[ad_1]

Illustration: Marek Denko / NoEmotion

We are in 2038. After 18 months of life and work on the surface of Mars, a crew of six explorers board a space rocket and depart for Earth. No humans are left behind, but the work continues without them: autonomous robots will continue to operate a chemical and chemical synthesis plant that they started years before this first crewed mission ever put them on the road. feet on the planet. The factory produces water, oxygen and fuel for rockets using local resources. It will methodically build all the necessary supplies for the next mission to Mars, which is expected to arrive in two years.

This robot factory is not science fiction: it is developed jointly by several NASA teams. One of them is the Swamp Works Lab at NASA's John F. Kennedy Space Center in Florida, where I am a team leader. Officially, it is an in situ resource utilization system (ISRU), but we like to call it factory because it turns a simple dust into rocket fuel. This technology will one day allow humans to live and work on Mars – and return to Earth to tell the story.

But why synthesize elements on Mars instead of shipping them from Earth? NASA invokes the "transmission ratio problem". According to some estimates, to carry a kilo of fuel from Earth to Mars, the current rockets must burn 225 kilos of fuel in transit: they launch into a low Earth orbit, move to Mars and slow down to enter Martian orbit, then slow down to land safely on the surface of Mars. We would start with 226 kg and finish with 1 kg, which gives a transmission ratio of 226: 1. And the ratio stays the same no matter what we ship. We would need 225 tons of fuel to send a ton of water, a ton of oxygen or a ton of machinery. The only way to get around this severe arithmetic is to use our water, our oxygen, and our fuel on site.

Different NASA research and engineering groups have been working on different parts of this problem. More recently, our Swamp Works team began integrating many distinct work packages to demonstrate the entire closed-loop system. It's still a prototype, but it shows all the parts needed for our dust factory to become a reality. And although the long-term plan is on Mars, NASA is focusing its attention on the moon. Most of the equipment will first be tested and developed on the lunar surface, which will help reduce the risks associated with sending them to Mars.

Dirt or dust on every celestial body is commonly called regolith. It is most often volcanic rock that has been crushed or altered over time into a fine powder. On Mars, under a layer of rusty ferrous minerals that gives the planet its famous reddish hue, lies a thicker layer of silicates with names such as feldspar, pyroxene and olivine, made up of silicon and oxygen structures bonded to metals such as iron, aluminum and magnesium.

The excavation of this material is difficult because its consistency and compactness vary from one place to another on Mars. But what makes the task even more difficult is the low gravity of the planet, which makes it difficult to push a shovel into the ground without using your weight to counteract this force. On Earth, when we dig in the ground, we often use large vehicles, as their heavy bodies respond appropriately to the forces of the digging bucket much smaller. But remember the problem of the transmission ratio: every ounce launched on Mars is precious and very expensive. So we had to find a way to dig on the surface of Mars with very light equipment.

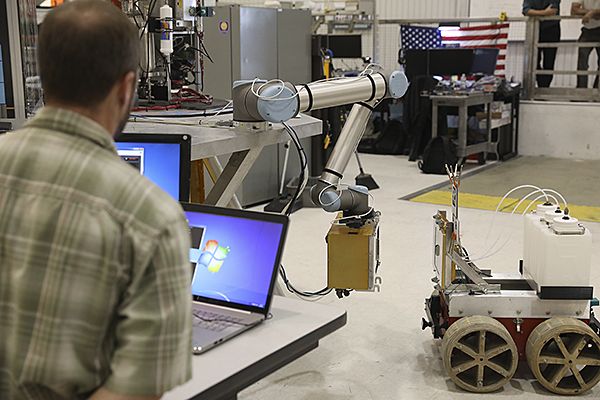

Photo: Glen Benson / NASA

Enter RASSOR, or Regolith Advanced Surface System Operations Robot, an autonomous mining vehicle designed for a specific purpose: digging or excavating the regolith in low gravity conditions. When designing RASSOR, said the "razor", NASA engineers paid close attention to its actuation system. Robot actuators include motors, gearboxes, and other mechanisms that account for a large percentage of the final mass of the system. In our design, we used frameless motors, electromagnetic brakes, and 3D printed titanium housings, among other things, to keep weight and volume to a minimum. This effort has paid off: our design is about half the mass of current standard actuators with similar characteristics.

