[ad_1]

Scientists have developed a type of lightweight foam made of hollow metal spheres that can withstand the impressive impact of .50 caliber cartridges: types of bullets fired by heavy machine guns and sniper rifles.

This specially designed material, called Metal Composite Foam (CMF), weighs only half as much as conventional steel armor and is just as effective in protecting against these deadly projectiles, even when tested against tests. resistance to shielding.

"The CMF armor weighed less than half of the homogeneous rolled steel armor needed to achieve the same level of protection," said Afsaneh Rabiei, an engineer and materials specialist, from the University of North Carolina ( NCSU).

"In other words, we have been able to achieve significant weight savings – which benefit vehicle performance and fuel consumption – without sacrificing protection."

Rabiei was involved in the development of composite metal foam at NCSU about 15 years ago. Today, she heads the University's Advanced Materials Research Laboratory (AMRL).

In the lab, his team spends a lot of time experimenting to try to understand what this metal foam is capable of.

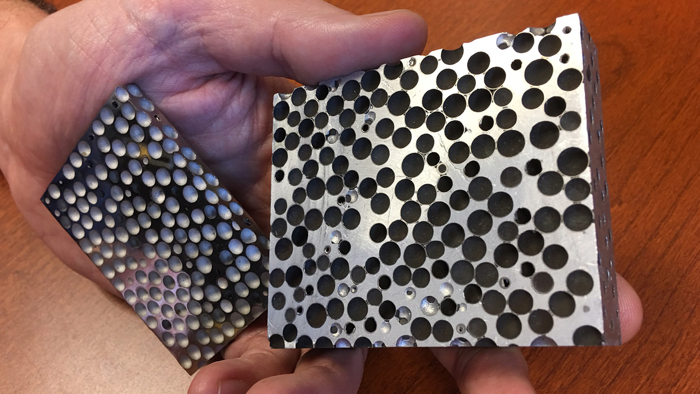

The CMF, manufactured according to patented processes, is made from metals, including aluminum and steel, which are riddled with hollow air pockets, as well as other types of foams. .

In previous research, Rabiei's team has shown that CMF can suppress medium-sized bullets, protected against the firing of highly explosive explosives, in addition to protection against fire, heat and various types of radiation and radiation.

In the new work, the researchers wanted to see how the CMF would cope with the lethal force of .50 caliber cartridges measuring 12.7 x 99 mm – among the largest kinds of bullets commonly used in conventional machine guns and long rifles. scope.

Their experiments involved launching .50 caliber bullets and shells at CMF at speeds ranging from 500 meters per second to 885 meters per second.

During testing, the CMF served as the active core in the shield, covered with a ceramic front plate, with a thin aluminum backplate.

(State University of North Carolina)

(State University of North Carolina)

The results showed that the CMF layer could absorb 72 to 75% of the kinetic energy of the bullets and 68 to 78% of the kinetic energy of the piercing ammunition and prevented the penetration of the projectiles at a speed of up to 819 meters. second. second.

Although the researchers say that there is still room to optimize the material, it is amazing to think that this engineered foam filled with air pockets can stop the projectiles moving to more than 800 meters per second.

"We could do extra work to further improve the situation," Rabiei said.

"For example, we want to optimize the adhesion and thickness of ceramic, CMF and aluminum layers, which could further reduce the total weight and improve the effectiveness of the final shielding . "

Even in its current form, we are considering some sort of material designed to stop some of the most deadly bullets used in wartime – and for a material weighing up to half the standard protection, which means that vehicles military could be lighter. and more manageable.

It is clear that such material benefits are absolutely necessary – provided that the weapon manufacturers continue to manufacture bullets.

The results are reported in Composite structures.

[ad_2]

Source link