[ad_1]

As I mentioned in several episodes, humanity is going through a period of transition, a propitious time to launch material out of Earth's gravity well into orbit and beyond. But it's really expensive, up to $ 10,000 a pound in orbit, and 10 times more if you want it on the moon.

But over the next few decades, more and more of our space infrastructures will be built in the spacemade from materials that have been extracted in the space.

The only thing that will really have to leave the sticky gravity of the Earth will be us, the humans, the tourists, eager to visit all this space infrastructure.

Of course, to achieve this spatial future, engineers and mission planners will have to design and build the technology that will make this possible.

This involves testing new prototypes, technologies and methodologies for mining and space manufacturing.

This is an example of the type of telecommunication satellite launched regularly in space. The size and shape of its solar panels depend on reality: the gravity of the Earth … is zero. Any spaceship built must be able to support all gravity, here on Earth, throughout the test phase.

Then he must be able to handle sudden acceleration, jolts and other throwing forces. Once in orbit, it must deploy its solar panels in a configuration that can generate energy for the spacecraft.

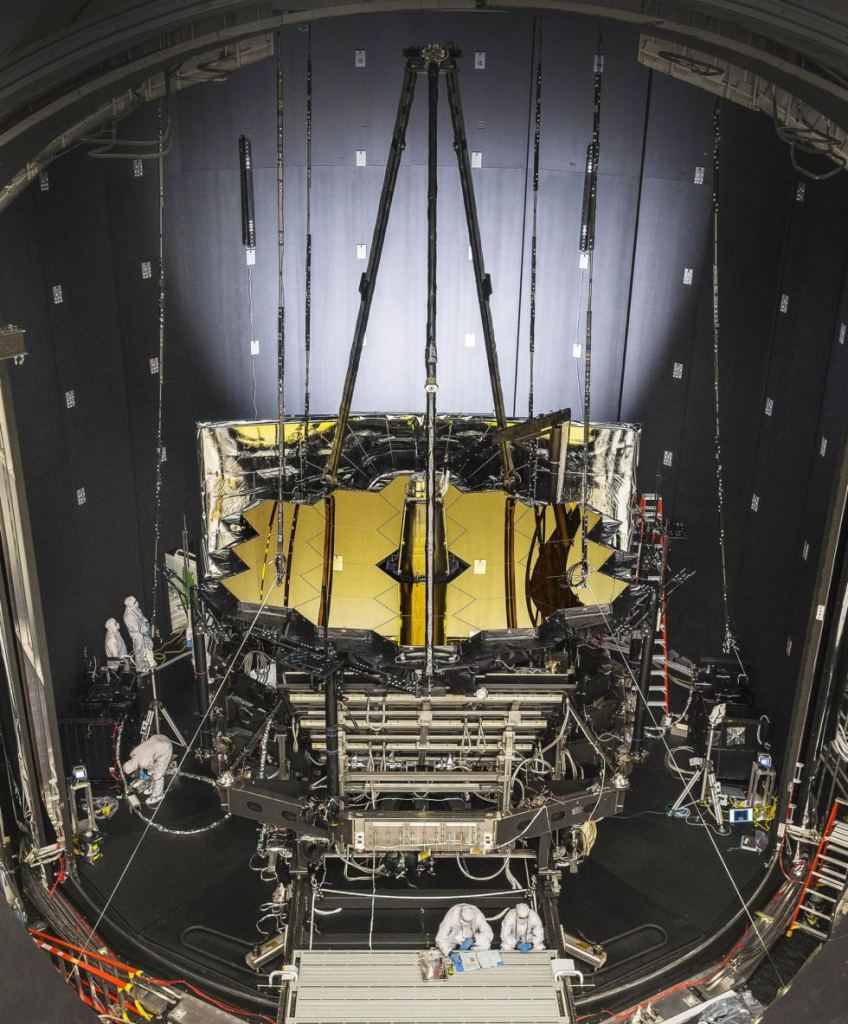

As always, I just have to say these words, James Webb Space Telescope, to put you in a state of panic and dread, imagining the complexity and precision of origami that must occur at most. from one million kilometers from Earth, in a place not to be repaired.

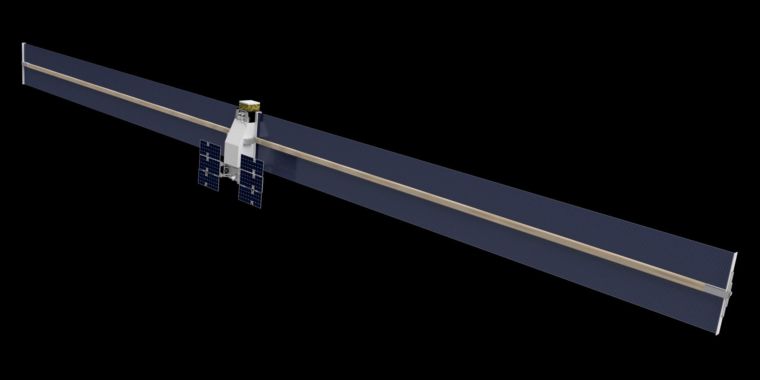

Now, take a look at this artist's illustration of a satellite whose solar panels were entirely built in orbit, without ever suffering the rigors of Earth's gravity. They are comically, hilariously tall. And as it turns out to be efficient and profitable.

