[ad_1]

Research led by bioengineers from Rice University and the University of Washington (UW) have advanced the possibility of performing bioimpression of human organs from living cells and hydrogels .

By adding common food dyes, the hydrogels used in the experiment were made photocurable for DLP printing and adapted to the intended application. Researchers have identified dietary dyes based on natural products such as turmeric powder and blueberries as "non-toxic light blockers", compared to Sudan I, an organic compound that is unsuitable for biological applications.

By using non-toxic hydrogels and DLP printing, scientists have managed to create a complex network of physically and chemically nested vessels.

In addition to this, the ability to transplant the structure into mice with liver injury was also evaluated. The next step in the research is to make these tissues scalable so that they can be transplanted into the human body.

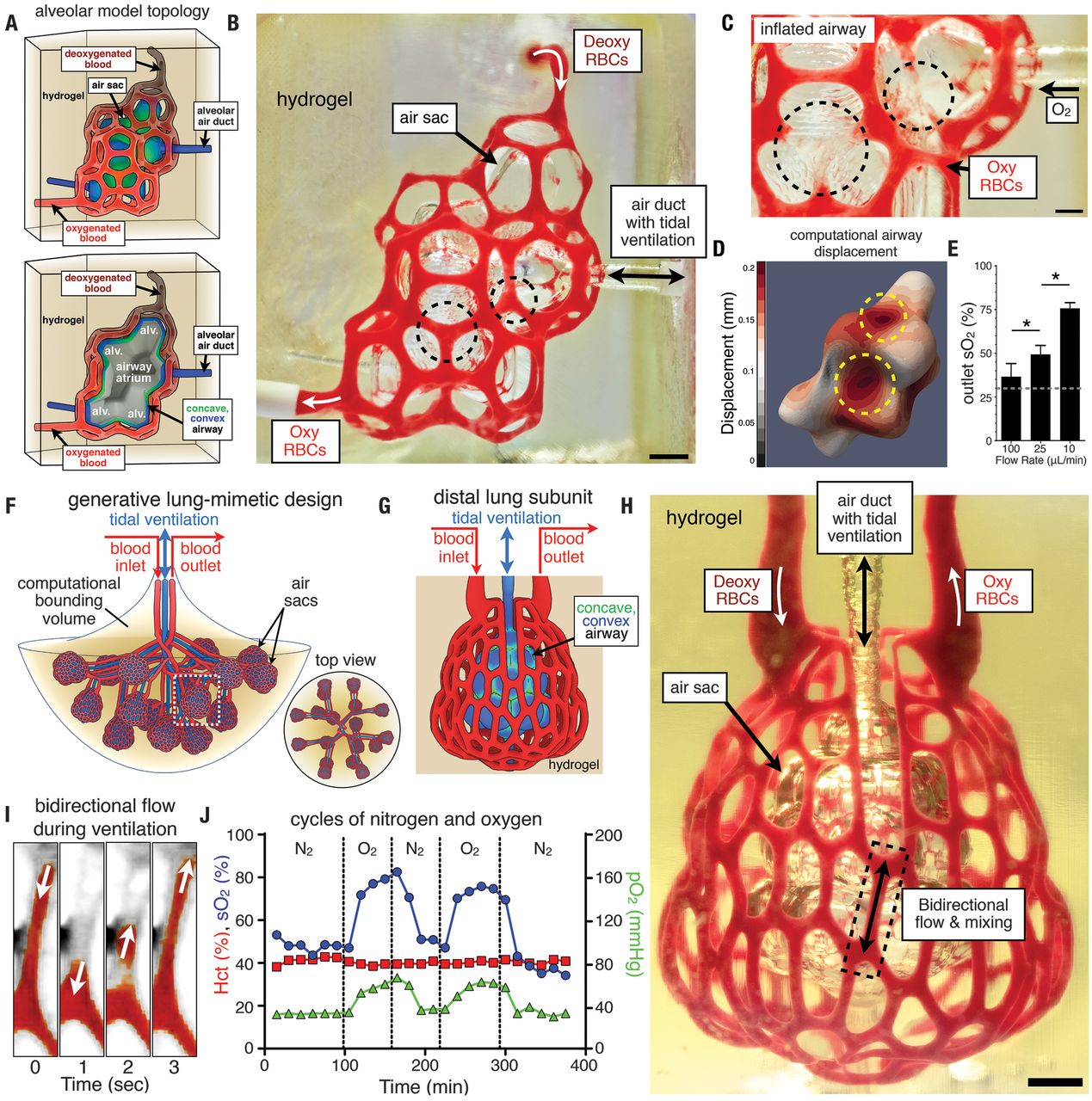

Imitating the human lung

Using live cells, hydrogels and a DLP printer, an inflatable bag surrounded by multivascular tubes was bio-printed. The organ mimics the behavior of a human lung.

