[ad_1]

Because of the high costs and risks associated with space travel, NASA engineers tend not to be limited to what works. It means using proven materials like titanium and aluminum. But traditional designs and materials are often heavy – and in an area where every gram counts, losing a little weight means adding more sensors and instruments. To push landing designers into new directions, Autodesk is turning to its machine learning technology to iterate faster than it could otherwise.

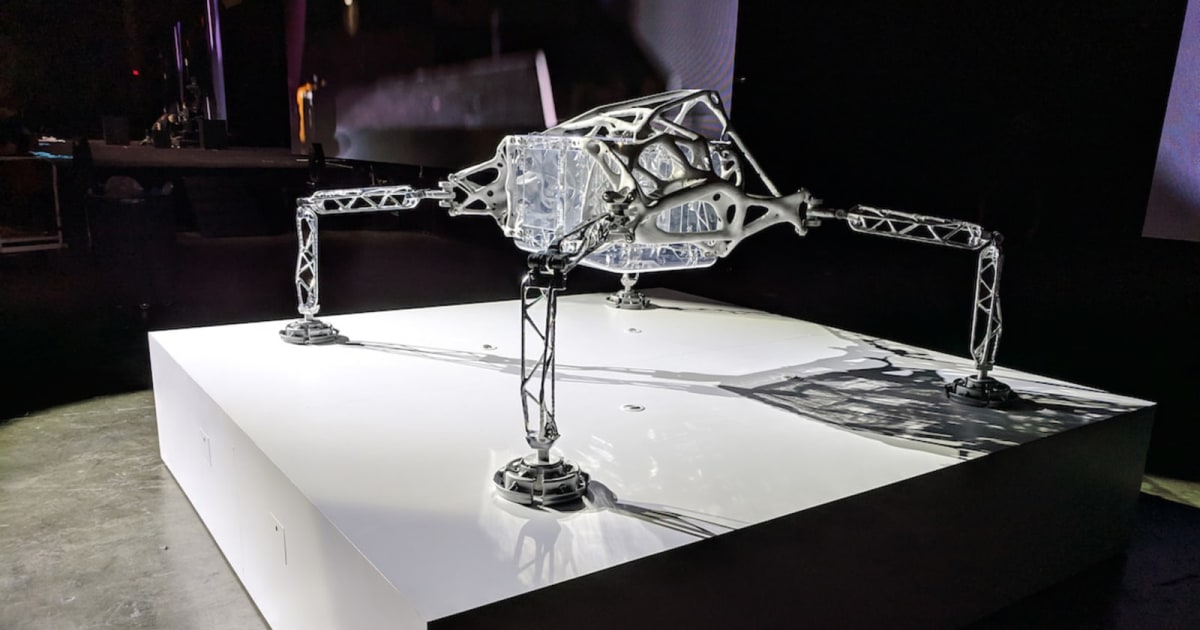

Autodesk calls this new process "generative design" or design that uses artificial intelligence and cloud computing that creates a wide range of solutions based on limitations defined by engineers. Autodesk used this system, available on its Fusion 360 software, in Formula One racing. According to Autodesk, generative design allows engineers to develop design solutions in less than two to four weeks, much faster than both. at four months standard. Autodesk hopes that its design technology will help JPL place a landing gear on the moons of Jupiter or Saturn, paving the way for settlements. (If this happens in our lifetime is another question.)

This does not mean that it would be the first time humans have explored Jupiter or Saturn. In October 1997, NASA, together with the European Space Agency (ESA) and the Italian Space Agency (ASI), launched the Cassini-Huygens spacecraft to study Saturn. It took six years and 261 days for the probe to reach the ringed planet, but the photos she sent back were remarkable. It is September 15, 2017 that NASA had a contact with Cassini for the last time. And currently, the Juno probe is in orbit around Jupiter and has allowed us to better understand what is happening in the gas giant. To reach the moons of Saturn and Jupiter, respectively at 365 and 746 million miles depending on their orbit, it will always be difficult to make progress, but any breakthrough that NASA could achieve would be welcome if it allowed a potential of our solar system.

Source link