[ad_1]

Made In Space California Pioneers 3D out-of-world printers plan to use 3D printing to turn asteroids into autonomous space vessels that could potentially fly to Mining Stations

This plan is part of the Reconstructing Asteroids in Mechanical Automata (RAMA) project, which is funded by NASA's Innovative Advanced Concepts (NIAC) program . Thanks to the RAMA project, Made In Space aims to allow the colonization of space with an efficient and economically viable out-of-the-world manufacturing, that is, 3D microgravity printers.

The Asteroid Spacecraft

The concept of autonomous asteroid spacecraft derives from the fact that astronauts become less dependent on terrestrial resources and instead use new and extraterrestrial materials for help. In a recent article James Dunn, co-founder and director of Made In Space said:

"We have the ability to bring Earth's resources, but when we come to a point of tipping where we need Resources in the space, then the question becomes, "Where do they come from and how do we get them, and how do we deliver them to the place where we Do we need it? "It's a way to do it."

Regolith, the layer of dust and soil of the material covering the rocks found on Earth, Mars and the Moon has already been proposed to be used in off-world construction This is due to the fact that it is a resource of chemical elements and compounds, such as metals and minerals, necessary to support the manufacture of parts or to construct structures on planetary surfaces.

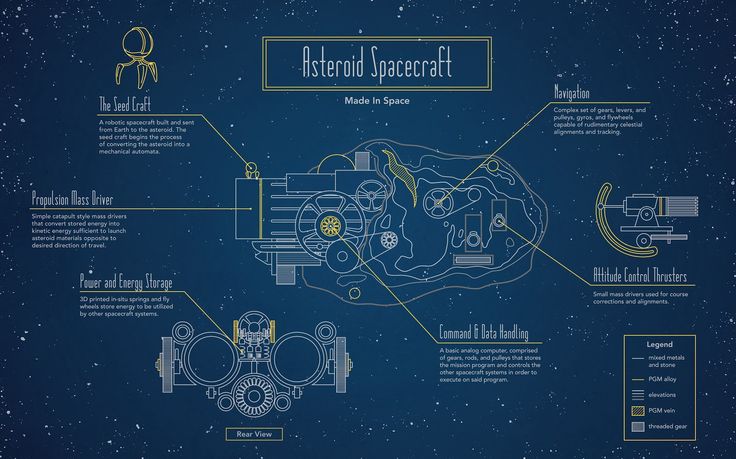

Recital cec i, Made In Space will use a robotic Seed Craft "to harvest material from space rocks and use it as a raw material for propulsion construction, navigation, energy storage and other systems on-site keys as well as 3D printing and other technologies.

Thus, the conversion of near-Earth asteroids into autonomous vessels can potentially be programmed to fly to a mining station in Earth or Space, for collect more resources for astronauts in need.

This plan outperforms previous methods that included launching capture probes on individual space rocks for exploration. Nevertheless, the asteroid spacecraft will not have rocket engines or complex electronic circuits found on traditional spacecraft; rather, its construction would be simple and mechanical.

"The RAMA project is not starting from scratch, autonomous 3D printers using mechanical systems already exist, just like mechanical computers in 3D printed parts," adds Dunn

The NIAC program will provide $ 100,000 for Feasibility studies such as Made In Space plans to complete and successfully execute an asteroid spacecraft by 2030.

Pioneer of Above Ground Manufacture

Made in Space has gained a notoriety in the past. to be the first to put 3D printers on the International Space Station (ISS) 3D Printing Industry also interviewed Made In Space on its brand new system Archinaut – a set of technologies enabling orbital manufacturing

In addition, in 2017, Made In Space was awarded a NASA ] Small Business Innovation Research Contract (SBIR) to develop it oppment of its Vulcan hybrid manufacturing system .

According to Dunn, Made In Space is now counting on NASA to advance in situ resource utilization technology (ISRU) – the ability to live on some land – to advance the RAMA project.

Stay up-to-date with the latest news in 3D printing by subscribing to bulletin 3D Printing Industry . Also, follow us on Twitter and as we on Facebook .

Looking for a change of pace or looking for new talent? Search and Publish 3D Print Jobs for opportunities and new talents in engineering, marketing, sales and more.