Imagine the International Space Station with solar panels three times longer, but still perfectly robust and stable in the microgravity environment in low Earth orbit.

It is this technology that the Archinaut 1 of Made in Space will test from 2022, which will bring us a little closer to space-based manufacturing, which I continue to pursue.

In July 2019, NASA announced the award of $ 73.7 million to Made In Space, a 3D product manufacturing company based in Mountain View, California.

This contract will help finance the construction and launch of the company's Archinaut One spacecraft, which will then demonstrate the manufacture and assembly of spacecraft components in space.

They will build a spaceship that will assemble its own power system. In the space.

If all goes well, Archinaut One will depart aboard a Rocket Lab Electron rocket from New Zealand as early as 2022.

Once in orbit, the satellite will build two ten-meter solar panels, enough to power a standard 200-kg satellite. The type of satellite that serves as a secondary payload for larger launches. Generally, they are malnourished and only have a few hundred watts.

Archinaut One will print the support beams in 3D, then deploy the solar panels on either side of the probe.

By fabricating the entire matrix in space, the smaller satellite will have the capabilities of a much larger spacecraft – five times more powerful – to power more scientific instruments, more power and more space. communication instruments, etc.

This makes sense here in Earth orbit, but it makes even more sense in the solar system, where the amount of solar energy available to a spacecraft decreases.

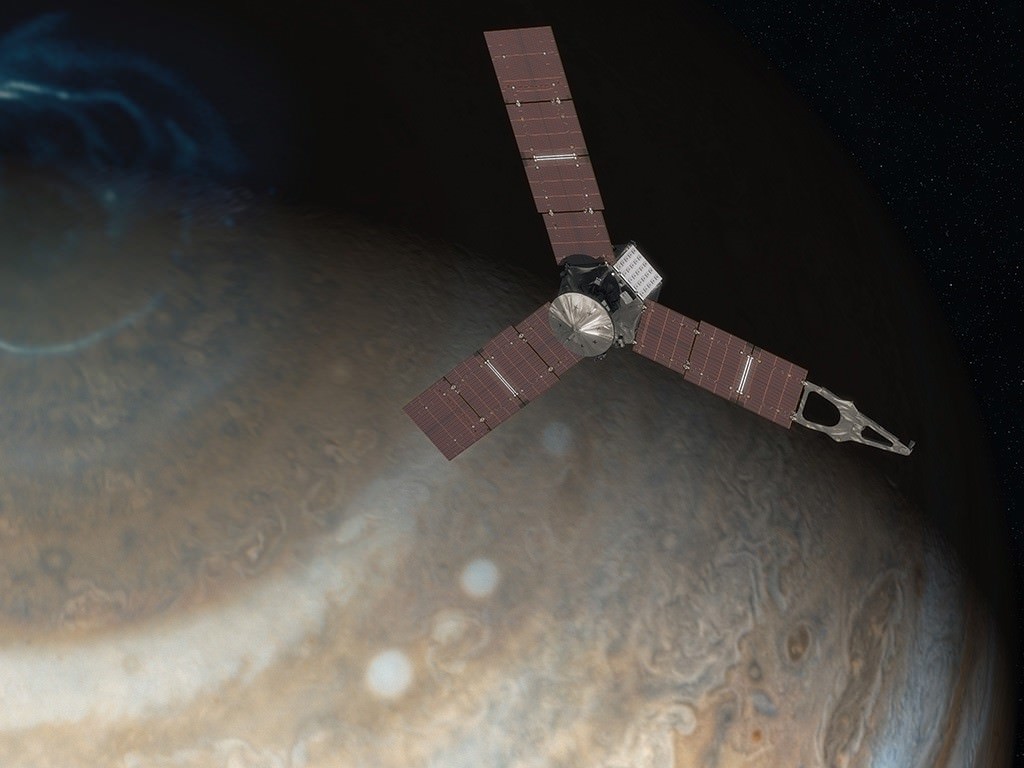

NASA's Juno satellite is currently visiting Jupiter. The 4-ton satellite has three 9-meter solar panels containing 18,698 solar cells. Here on Earth they are able to generate 14 kilowatts of electricity. But in Jupiter's orbit, solar cells receive only a quarter of the sun's light.

NASA has invested in several technologies that it calls "tipping points". These are technologies that are too risky or too complicated for aerospace companies to grow profitably. But if NASA could reduce risk, they could take advantage of the exploration of the commercial space.

This was the second contact made to Made in Space for the Archinaut program. The first contract, awarded in 2016, concerned an Archinaut ground test.

It has been placed in Northrop Grumman's thermal vacuum test environment, which can mimic the extreme temperatures and low pressure of near-vacuum space.

Inside the chamber, Archinaut was able to manufacture and assemble various structures. He demonstrated that it was possible to assemble prefabricated components such as knots and trusses in a completely autonomous way, as well as various repair operations.

