hopes to achieve carbon neutrality in all of its operations and the lifecycle of its products, which includes the extraction, manufacture, use and recycling of raw materials.

A new type of paint that allows vehicle bodies and bumpers to be painted and baked simultaneously reduces energy consumption by 25%, according to the company.

NYPD robotic K9

The New York Police Department is testing a robotic dog, so to speak. The device raided an apartment in the Bronx.

Previously, vehicle bodies, which are made of aluminum, and plastic bumpers had to be painted separately at different temperatures.

Nissan expects to return to profitability this fiscal year, but like other automakers, it faces parts shortages caused by the pandemic. His brand has been hit by a scandal centered on its former president, Carlos Ghosn, who was arrested in Japan for financial misconduct in 2018.

[ad_2]

Source link