[ad_1]

Mars lacks the immense natural resources we now rely on, and astronauts who attempt to colonize or even visit the Red Planet can only carry a limited amount of material. Learning to do with what Mars has to offer is one of the biggest challenges of visiting our closest neighbor, but the results of the latest 3D printing experiments from the European Space Agency prove that it is not impossible.

We sent probes and rovers on Mars, but to date, it was a one-way trip. Our knowledge of making Mars is limited to what the Spirit and Opportunities can learn from samples and the study of Martian meteorites that have traveled to Earth. Like our moon, if something does not fail in Mars, it's dust. The researchers turned to a simulated version of the lunar soil, also known as the lunar regolith.

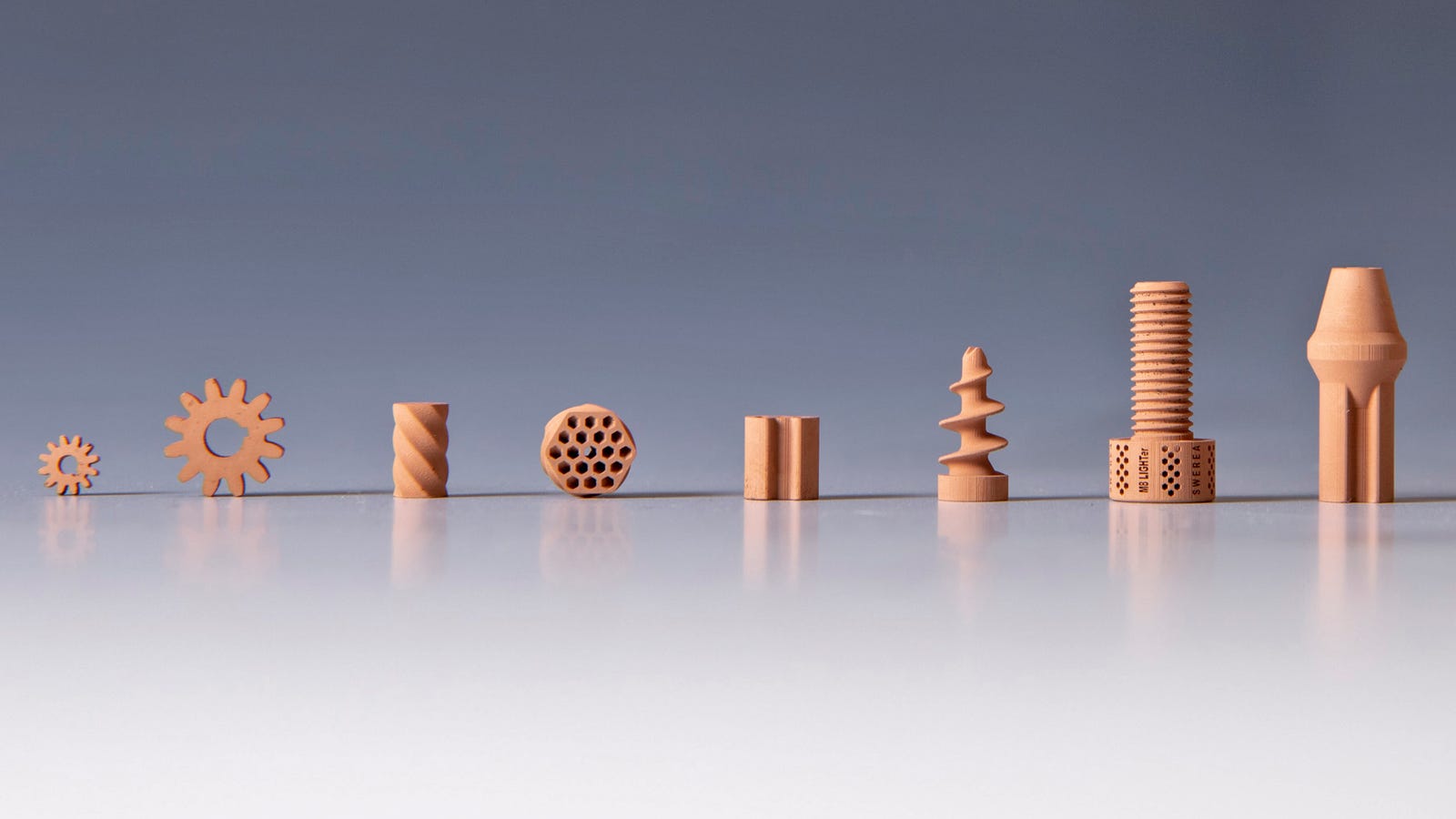

In collaboration with an Australian company called Lithoz, ESA has 3D printed a sample of different pieces using a photosensitive binder mixed with regolith, itself consisting of oxides of silicon, aluminum, calcium and iron that have been crushed. very fine dust. Instead of heating the mixture and allowing it to cool and harden, it is extruded like hot glue, but the 3D printing technique used here consists of very thin layers of the mixture of regoliths, which are exposed to light, causing the solidification of the binder. .

The pieces are then baked to create a solid ceramic material, not only solid, but also smooth and homogeneous, making them compatible with machined parts created with great precision. If you've ever held a 3D printed plastic object, the obvious imperfections on its surface are easy to spot and problematic for use in precision machinery.

ESA's next step is to thoroughly test the strength and durability of these 3D printed parts to determine if they can withstand the rigors of space travel and life in a hostile environment. Finally, instead of pulling a trailer filled with spare parts, a human mission on Mars should simply carry a digital archive of all the parts used in the ship and other structures, a 3D printer and perhaps a bucket to collect local data. ground.

[European Space Agency via designboom]Source link