[ad_1]

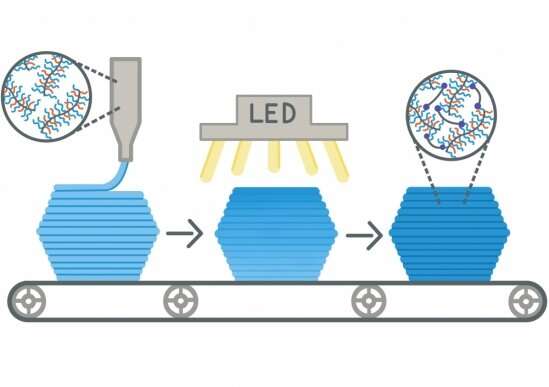

Left to right: Unbound polymer ink, infrared light applied to activate crosslinks, and the end product – a super soft, super elastic crosslinked elastomer. Credits: Isabelle Chabinyc

Researchers from the laboratories of Christopher Bates, assistant professor of materials at UC Santa Barbara, and Michael Chabinyc, professor of materials and department head, have teamed up to develop the first 3-D printable “bottle brush” elastomer. The new material results in printed objects that have an unusual softness and elasticity – mechanical properties that closely resemble those of human tissue.

Conventional elastomers, i.e. rubbers, are more rigid than many biological fabrics. This is due to the size and shape of their constituent polymers, which are long, linear molecules that easily become entangled like cooked spaghetti. In contrast, bottle brush polymers have additional polymers attached to the linear skeleton, which leads to a structure closer to a bottle brush than you might find in your kitchen. The polymeric structure of the bottle brush provides the ability to form extremely soft elastomers.

The ability to 3-D print bottle brush elastomers allows these unique mechanical properties to be exploited in applications that require careful control of the dimensions of objects ranging from biomimetic tissue to high-sensitivity electronic devices, such as touch pads, sensors and actuators.

Two postdoctoral fellows – Renxuan Xie and Sanjoy Mukherjee – played key roles in the development of the new material. Their results were published in the journal Scientific advances.

Xie and Mukherjee’s key discovery involves the self-assembly of nanoscale bottlebrush polymers, which causes a solid-liquid transition in response to applied pressure. This material is classified as a yield strength fluid, meaning it starts out as a semi-soft solid that retains its shape, like butter or toothpaste, but when sufficient pressure is applied it liquefies. and can be squeezed using a syringe. The team exploits this property to create inks in a 3D printing process called direct ink writing (DIW).

Researchers can adjust the material to flow under different amounts of pressure to match desired processing conditions. “For example, maybe you want the polymer to keep its shape under a different stress level, for example in the presence of vibration,” says Xie. “Our material can hold its shape for hours. This is important because if the material sags during printing, the printed part will have poor structural stability.”

After the object is printed, UV light is projected onto it to activate the crosslinking agents that Mukherjee has synthesized and included in the ink formulation. Crosslinking agents can bind close bottle brush polymers together resulting in an ultra-soft elastomer. At this point, the material becomes a permanent solid – it will no longer liquefy under pressure – and exhibits extraordinary properties.

“We’re starting with long polymers that aren’t crosslinked,” Xie said. “This allows them to flow like a fluid. But, after shining on them, the small molecules between the polymer chains react and are linked together in a network, so you have a solid, an elastomer that, once stretched, will return to its original shape. “

The softness of a material is measured by its modulus, and for most elastomers it is quite high, which means their stiffness and elasticity are similar to that of an elastic. “The modulus of our material is a thousand times smaller than that of a rubber band,” notes Xie. “It’s super soft – it looks a lot like human tissue – and very stretchy. It can stretch about three to four times its length.”

Accidental ink

Mukherjee discovered the material by accident, while trying to develop a material for a different project, which would increase the amount of charge that an actuator could store. When the elastomer came to Xie for characterization, he immediately knew it was special. “I could tell right away that it was different, because he could hold his form so well,” he recalls.

“When we saw this really well-defined yield strength, everyone collectively realized that we could print it in 3-D,” Bates said, “and that would be cool, because none of the printable materials in 3-D that we know to have this super soft property. “

Bottlebrush polymers have been around for over twenty years. But, said Bates, “The field has exploded over the past decade thanks to advances in synthetic chemistry that offer exquisite control over the size and shape of these unique molecules.

“These super soft elastomers could be applicable as implants,” he added. “You may be able to reduce inflammation and rejection by the body if the mechanical properties of an implant match the native tissue.”

Another important part of the new material is that it is a pure polymer, noted Chabinyc.

“There is no water or other solvent to make them artificially softer,” he said.

To understand the importance of not having water in the polymer, it helps to think about Jell-O, which is primarily water and can hold its shape, but only as long as the water stays in the interior. “If the water left, then you would just have a pile of shapeless matter,” said Chabinyc. “With a conventional polymer, you have to figure out how to conserve the right amount of water to maintain its structure, but this new material is all solid, so it will never change.”

In addition, the new material can be 3-D printed and processed solvent-free, which is also unusual. “People often add solvent to liquefy a solid so that it can be pulled out of a nozzle,” Xie said, “but if you add solvent it has to evaporate after printing, so the object changes shape or cracks. “

Mukherjee added, “We wanted the material and the printing process to be as clean and straightforward as possible, so we played a chemistry trick with solubility and self-assembly, which enabled the solvent-free process. . The fact that we don’t use a solvent is a huge plus. ”

Code for fine-tuning elastomers to mimic biological materials

Renxuan Xie et al, Room temperature 3D printing of super soft, solvent-free elastomers, Scientific advances (2020). DOI: 10.1126 / sciadv.abc6900

Provided by University of California – Santa Barbara

Quote: New material gives soft and elastic objects that resemble human tissue (2021, February 8) retrieved February 8, 2021 from https://phys.org/news/2021-02-material-yields-soft-elastic- human.html

This document is subject to copyright. Apart from any fair use for study or private research, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link