[ad_1]

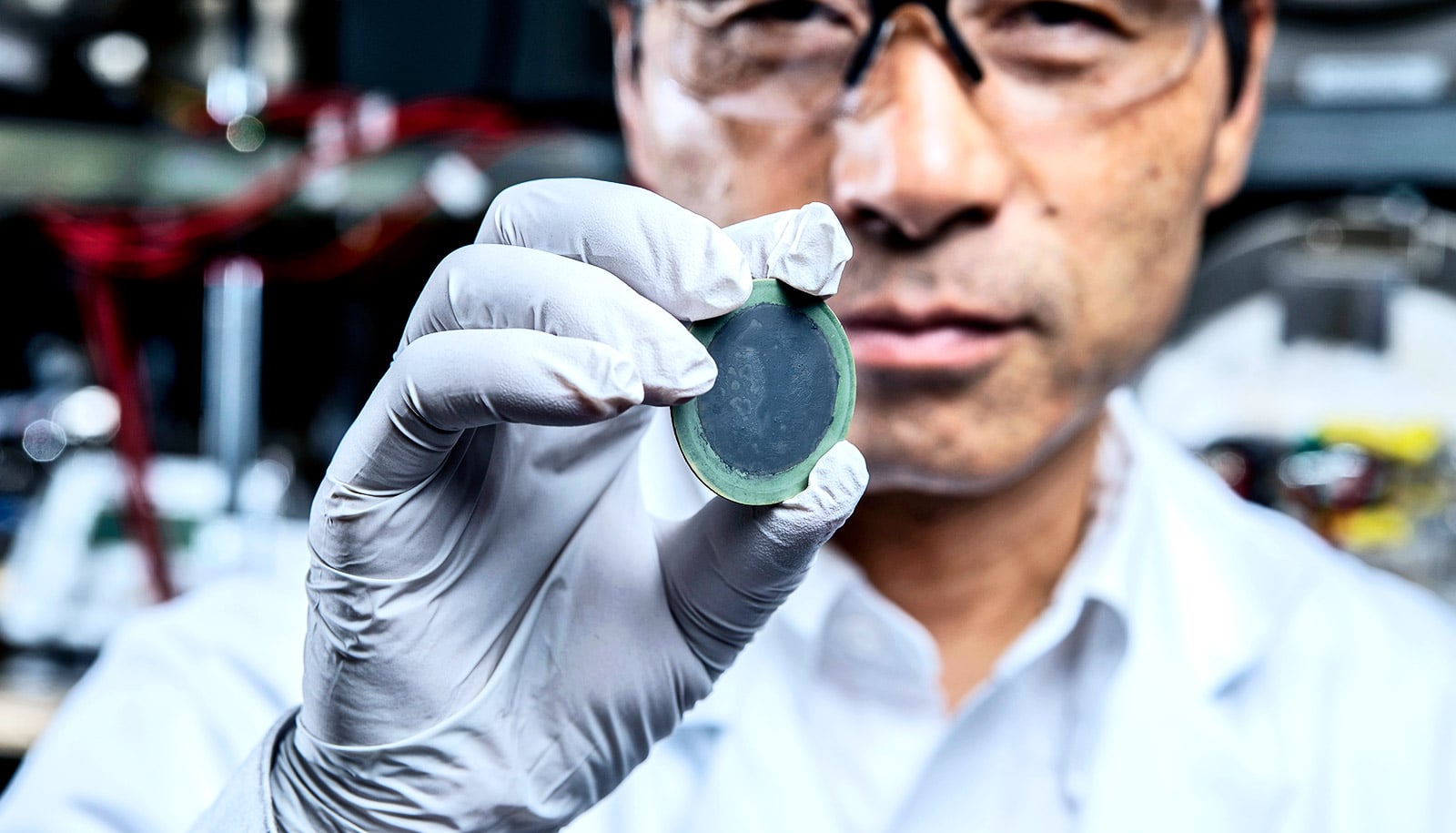

Researchers have created a new fuel cell that runs on cheap fuel at temperatures comparable to automobile engines and could slash materials costs.

Fuel cells have not been particularly known for their practicality and affordability, but that may have just changed. Though the cell is in the lab, it has high potential to someday electrically power homes and perhaps cars, the researchers say.

In a new study in the journal Nature Energy, the researchers detailed how they reimagined the entire fuel cell with the help of a newly-invented fuel catalyst.

The catalyst has dispensed with high-priced hydrogen fuel by making its own out of cheap, readily available methane. And improvements throughout the cell cooled the seething operating temperatures that are customary in methane fuel cells dramatically.

