[ad_1]

The European Space Agency (ESA) has made further progress in its quest for 3D printing in space using in situ materials.

In partnership with the Austrian specialist in 3D ceramic printing, Lithoz, ESA has demonstrated its ability to produce extremely detailed spare parts, such as screws and gears, from scratch. a lunar regolith simulator.

Advenit Makaya, an advanced manufacturing engineer at ESA for materials and processes, explains to the 3D printing industry what this latest development means for the wider pursuit of the low-gravity manufacturing agency.

A small step for 3D printers …

As discussed in a previous interview with Mr Makaya, ESA is currently at the heart of an In Situ Resource Utilization Project (ISRU), which involves studying different methods of conducting research. 3D printing using native materials from space, such as the Lunar and Martian regoliths. as a sustainable raw material. ESA aims to reduce the high cost of sending consumables into space; make exploration as deep as possible; and prepare astronauts to produce everything they need on stations like the ISS.

Starting small, the agency has already managed to 3D print miniature home concept models using extrusion – based technology.

With Lithoz, ESA has now added lithography-based ceramics (LCM) manufacturing to its regolith manufacturing portfolio. The work was undertaken for a particular activity entitled "Designing a Lunar Base Using 3D Printing Technologies" from the ESA-supported URBAN consortium including COMEX, LIQUIFER Systems Group, SONACA Space GmbH and OHB System AG.

"We are therefore interested in mapping and understanding the use of a wide range of additive technologies, in order to process the manufacturing of all possible items needed at a lunar base, at all scales," says the Dr. Makaya, "from the construction infrastructure, to tooling, furniture, clothing and even food. "

The challenges of the Gross Regolite

The main challenge of the Lithoz / ESA Lunar Base collaboration was to prove that Lithoz's LCM 3D printing technology was working with a raw regolith simulating material, rather than other conventional ceramics already proven. "The regolith simulant was processed by grinding and sieving it to the appropriate particle size, but the simulant composition and mineralogy were left as is",

"This means that the raw material does not have a specific composition (that is, it does not consist of a specific type of oxide or nitride), like the ceramics that Lithoz is used to processing and for which they have an established "recipe." The regolith simulator consists of a mixture of various minerals.

The unusual mix of regolith simulant made the tuning process even more complicated. Mr. Makaya added, "The challenge was to achieve the same level of density and accuracy for this" raw "regolith, compared to what Lithoz can achieve with" conventional "ceramics.

Ceramic makes critical pieces

The samples of parts manufactured with the help of Lithoz LCM are currently worth no more than 5 cents and consist of screws, nuts and bolts that the space team could use to fix parts and build new devices. Accordingly, these ceramic fasteners are ideally suited for applications in which the parts have to withstand very high temperatures, high pressures, corrosive or abrasive environments, or where they must be electrically nonconductive or non-magnetic. . requirements that metals can not easily cope with, "

"In the context of the lunar base, the main engine for producing ceramic parts. is the great abundance of regolithic material. All additive manufacturing technologies will not be suitable for all uses. But sintered ceramic parts with high precision and complex shapes – that is, the type of parts that 3D regolith printing can produce – have a role to play in the overall maintenance strategy. […]"

In order to produce the pieces, the regolith powder had to be combined with a light reactive binder. After printing, the pieces were then sintered to produce a solid solid.

"The particular technology of lithographic ceramics manufacturing, thanks to its ability to produce very fine details on regolithic objects, seems very well adapted to the manufacture of elements requiring a high precision and a good dimensional accuracy", Dr. Makaya concludes.

"Having a way to locally manufacture spare parts, using the abundant regolith resource seems very attractive, compared to the need to get these pieces on Earth. We are talking about very small items, but potentially having a critical function if they are part of a key equipment or instrument. "

3D printers in the space

At the present time, tank polymerization techniques do not yet permit 3D printing in low gravity conditions, although the potential of the project may justify the development of such systems at low temperatures. to come up.

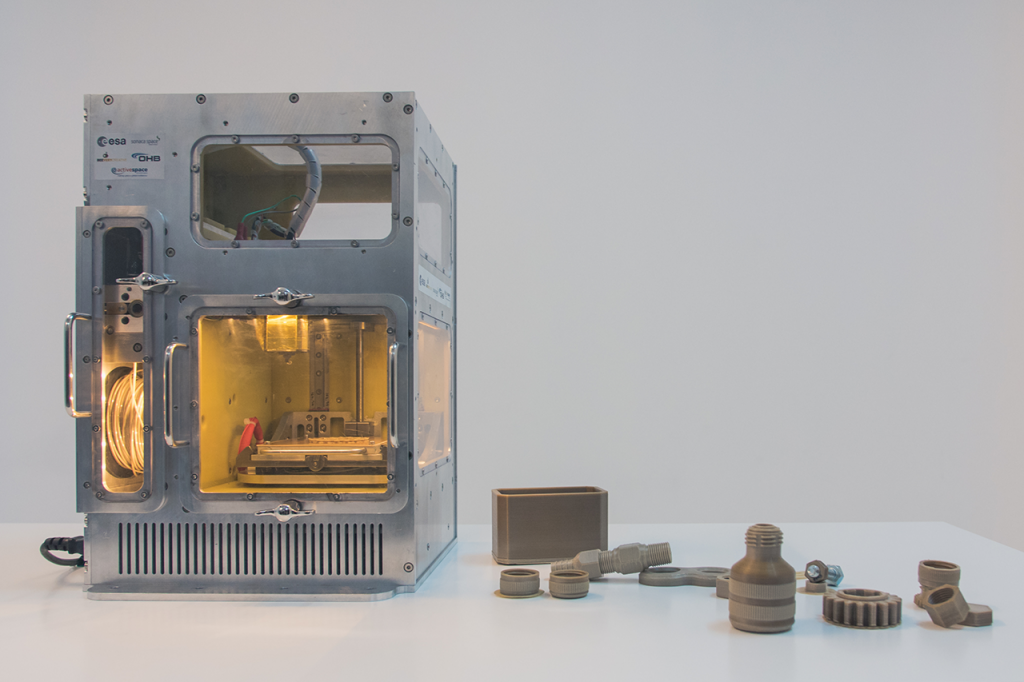

Until now, the American Made In Space microgravity manufacturing specialist has installed the FFF-based additive manufacturing system (AMF) aboard the ISS and has managed to produce small tools and components.

Then, as part of the MELT project, ESA plans to place a high-temperature FFF 3D printer on board the station for testing, and Made In Space has been authorized to develop a metal system for microgravity conditions.

For exclusive interviews and news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Join 3D Printing Jobs now to find the next step in your academic career.

The picture shown shows Dr. Advenit Makaya, Advanced Manufacturing Engineer at ESA, Materials and Processes. Picture of Clara Cruz / ESA

[ad_2]

Source link