[ad_1]

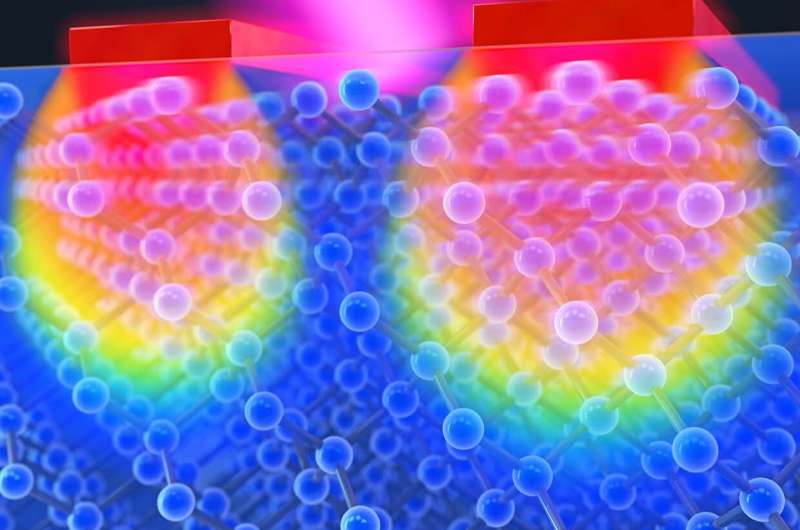

A laser heats ultra-thin silicon bars. Credit: Steven Burrows / JILA

A team of physicists at CU Boulder has solved the mystery behind a puzzling phenomenon in the nano realm: why some ultra-small heat sources cool faster if you move them close together. The results, published today in the journal Proceedings of the National Academy of Sciences (PNAS), could one day help the tech industry to design faster electronic devices that overheat less.

“Often times heat is a difficult consideration in electronics design. You build a device and then find it heats up faster than you want,” said study co-author Joshua Knobloch, postdoctoral research associate. at JILA, a joint research institute between CU Boulder and the National Institute of Standards and Technology (NIST). “Our goal is to understand the fundamental physics involved so that we can design future devices to effectively manage heat flow.”

The research began with an unexplained observation: In 2015, researchers led by physicists Margaret Murnane and Henry Kapteyn at JILA were experimenting with metal bars several times thinner than the width of a human hair on a silicon base. When they heated these bars with a laser, something strange happened.

“They behaved in a very counterintuitive manner,” Knobloch said. “These nanoscale heat sources don’t usually dissipate heat efficiently. But if you pack them together, they cool much faster.”

Now researchers know why this is happening.

In the new study, they used computer simulations to track the passage of heat from their nanoscale bars. They found that when they brought the heat sources closer together, the energy vibrations they produced began to bounce off each other, dispersing the heat and cooling the bars.

The group’s findings highlight a major challenge in designing the next generation of tiny devices, such as microprocessors or quantum computing chips: when you scale yourself down to very small scales, heat doesn’t always behave like you think so.

Atom by atom

Heat transmission in devices is important, the researchers added. Even tiny flaws in the design of electronics like computer chips can allow temperature to build up, increasing wear and tear on a device. As tech companies strive to produce ever smaller electronic devices, they will need to pay more attention than ever to phonons, vibrations of atoms that carry heat in solids.

“The heat flow involves very complex processes, which makes it difficult to control,” Knobloch said. “But if we can understand how phonons behave on a small scale, then we can tailor their transport, which allows us to build more efficient devices.”

To do this, Murnane and Kapteyn and their team of experimental physicists joined forces with a group of theorists led by Mahmoud Hussein, professor in the Ann and HJ Smead department of aerospace engineering sciences. His group specializes in the simulation or modeling of the movement of phonons.

“On an atomic scale, the very nature of heat transfer is emerging in a new light,” said Hussein, who also has a courtesy appointment in the physics department.

The researchers essentially recreated their experiment from several years ago, but this time, entirely on a computer. They modeled a series of silicon bars, laid side by side like the slats of a railroad track and heated them.

The simulations were so detailed, Knobloch said, that the team was able to track the behavior of every atom in the model, millions in all, from start to finish.

“We were really pushing the memory limits of the Summit supercomputer at CU Boulder,” he said.

Direct the heat

The technique paid off. The researchers found, for example, that when they spread their silicon bars far enough apart, heat tended to escape from these materials in a predictable way. Energy leaked out of the bars and into the material below, dissipating in all directions.

However, when the bars got closer, something else happened. As the heat from these sources dispersed, it effectively forced that energy to flow more intensely away from the sources, like a crowd of people in a stadium jostling against each other and leaping by. the exit. The team called this phenomenon “directional heat channeling”.

“This phenomenon increases heat transport down into the substrate and away from heat sources,” Knobloch said.

Researchers suspect that engineers may one day exploit this unusual behavior to better understand how heat flows through small electronic devices, directing that energy along a desired path, instead of letting it run freely and freely.

For now, researchers see the latest study as what scientists from different disciplines can do when working together.

“This project was an exciting collaboration between science and engineering, where the advanced methods of computational analysis developed by Mahmoud’s group were essential to understanding the behavior of new materials discovered earlier by our group using new extreme ultraviolet quantum light sources, “said Murnane, also a professor of physics.

CU Boulder’s other co-authors on the new research include Hossein Honarvar, postdoctoral researcher in aerospace engineering sciences and JILA and Brendan McBennett, graduate student at JILA. Former JILA researchers Travis Frazer, Begoña Abad and Jorge Hernandez-Charpak also contributed to the study.

New heat management material keeps computers cool

Directional thermal channeling: Phenomenon triggered by tight compression of heat sources, Proceedings of the National Academy of Sciences (2021). DOI: 10.1073 / pnas.2109056118

Provided by the University of Colorado at Boulder

Quote: Nanoscale Discovery Could Help Cool Overheating in Electronics (2021, September 20) Retrieved September 20, 2021 from https://phys.org/news/2021-09-nano-scale-discovery- cool-overheating-electronics. html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link