[ad_1]

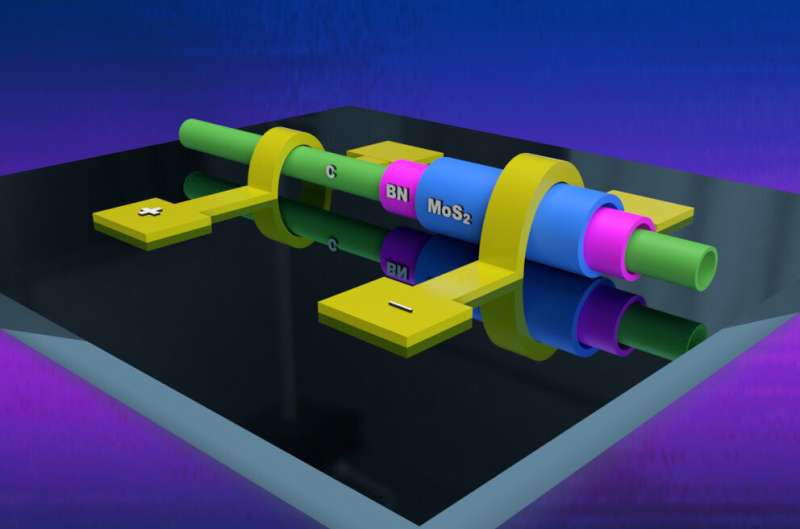

Image of heterotube diode: This device contains MoS2 semiconductor shell (blue), on hBN insulating shell (purple), on carbon nanotube core (green) of heteronanotube coated with gold electrodes ( yellow). Credit: Elizabeth Flores-Gomez Murray / Penn State

The recent synthesis of one-dimensional van der Waals heterostructures, a type of heterostructure made by superimposing two-dimensional materials one atom thick, may lead to new miniaturized electronics that are currently not possible, according to a team of Penn State and University of Tokyo Researchers.

Engineers typically produce heterostructures to achieve new device properties that are not available in a single material. A van der Waals heterostructure is a heterostructure made of 2D materials that are stacked directly on top of each other like Lego blocks or a sandwich. The van der Waals force, which is a force of attraction between uncharged molecules or atoms, holds materials together.

According to Slava V. Rotkin, Penn State Frontier professor of engineering and mechanics, the one-dimensional van der Waals heterostructure produced by researchers is different from the van der Waals heterostructures that engineers have produced so far.

“It looks like a stack of 2D layered materials that are coiled into a perfect cylinder,” Rotkin said. “In other words, if you roll a sandwich you keep all the good stuff where it should be and don’t move, but in this case you also make it into a thin cylinder, very compact like a hot dog or a This way, 2D materials are always in contact with each other in a desired vertical heterostructure sequence, regardless of their side edges, all rolled up, which is a big deal in making very small devices. “

The team’s research, published in ACS Nano, suggests that all 2D materials could be coiled into these one-dimensional heterostructured cylinders, called hetero-nanotubes. Researchers at the University of Tokyo recently fabricated electrodes on a hetero-nanotube and demonstrated that it can function as an extremely small diode with high performance despite its size.

“Diodes are a major type of device used in optoelectronics – they are at the heart of photodetectors, solar cells, electroluminescent devices, etc.,” Rotkin said. “In electronics, diodes are used in several specialized circuits; although the main element of electronics is a transistor, two diodes, connected back to back, can also serve as a switch.”

This opens up a potential new class of materials for miniaturized electronics.

“It takes 2D materials technology to a new level, potentially enabling a new generation of electronic and optoelectronic devices,” Rotkin said.

Rotkin’s contribution to the project was to solve a particularly difficult task, which was to ensure that the one-dimensional van der Waals heterostructured cylinder had all the required layers of material.

“Using the sandwich analogy again, we needed to know if we had a shell of ‘roast beef’ the length of a cylindrical sandwich or if there were areas where we only had shells. of ‘bread’ and ‘lettuce’, “Rotkin said. “The lack of an intermediate insulating layer would mean that we failed in the synthesis of the device. My method explicitly showed that the middle shells were all there along the entire length of the device.”

In regular and flat van der Waals heterostructures, confirmation of the existence or absence of certain layers can be done easily because they are flat and have a large area. This means that a researcher can use different types of microscopies to collect a large amount of signal from the large flat areas, so that they are easily visible. When researchers roll them up, as in the case of a one-dimensional van der Waals heterostructure, it becomes a very thin, wire-like cylinder that is difficult to characterize because it emits little signal and becomes virtually invisible. Moreover, in order to prove the existence of an insulating layer in the semiconductor-insulator-semiconductor junction of the diode, it is necessary to solve not only the outer envelope of the hetero-nanotube, but that of the middle , which is completely shaded from the outside. shells of a molybdenum sulfide semiconductor.

To solve this problem, Rotkin used a near-field scattering scanning optical microscope that is part of the Material Research Institute’s 2D Crystal Consortium, which can “see” nanoscale objects and determine the optical properties of their materials. He also developed a special method of data analysis known as nanoscale resolution hyperspectral optical imaging, which can distinguish different materials and thus test the structure of the one-dimensional diode along its entire length.

According to Rotkin, this is the first demonstration of the optical resolution of a hexagonal boron nitride (hBN) shell in the framework of a hetero-nanotube. Much larger pure hBN nanotubes, made up of many hBN shells without any other type of material, have been studied in the past with a similar microscope.

“However, the imaging of these materials is quite different from what I’ve done before,” Rotkin said. “The beneficial result is in the demonstration of our ability to measure the optical spectrum of the object, which is an inner shell of a wire only two nanometers thick. It is comparable to the difference between being able to see a log. in wood and be able to recognize a graphite stick inside the pencil through the walls of the pencil. “

Rotkin plans to expand his research to expand hyperspectral imaging to better resolve other materials, such as glass, various 2D materials, and protein tubules and viruses.

“It’s a new technique that will hopefully lead to future discoveries,” Rotkin said.

Robot developed for the automated assembly of design nanomaterials

Ya Feng et al, One-dimensional van der Waals heterojunction diode, ACS Nano (2021). DOI: 10.1021 / acsnano.1c00657

Provided by Pennsylvania State University

Quote: Sushi-Type Rolled 2D Heterostructures May Lead to New Miniaturized Electronics (2021, March 10) Retrieved March 11, 2021 from https://phys.org/news/2021-03-sushi-like-2d-heterostructures-miniaturized -electronics. html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link