[ad_1]

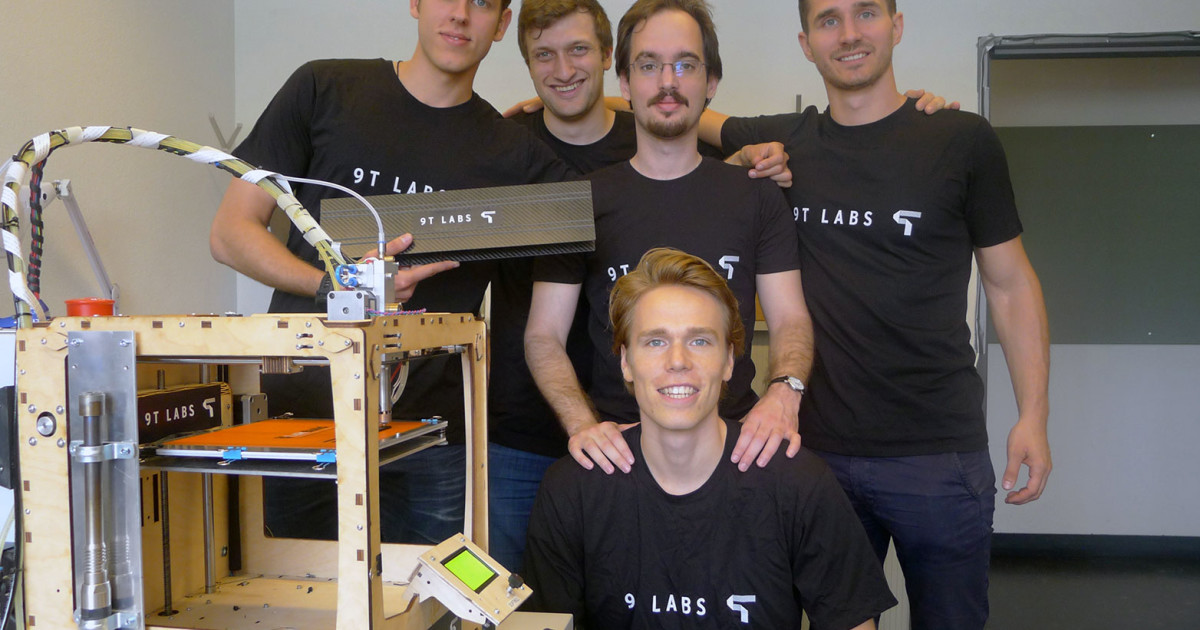

Three ETH graduates developed a 3D printer capable of producing carbon components. With their 9T Labs, the trio could make a breakthrough in the robust composite material.

Firmer than steel but up to five times lighter: Carbon fiber reinforced plastics (CFRP), often called carbon, are perfect to be tough, but still have little weight: planes, Formula 1 racing cars, ATVs, but also robots, prostheses or implants. It is not surprising that carbon is currently in great demand in the global market. The problem is that carbon is expensive compared to aluminum or steel. The reason is the long and expensive production. Carbon is a composite material. In order to produce the durable material, the plastic and carbon fibers must be assembled and processed. In general, each component requires its own negative form. Its production is expensive.

Manufacturing carbon parts without negative molds

The ETH spin-off 9T Labs now offers an alternative: It has developed a 3D printer that delivers carbon parts. These are no longer laboriously made with negative shapes, but on the computer with the help of software designed and produced by the printer. The assembly of plastic and fibers takes place directly in the printer by squeezing the materials through a heated nozzle. "We combine the benefits of 3D printing technology with the benefits of carbon," says Giovanni Cavolina, one of the founders of 9T Labs. On the one hand, this new process can eliminate the biggest current disadvantage of carbon – the high cost – by reducing manufacturing costs and expenses. On the other hand, 3D printing technology makes possible the production of carbon components with a very complex geometry, which is necessary for example in the construction of satellite antennas and others load-optimized structures. Finally, 3D printing reduces the waste of material.

Climbing After Takeoff

Behind 9T Labs are ETH graduates Martin Eichenhofer (30 years old), Giovanni Cavolina (26 years old) and Chester Houwink (25 years old). Eichenhofer had the idea of the start-up four years ago, while he was doing research in the laboratory of composites and adaptive structures with Professor Paolo Ermanni. Normally, the trio began to recover in 2018: in January, he created a public limited company and recruited a total of 300 000 francs from investors. In addition, the start-up has been included in a grant program (ESA BIC Switzerland) by the European Space Agency (see box) which, with 200,000 additional francs, contributes to the creation of a good network in the industry. There are many areas of application and the interest of the industry is great, "says Eichenhofer, who is currently still completing his doctoral dissertation. And Cavolina adds, "It is important for us not to go beyond the market, which is why we want to launch a product as quickly as possible in order to generate feedback."

Source link