[ad_1]

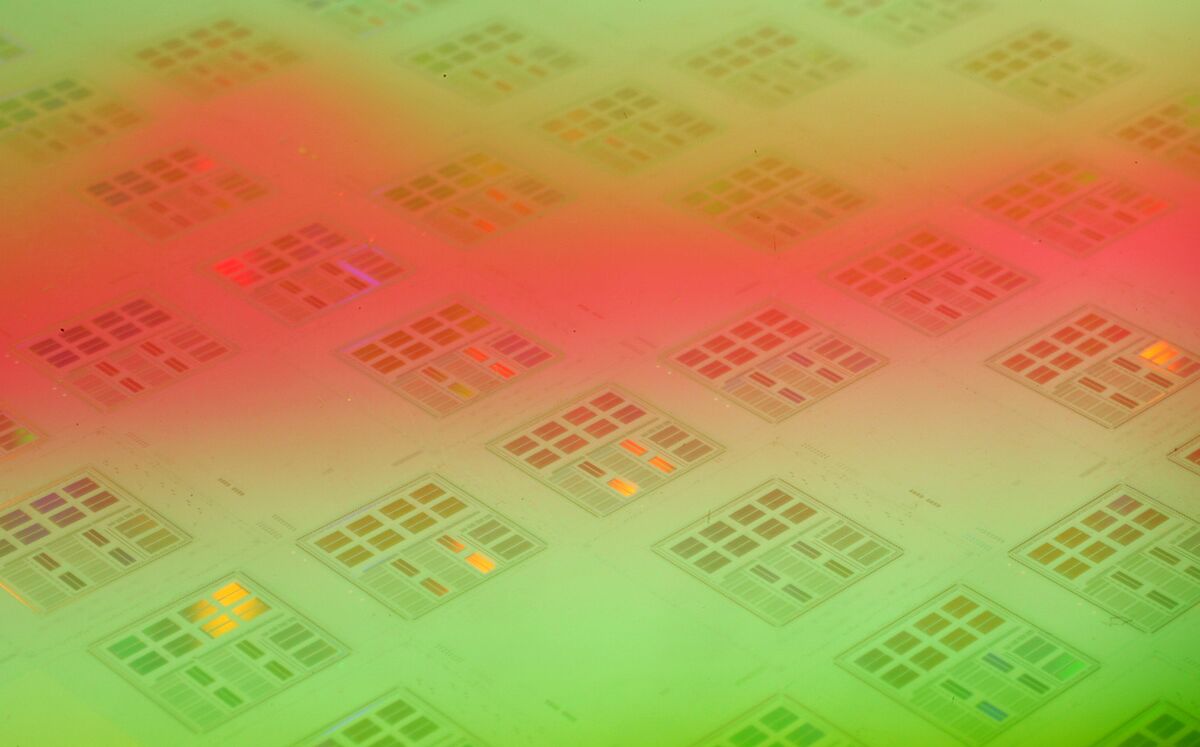

Photographer: Maurice Tsai / Bloomberg

Photographer: Maurice Tsai / Bloomberg

Taiwan Semiconductor Manufacturing Co. plans to spend $ 100 billion over the next three years to expand its chip manufacturing capacity, a staggering financial commitment to meet growing demand for new technologies.

TSMC, the world’s leading manufacturer of advanced semiconductors, has already forecasted a record capital expenditure of as much as $ 28 billion this year, but recent trends and developments have pushed for even more capacity. Now at the center of a global chip supply crisis, Taiwan’s largest company is committed to working with customers across industries to weather a deluge of demand.

Read more: See how a chip shortage destroyed everything from phones to cars

“TSMC plans to invest $ 100 billion over the next three years to increase its ability to support the manufacturing and R&D of advanced semiconductor technologies,” the company said in a statement responding to media reports. “TSMC works closely with our customers to meet their needs in a sustainable manner.”

TSMC providers have jumped in the news, with Tokyo Electron Ltd. up 4.2% and Screen Holdings Co. up 6.3%. TSMC’s share price rose 2% on the day.

Recognized by everyone from Apple Inc. and Qualcomm Inc. at Nvidia Corp. and Advanced Micro Devices Inc., TSMC is the world’s premier semiconductor foundry, or producer of chips designed by others. The silicon it produces goes into virtually every modern electronic device, from smartphones and smart refrigerators to connected cars.

In a letter to customers obtained by Bloomberg News, TSMC CEO CC Wei wrote that the company’s factories were “running at over 100% utilization in the past 12 months,” but demand was still exceeding the offer. Thousands of new employees are being hired and several new factories are under construction, he added, and TSMC will suspend wafer price cuts for a year from early 2022.

Automakers have been hit particularly hard by the chip shortage, with estimated revenue losses of more than $ 60 billion this year. Ford Motor Co. has just said it will temporarily halt production at two factories that make it its bestseller Pickup F-150. F-Series Trucks Are Ford’s Largest creators of money and any loss of production has a direct impact on the bottom line.

| Expenses envisaged | When what | |

|---|---|---|

| TSMC | $ 100 billion | More than three years to increase capacity |

| Intel | $ 20 billion | To build two new factories in Arizona |

| Samsung | 116 billion dollars | More than a decade to develop the foundry activity |

Read more: Samsung warns of severe chip cracking when delaying key phone

American rival Intel Corp. in March announced plans to compete directly with TSMC in manufacturing chips for other companies, with a $ 20 billion investment in two new plants in Arizona. South Korea Samsung Electronics Co. is also spending more than $ 100 billion over a decade to expand its semiconductor business.

– With the help of Keith Naughton

(Updates with the CEO’s letter in the sixth paragraph)

[ad_2]

Source link