To dig, RASSOR uses two opposed bucket drums, each equipped with several small spoons to dig. When RASSOR's bucket drums spin and the arms holding them down, they only collect a small amount of regolith in each dig as it moves slowly. This creates a shallow trench rather than a deep hole. These rotating bucket and digger drums are hollow inside, allowing them to collect and retain the excavated regolith. Another key feature of RASSOR is that while digging, bucket drums rotate in opposite directions. This cancels out a large part of the digging forces and will allow RASSOR to carry out low gravity excavations.

Once RASSOR has filled his cans, he raises his arms and goes to a processing plant. To unload the regolith, the robot simply turns the drums in the opposite direction and the regolith comes out of the same teaspoons where it entered. Another piece of equipment, a robotic hopper lift arm, handles the next task. He lifts a load of regolith on the deck of the plant and transfers it to an oven that closes and begins to heat up. All the water molecules attached to the regolith are driven off by a dry gas blower and then collected using a cold finger called a condensing tube.

You may be asking, "But is not the regolith of Mars dry?" The answer is … it's complicated. It mostly depends on where you dig and how deep you dig. Some areas on Mars seem to have almost solid ice sheets a few feet below the surface. At low latitudes, there are gypsum sand dunes composed of about 8% by weight of water.

Once cleared of water, the regolith is thrown to the ground so that the RASSOR robot can pick it up and carry it. This "waste" can actually be used for building protective structures or even roads and landing strips, using the 3D printing methods currently under development at NASA.

All water which is taken from the regolith is then purified. The cleaning module uses a multi-stage filtration system with several deionization beds.

Water is not just for drinking; it is also the key ingredient of rocket fuel. By dividing the H2O molecules with an electrolyser in gaseous hydrogen molecules (H2) and gaseous oxygen molecules (O2), then compressing and liquefying these two gases separately, we can synthesize the fuel and oxidant most commonly used in liquid fuel rocket engines.

The problem is that liquid hydrogen has to be stored at extremely low temperatures. That's why NASA plans to turn hydrogen into a much easier fuel to store: methane (CH)4) You can get it by combining hydrogen and carbon. But where do we get carbon on Mars?

Fortunately, Mars has a lot of carbon. The Martian atmosphere is composed of 96% of carbon dioxide molecules. Capturing this carbon is the job of a carbon dioxide freezer; it basically makes dry ice out of nothing.

Once we have collected the gaseous hydrogen from the electrolyser and the carbon dioxide from the atmosphere, we can combine them into methane through a chemical process called the Sabatier reaction. A special reactor designed by NASA creates the pressure and temperature needed to maintain this reaction and turn hydrogen and carbon dioxide into methane, with water as a byproduct.

The next equipment of our factory is a robotized umbilical arm to transfer fluids to an external tank truck. The peculiarity of this system is that its umbilical is specially designed to prevent dust from entering. The regolith dust is very fine and penetrates everything. And since the regolith is composed of crushed volcanic rock, it is very abrasive and hard enough for the material. (NASA's lunar missions have shown that the regolith is at the root of many problems, including false instrument readings, clogged mechanisms, seal failures, and thermal control problems.) essential to keep it away from umbilicals, electrical connectors and fluids and any sensitive electronics.

Photos: Glen Benson / NASA

Each side of the umbilical contains a set of doors that acts as an airlock to prevent dust from entering. Making a connection requires three distinct steps: the first is to squeeze the closed doors on each side, so that a special perimeter seal creates a completely dust-proof barrier around the two sets of umbilical gates. In the second step, the doors located on either side of the umbilical interface open inside the dust seal, thus revealing the actual connectors, mounted on a movable plate. The last step is to move the plates together and physically assemble all the power, electrical and fluid connectors.