Methane fuel cells usually require temperatures of 750 to 1,000 degrees Celsius to run. This new one needs only about 500, which is even a notch cooler than automobile combustion engines, which run at around 600 degrees Celsius.

That lower temperature could trigger cascading cost savings in the ancillary technology needed to operate a fuel cell, potentially pushing the new cell to commercial viability. The researchers feel confident that engineers can design electric power units around this fuel cell with reasonable effort, something that has eluded previous methane fuel cells.

Sensational cell

“Our cell could make for a straightforward, robust overall system that uses cheap stainless steel to make interconnectors,” says study leader Meilin Liu, a professor in the School of Materials Science and Engineering at Georgia Tech. Interconnectors are parts that help bring together many fuel cells into a stack, or functional unit.

“Above 750 degrees Celsius, no metal would withstand the temperature without oxidation, so you’d have a lot of trouble getting materials, and they would be extremely expensive and fragile, and contaminate the cell,” Liu says.

“Lowering the temperature to 500 degrees Celsius is a sensation in our world. Very few people have even tried it,” says Ben deGlee, a graduate research assistant in Liu’s lab and one of the first authors of the study. “When you get that low, it makes the job of the engineer designing the stack and connected technologies much easier.”

The new cell also eliminates the need for a major ancillary device called a steam reformer, which is normally required to convert methane and water into hydrogen fuel.

More power independence

The researchers based their work on a type of fuel cell with high potential for commercial viability, the solid oxide fuel cell (SOFC). SOFCs are known for their versatility in fuels they can use.

If it goes to market, though, the new cell might not power automobiles for a while, it could land sooner in basements as part of a more decentralized, cleaner, cheaper electrical power grid. The fuel cell stack itself would be about the size of a shoebox, plus ancillary technology to make it run.

“The hope is you could install this device like a tankless water heater. It would run off of natural gas to power your house,” Liu says. “That would save society and industry the enormous cost of new power plants and large electrical grid expansions.”

“It would make homes and businesses more power independent. That kind of system would be called distributed generation, and our sponsors want to develop that.”

Making electricity for less

Hydrogen is the best fuel for powering fuel cells, but its cost is exorbitant. The researchers figured out how to convert methane to hydrogen in the fuel cell itself via the new catalyst, which is made with cerium, nickel, and ruthenium and has the chemical formula Ce0.9Ni0.05Ru0.05O2, abbreviated CNR.

When methane and water molecules come into contact with the catalyst and heat, nickel chemically cleaves the methane molecule. Ruthenium does the same with water. The resulting parts come back together as that very desirable hydrogen (H2) and carbon monoxide (CO), which the researchers surprisingly put to good use.

“CO causes performance problems in most fuel cells, but here, we’re using it as a fuel,” Chen says.

H2 and CO continue on to further catalyst layers that make up the anode, the part of the fuel cell that yanks off electrons, making the carbon monoxide and hydrogen positively charged ions. The electrons travel via a wire—creating the electricity flow—toward the cathode.

There, oxygen, which is very electron-hungry, sucks up the electrons, closing the electrical circuit and becoming O2-ions. Ionized hydrogen and oxygen meet and exit the system as water condensation; the carbon monoxide and oxygen ions meet to become pure carbon dioxide, which could be captured.

For the energy produced, fuel cell technology creates far, far less carbon dioxide than combustion engines.

In some fuel cells, the water in the initial reactions must be introduced from the outside. In this new fuel cell, it’s replenished in the last reaction phase, which forms water that cycles back to react with the methane.

Faster, stronger

The new catalyst, CNR, which research collaborators at the University of Kansas manufactured, is the outer layer of the anode side of the cell and doubles as a protectant against decay, extending the life of the cell. CNR has strong cohort catalysts in inner layers and on the other side of the cell, the cathode.

On the cathode end, oxygen’s reaction and movement through the system are usually notoriously slow, but Liu’s lab has recently sped it up to raise the electricity output by using what’s called nanofiber cathodes, which Liu’s lab developed in a prior study. (A tailored double perovskite nanofiber catalyst enables ultrafast oxygen evolution.)

“The structures of these various catalysts, as well as the nanofiber cathodes, all together allowed us to drop the operating temperature,” Chen says.

The Office of Basic Energy Sciences and the Advanced Research Projects Agency-Energy (ARPA-E), both in the US Department of Energy, funded the research. The National Science Foundation’s Division of Chemistry also provided funding.

Additional researchers from Georgia Tech, the University of Kansas, and the Queen’s University of Belfast contributed to the work. Any results, conclusions, and opinions are those of the authors and not necessarily of the funding agencies

Source: Georgia Tech

Source link