[ad_1]

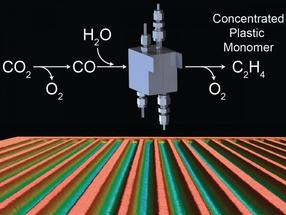

This illustration is an artistic interpretation of the electrolysis process used to convert CO2 to concentrated carbon products.

Scientists at Stanford University have developed electrochemical cells that convert carbon monoxide (CO) derived from CO2 in commercially viable compounds more efficiently than existing technologies. Their research provides a new strategy for capturing CO2 and convert it into chemical raw materials.

CO2 capturing from emission sources is an attractive option to mitigate climate change, but it is an expensive process to harvest a product with no commercial value. However, scientists can add value to captured CO2 using electrolysis, a technique that uses an electric current to break down compounds, to convert it into more desirable products such as ethylene for the production of polymers or acetate as a reagent for chemical synthesis.

"C2 products such as ethylene, acetate and ethanol have intrinsically more value than C1 products such as methane, as they constitute a versatile chemical raw material," states Dr. Lead author Matthew Kanan, associate professor of chemistry at Stanford University.

When converting CO2 CO is already commercially feasible, the development of a technology to produce C2 chemicals sought from CO on an industrial scale remains a challenge. To be viable, electrolysis must convert CO into products at a high rate with low overall energy demand. Older electrochemical cells needed a large excess of CO to reach a high electrolysis rate, which gave diluted products that needed to be concentrated and purified – a process requiring more energy (at higher cost).

The electrochemical cells created by Kanan and his team combat these inefficiencies with a modified design that produces a concentrated flow of ethylene gas and a sodium acetate solution 1000 times more concentrated than the product obtained with previous cells. The cell utilizes a gas diffusion electrode (GDE) combined with a carefully designed flow field, which greatly improves the supply of CO to the electrode surface and the elimination of the products. . The team also eliminated the need for an electrolyte solution in the cell by interfacing the GDE directly with a membrane. As a result, ethylene and a concentrated acetate solution are produced at the electrode and exit the cell in a single stream of steam.

"Prior to this work, the combination of a high electrolysis rate, a high conversion of CO and concentrated product streams had not been achieved," says Kanan.

The team is currently working on extending its prototype to determine if the design needs to be modified to succeed on an industrial scale, in the hope of being able to combine its CO electrolysis cells with existing CO.2 The device can also be useful for space exploration, especially for deep space missions where it is not possible to replenish from Earth. In collaboration with researchers led by John Hogan of NASA's Ames Research Center, the team is working to combine electrochemical synthesis with microbial biosynthesis to recycle CO.2 expired by astronauts in food and nutrients.

Source link