Once these tests are completed, the next step will be to test the technology in space, with the ideal launch of Arbinaut One by 2022.

In addition to the Archinaut program, NASA has been collaborating with Made in Space for several years.

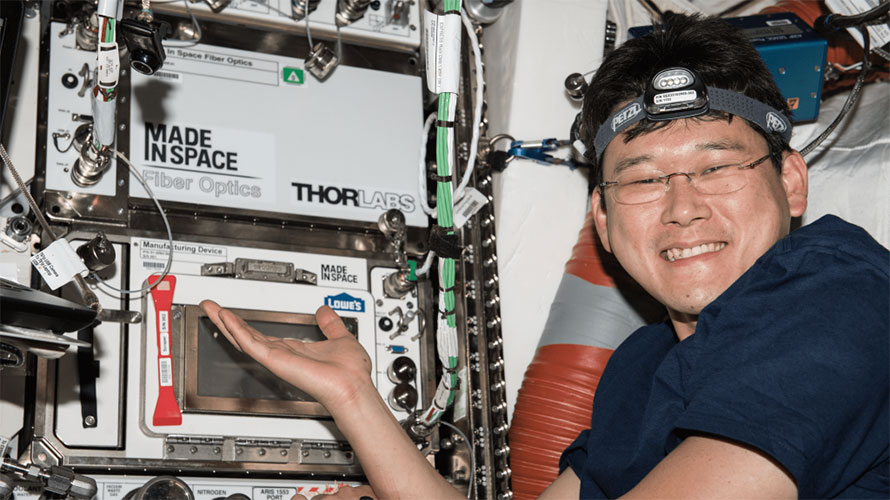

The most famous of this partnership is the Additive Manufacturing Facility (AMF), currently installed aboard the International Space Station, arrived in March 2016, offering an upgrade to the station's previous printer.

In recent years, this printer has made dozens of objects in the microgravity environment in polyethylene orbit. But the AMF is able to print with different materials such as metals and composites.

The partnership with Made in Space allows NASA to manufacture spare parts and repair broken parts of the station in orbit. But it also allows Made in Space to test their more ambitious projects of integral manufacturing in space.

In 2018, NASA awarded them the Phase 2 Small Business Innovation Research Award for their Vulcan manufacturing system. It is a space-based manufacturing system that can work with 30 different materials, such as aluminum, titanium or plastic composites, to print 3D articles. .

Vulcan will also be able to subtract material by machining parts to their final shape. And everything will be done in a robotic way. The goal is to build in orbit polymer and metal components of high strength and high precision, at the same level of quality that you can buy here on Earth.

Made in Space is also testing fiber optic manufacturing technology in space. These fibers transmit a huge amount of data, but the signal needs to be amplified over longer transmission distances. There is a special kind of crystal called ZBLAN that could have a tenth or even one hundredth of the signal loss of traditional fibers, but it is difficult to make gravity on Earth.

A recent experiment delivered to the International Space Station will allow these ZBLAN fibers to be produced in space, hoping to produce up to 50 km at a time. As launch costs are low, it may even be profitable to make fiber optic cables in space and then bring them back to Earth.

But it is also wise to keep them in space, to create more sophisticated satellite equipment, which has never known the gravity of the Earth.

Made in Space is also working on a technology to recycle polyethylene in new 3D printed elements. When it is so expensive to carry cargo in orbit, you must recycle what you have already sent into space, and prevent it from falling into the sea and burning it into orbit.

These are just part of a much larger technological strategy that Made in Space is working on: the goal of a space-based manufacturing and assembly system.

In the future, satellites, telescopes and other space materials will be designed here on Earth. Then the raw materials will be launched into space with an Archinaut manufacturing system.

Archinaut will manufacture all components using its 3D printer, then they will be assembled in space.

Made in Space offers two types of Archinaut that they currently offer. The DILO system looks like an octagonal canister surrounded by solar panels with a protruding robotic arm.

The cartridge contains all the raw materials of a space communication antenna. The arm takes folded reflector panels and then assembles them. He uses 3D printing to fix the panels, which are then unfolded in a communication dish.

The spacecraft then uses a 3D printer to fabricate and extrude a communications boom from its center.

The more advanced version is called ULISSES. It is a version of Archinaut with three robotic arms surrounding a 3D printer. The spacecraft makes various farms and knots, then uses its arms to assemble them into larger structures. With this technology, they are really limited only by the amount of raw materials with which the spacecraft has to work.

He could build space telescopes over tens or even hundreds of meters.

The pieces assemble for a truly spatial manufacturing and assembly. As early as 2022, we will see a spaceship assembling its own solar panels in space, creating a structure that will never need to experience Earth's gravity.

And in the coming years, we will see more and more spacecraft built almost entirely in orbit. And finally, I hope that they will be made from materials harvested in the solar system.

One day we will see the launch of the latest cargo rocket. The last time we took the trouble to carry something out of the massive gravity of the Earth, well in space. From there, it will only be tourists.

[ad_2]

Source link