A robotic arm aboard the rocket fuel plant will pick up the umbilical and lift it up to a mobile tank robot, which will then connect and unload the finished products. In this respect, the surface treatment system looks a lot like a service station here on Earth, but instead of gasoline, it could distribute water. Or liquid oxygen. Or liquid methane. Or all three!

We recently demonstrated this ISRU plant at Swamp Works Lab in Florida. At this point, we had to simulate the oven and electrolyser to reduce costs and complexity. We also simulated the three different finished products using water for all three. But we used prototypes of hardware and software for all the other parts.

By bringing these subsystems together, we have investigated some of the problems and failures, and we have learned a number of important lessons that we would have learned only much later if we had only integrated our system at the end of our development processes. test. This is one of the fundamental principles of Swamp Works: rapid prototyping and early integration, allowing rapid proof of concept and early failures.

The idea of this Mars rocket fuel plant is that it be packaged in a small, orderly box, shipped to Mars, and deployed and commissioned on the surface of Mars well before the explorers arrived. Human missions on Mars will depend on this factory to independently produce and store the fuel needed for their return journey, even before these astronauts leave the Earth. There are also NASA teams looking for ways to grow all kinds of different things during transit and on Mars. Including potatoes.

So what needs to be done here? Well, a lot.

NASA has years of experience with autonomous landers and independent rovers operating on the surface of Mars. And our newest rovers – Curiosity, which landed in 2012, and the March 2020 rover, for launch in 2020 – have some built-in autonomy. But the complexity of this rocket fuel fabrication plant, as well as the long-lasting level of autonomy that will be required for such a system will take things to a whole new level.

Photo: Glen Benson / NASA

In the meantime, many technical challenges must be overcome before a mission of this type can succeed. One of the most critical issues is whether each subsystem of our current Mars surface treatment system can be upgraded to meet the needs and throughput required by a human mission on Mars. Recent studies by NASA estimate that a system of this type will have to produce about 7 tons of liquid methane and about 22 tons of liquid oxygen in about 16 months. Next, we need to determine where to land and dig to optimize our performance, how many RASSOR excavators we will need and how many hours per day will be needed. We must also determine the size of the carbon dioxide freezer and the Sabatier reactor, as well as the power required for all these equipment.

In addition, we must anticipate problems by identifying potential point failures that could interrupt the surface treatment mission and thereby delay the future planned human mission. We will need to evaluate the probabilities of each of these failures in order to add the appropriate amount of duplication and redundancy to the system.

For robotic technologies to be able to support this mission for years without maintenance or repair, we will have to design them to very strict specifications. All moving parts must stay out of these tiny particles of destructive regolith dust. Reinforcing sealing technologies or strengthening moving parts to tolerate dust will add complexity and weight unless we can find an ingenious solution to the problem.

We must also determine the density or hardness of the regolith and ice mixture below the surface of Mars, and then design the digging tools appropriately. The scoops and teeth of our RASSOR excavation robot are best suited for packaged regolith mixed with ice chips. But this design will not be suitable for breaking large sheets of hard and hard ice. We will need definitive evidence of the composition of the ice and the regolith beneath the surface on Mars in order to design the most appropriate and effective digging equipment. Either this, or we will have to design more complex and robust tools capable of managing various soil and ice densities.

And we need to solve the long-term storage problems of super-cold liquids. Technologies and materials for pressure vessels and insulation are constantly improving, but will current technologies work on the surface of Mars for long periods of time?

NASA will examine all these challenges in the coming years. And we will continue to increase the capacity and readiness of all our prototype components. We will make the RASSOR robot stronger and lighter and test it in environments similar to those of Mars. We will continue to test and integrate the furnace and the electrolyser, and we will try to increase the capacity of the carbon dioxide freezer and the Sabatier reactor to verify that they can meet the needs of a Mars crewed mission. All this work and others will continue so that our dust-push prototype can one day become a fully operational system on Mars.

This article appeared in the November 2018 issue under the title "From dust to thrust".

Source link