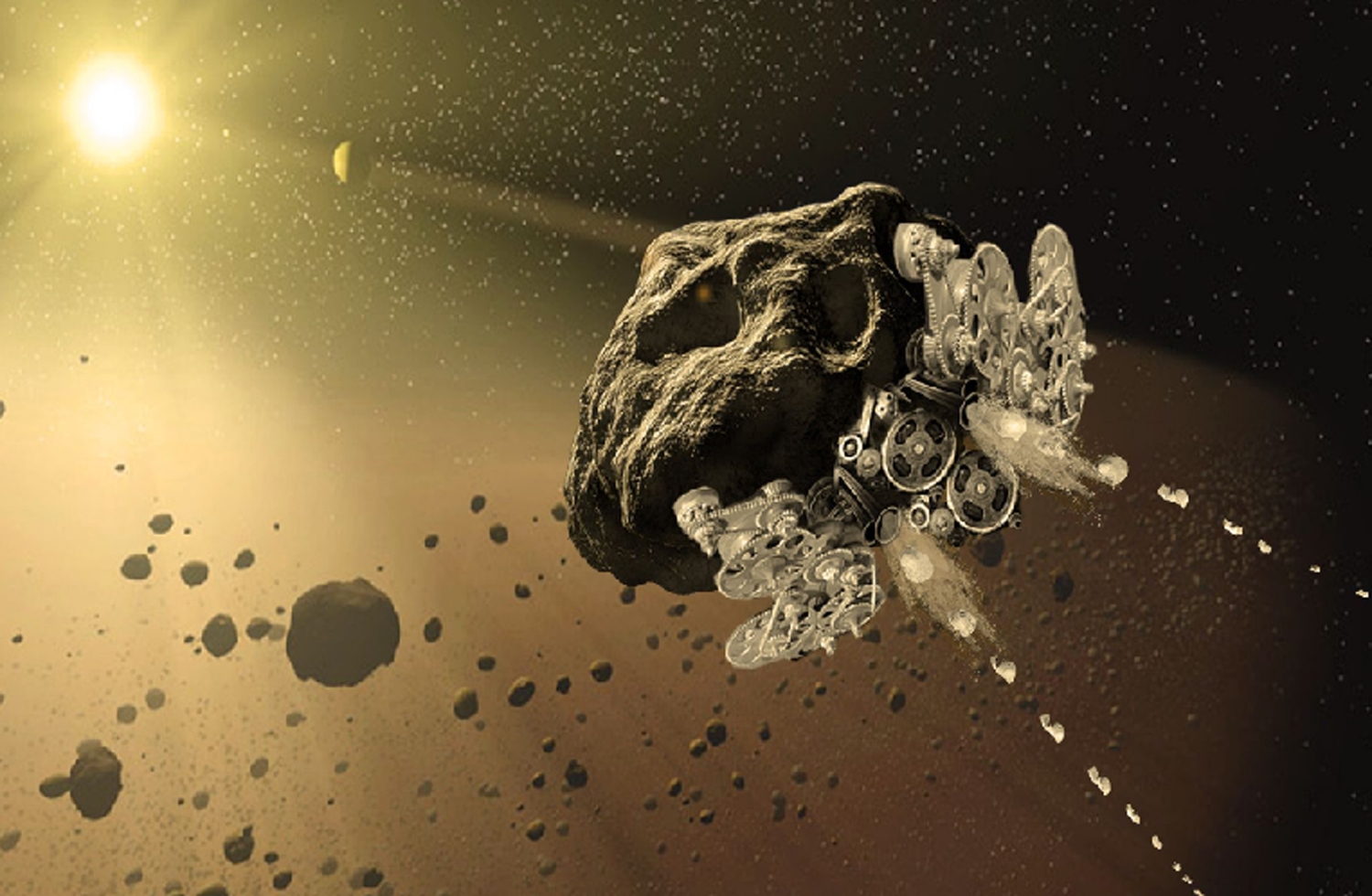

The featured image shows an illustration of the asteroid spacecraft. Image via Made In Space.

[ad_2]

Source link