[ad_1]

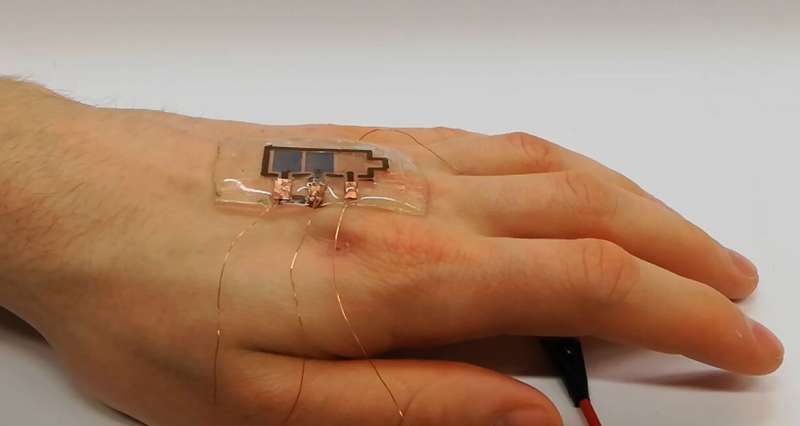

Thanks to its flexibility and grip, the biodegradable screen can be worn directly on the hand. Credit: Manuel Pietsch, KIT

Over the next few years, the increasing use of electronic devices in consumables and new technologies for the Internet of Things will increase the amount of electronic waste. To save resources and minimize waste volumes, greener production and a more sustainable life cycle will be needed. Scientists at the Karlsruhe Institute of Technology (KIT) were the first to produce screens whose biodegradability has been verified and certified by an independent office. The results are reported in the Materials Chemistry Journal.

“For the first time, we have demonstrated that it is possible to produce sustainable screens largely based on natural materials using industrially relevant production methods. After use, these screens are not electronic waste, but can be composted. In combination with recycling and reuse, this could help minimize or completely prevent some of the environmental impacts of electronic scrap, ”says Manuel Pietsch, lead author of the publication and researcher from KIT’s Light Technology Institute (LTI), who works at the Heidelberg InnovationLab.

Low power consumption, simple component architecture

The operation of the display is based on the so-called electrochromic effect of the initial organic material. When a voltage is applied, the absorption of light is changed and the material changes color. Electrochromic displays have low power consumption and simple component architecture compared to commercially available displays, such as LEDs, LCDs, and electronic paper. Another advantage is that these screens can be produced by inkjet printing in a personalized, inexpensive and material-saving manner. In addition, this process is suitable for scaling with high throughput. The materials mainly used are of natural or biocompatible origin. Sealing with gelatin makes the screen adhesive and flexible, so that it can be worn directly on the skin.

Use in medical diagnostics and food packaging

The display is generally suitable for short life cycle applications in various industries. In medical diagnostics, for example, where hygiene plays an important role, sensors and their indicators should be cleaned or disposed of after use. The newly developed screen will not be thrown away as electronic scrap, but is compostable. It can also be used for quality control of food packaging, where reuse is not allowed. Digital printing allows screens to be adapted to people or complex shapes without costly changes to the process. This reduces the consumption of resources.

“As far as we know, this is the first demonstration of a biodegradable screen produced by inkjet printing. It will pave the way for sustainable innovations for other electronic components and electronics production. greener, “says Gerardo Hernandez-Sosa, Head of LTI’s Printed Electronics Group at the Heidelberg InnovationLab.

Have an eye for colors: printable light sensors

Manuel Pietsch et al. Biodegradable inkjet printed electrochromic screen for durable electronics with short life cycle, Journal of Materials Chemistry C (2020). DOI: 10.1039 / d0tc04627b

Provided by Karlsruhe Institute of Technology

Quote: Researchers develop biodegradable printed screen (2021, January 26) retrieved January 27, 2021 from https://phys.org/news/2021-01-biodegradable.html

This document is subject to copyright. Apart from any fair use for study or private research, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link