[ad_1]

Tesla CEO Elon Musk said the current semiconductor crisis will be over by next year.

Musk thinks the crisps shortage is a “short-term” problem. “There are a lot of chip making factories under construction and I think we will have good capacity by next year,” he said at an Italian tech conference broadcast online on Friday.

Although Musk has not specified specific factories, heavy-chip companies Intel and TSMC have announced plans to build new factories in the United States, but they will not be operational for several years.

Glenn O’Donnell, deputy director of research at Forrester Consulting, estimates the shortage could continue until 2023.

“Given that demand will remain high and supply will remain limited, we expect this shortage to continue through 2022 and into 2023,” he wrote in a blog in April.

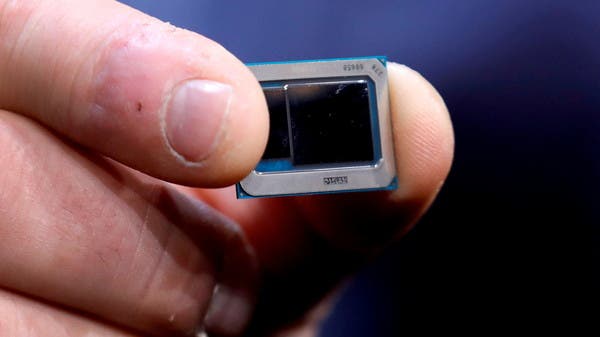

The global chip shortage has had a major impact on a wide range of industries, but the automotive sector has been hit particularly hard. Big names in the industry such as Ford, Volkswagen and Daimler have been forced to repeatedly halt production and lower their manufacturing targets due to chip shortages.

Impact on Tesla

During the company’s first quarter results, Musk said Tesla had supply chain issues, before moving on to a chip shortage, which he referenced in his second quarter results.

And consulting firm AlixPartners predicted this week that the chip shortage will cost the auto industry $ 210 billion in revenue this year alone.

The flea crisis could continue until 2023

Alex Partners’ global co-leader Mark Wakefield said: “Of course everyone was hoping the chip crisis would abate further now, but unfortunate events such as the new coronavirus lockdown in Malaysia and the ongoing problems elsewhere have only exacerbated matters. “

Automakers use semiconductors for everything from power steering and brake sensors to entertainment systems and parking cameras. The smarter the cars, the more they are used.

In 2019, Tesla started producing cars with custom AI chips that help onboard software make decisions in response to what’s happening on the road.

Musk said in July that production of Tesla’s Powerwall product, a home backup battery, was “behind schedule” due to a lack of chips.

Source link