[ad_1]

It’s no secret that Tesla’s primary focus revolves around sustainability. Its mission is to accelerate the advent of sustainable energy, which is one of the reasons why every vehicle launched by the company is designed to be a preferable alternative to cars powered by an internal combustion engine. This point became particularly evident recently when the Model Y’s thermal system was compared side-by-side to that of the Ford Mustang Mach-E.

As discussed by automotive dismantling expert Sandy Munro in his Munro Live YouTube channel, the Tesla Model Y’s thermal system is quite a feat in the thought and engineering of first principles. This could be seen in custom designed components such as the Octovalve, as well as in the pipes that Tesla was using for the system. Munro noted that overall, the Model Y’s thermal system only uses 10 pipes with a total length of 6.35 meters, which is very conservative compared to other EVs on the market.

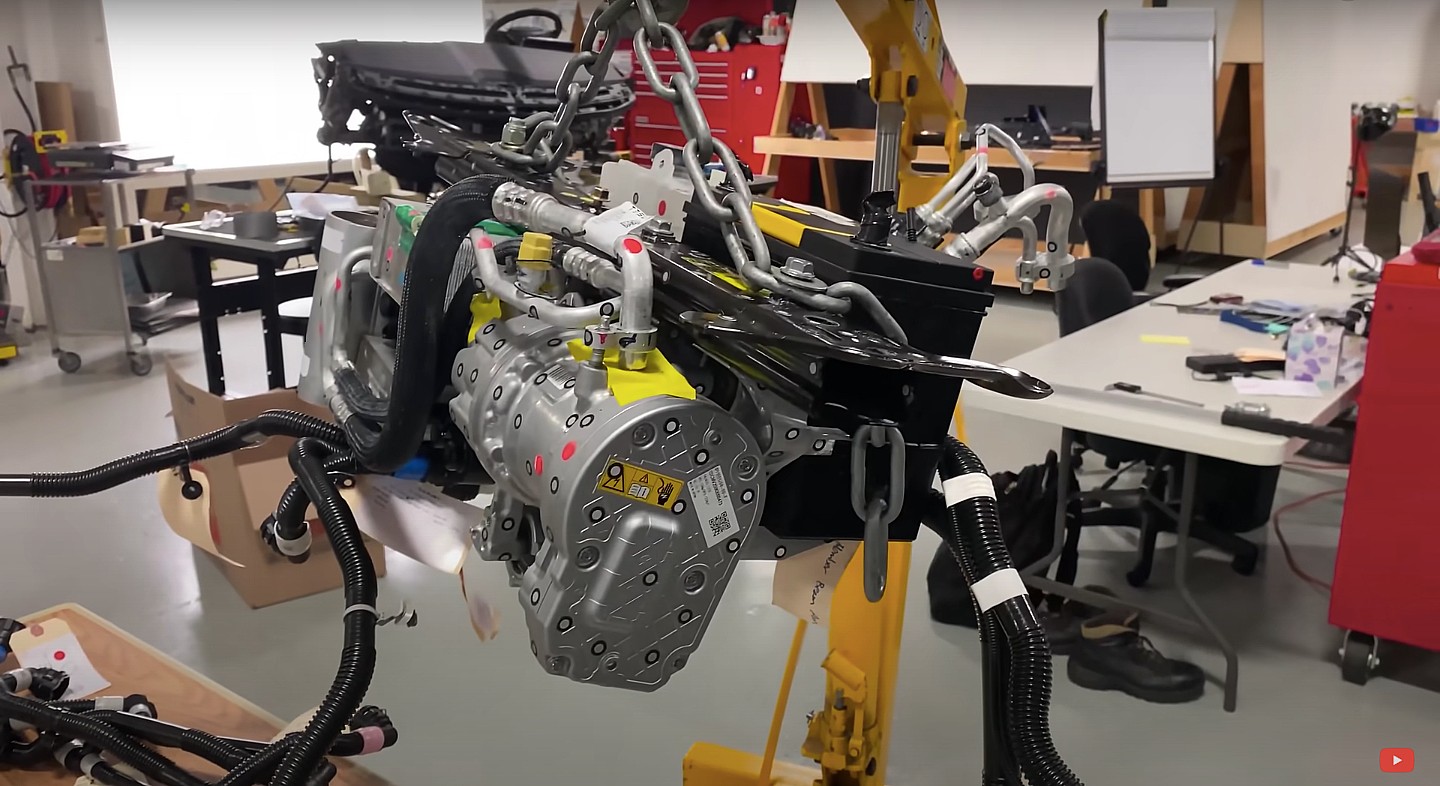

Munro and Associates are currently scrapping the Ford Mustang Mach-E, and one of the things that caught the team’s attention was the all-electric crossover’s thermal system, which the automotive veteran called it of “nightmare”. This “nightmare” was represented by the long, twisted cacophony of pipes that Ford used for the thermal system of its all-electric crossover. Compared to the Model Y, the Mach-E uses 250% more parts, which probably makes the vehicle more expensive to build.

The teardown team found that the Mustang Mach-E’s thermal system had a total number of parts of 35 parts, and the total length of its pipes was 18.42 meters, more than twice that of the hoses used in the Model Y. The fluids in the Model Y are also significantly inferior to those used in the Mustang Mach-E, although they essentially play the same role.

As noted by members of the electric vehicle community familiar with thermal systems, the Mach-E also uses rubber coolant hoses, which are generally heavy and difficult to recycle. These rubber hoses are however very inexpensive despite the fact that they require a lot of energy to manufacture them. In contrast, Tesla appears to use nylon materials for the Model Y tube, which is more recyclable and more energy efficient produce. Nylon tubes are significantly lighter than the rubber hoses used in the Mach-E, but they are several times more expensive.

Munro and Associates only showed a glimpse of the engineering feats displayed by the Tesla team when designing the Model Y, but one thing was immediately evident when the all-electric crossover’s thermal system was compared to the Mach. -E. The Tesla Model Y was created from the ground up to be a vehicle designed for a renewable future, and its components appear to have been selected with sustainability in mind. The more expensive but more durable model Y nylon hoses seem to be part of this strategy.

Tesla’s experience in building electric vehicles is evident in the components of the Model Y. Veterans like Ford, on the other hand, still seem to be learning the ropes. But that is not the most stimulating conclusion of Munro’s comparison of the Model Y thermal system and Mach-E. While the Tesla is miles ahead, Munro pointed out that the Ford Mustang Mach-E is already the better non-Tesla electric car which they have demolished and analyzed to date.

Watch Munro’s comparison of the Tesla Model Y and Ford Mustang Mach-E thermal system below.

Do not hesitate to contact us with new tips. Just send a message to [email protected] to warn us.

[ad_2]

Source link