Jordan Miller, Assistant Professor of Bioengineering at Rice's Brown School of Engineering and one of the leading researchers, explained:our organs actually contain independent vascular networks – such as the airways and blood vessels of the lung or bile ducts and blood vessels of the liver. These interpenetrating networks are physically and biochemically entangled and the architecture itself is intimately related to tissue function. "

"Our technology is the first bio-printing technology to address the challenge of multivascularization in a direct and comprehensive way."

Replacement of organ

According to the British NHS, there are currently more 6000 people waiting for an organ transplant, while in the United States, the figure is nearly 114,000.

One of the main risks of organ transplantation is that the host's immune system can reject the transplanted organ, thus putting the patient's life at risk.

Through bioimpression, organs can be created from the patient's cells. This could potentially minimize the risk of rejection of the transplant.

However, for several decades, the difficulty of creating complex vascular networks within soft materials in which cells can grow is a major obstacle to the progress of bioimprint organs. As Miller explains, "One of the most important barriers to the generation of functional tissue replacements has been our inability to print the complex vascular system capable of providing nutrients to densely populated tissues."

Bio-Impression of Human Organs

In the most recent research, bioengineers have managed to create an air pocket surrounded by a complex tubular structure mimicking blood vessels. The pumping of the air bag facilitates the mixing of blood in the surrounding vessels.

Kelly Steven, assistant professor of bioengineering and research director at UW, said: "Through this work, we can now better ask ourselves the following question:" If we can print fabrics that look and that breathe more even those who are healthy in our body, will they also be functional? to behave more like these fabrics? This is an important question because to what extent will the functions of a bio-printed tissue affect its effectiveness as a therapy. "

"The liver is particularly interesting because it performs 500 amazing functions, probably right behind the brain. […] The complexity of the liver means that there is currently no machine or therapy that can replace all its functions in case of failure. The bio-printed human organs could someday provide this therapy. "

Much of the research material was assisted by open source 3D printing technology, including RepRap, UltiMachine and Prusa. For the purposes of the study, the research team created an open source DLP bioprinter called "stereolithography apparatus for tissue engineering" or SLATE.

In addition, Miller and Bagrat Grigoryan, a civil engineering student at Rice, had the idea of adding dye to food dyes that could allow the hydrogel to absorb blue light. and make it photocurable.

The authors of the state of the research indicate that "we have identified candidate photosorbents among food additives whose absorbance spectra include wavelengths of visible light that can be used for biocompatible photopolymerization".

The design of the airbag was done in collaboration with Nervous System, a design studio based in Massachusetts.

Bioprinting and regenerative medicine

In recent years, 3D printing has shed new light on regenerative medicine. Among the recently reported bioprinting applications include treatment of scarring, use of stem cells and bioprinting to create tendons and ligaments.

In the coming years, bio-printing technology is expected to grow faster, Miller said., "We envision that bioprinting will become a major component of medicine in the next two decades."

The research team has made the hydrogel design file available to the public. Miller said, "Making the hydrogel design files available will allow others to explore our efforts here, even if they use a future 3D printing technology that does not exist. not today,

"We are only at the beginning of our exploration of the architectures found in the human body […] We still have a lot to learn.

The paper concludes, "We have identified readily available food dyes that can serve as potent photoabsorbers for the biocompatible and cytocompatible production of hydrogels containing functional vascular topologies for studies on fluid mixers, valves, intravascular transport. , nutrient distribution and host intake. "

"Thanks to our stereolithographic process, there is a potential for simultaneous and orthogonal control of tissue architecture and biomaterials for the design of regenerative tissues."

The research discussed in this article is published as Multivascular networks and functional intravascular topologies within biocompatible hydrogels in the newspaper Science. It was written jointly by Bagrat Grigoryan, Samantha J. Paulsen, Daniel C. Corbett, Daniel W. Sazer, Chelsea L. Fortin, Alexander J. Zaita, Paul Greenfield, Nicholas J. Calafat, John P. Gounley and Anderson H Ta, Fredrik Johansson, Amanda Randles, Jessica E. Rosenkrantz, Jesse D. Louis-Rosenberg, Peter A. Galie, Kelly R. Stevens, and Jordan S. Miller.

The prices of 3D printing 2019 are almost there. Vote now in the category of 3D printing for a better world.

To learn more about bio-printing and regenerative medicine, subscribe to our newsletter on 3D printing. You can also get live updates by following us on Twitter and Facebook.

For jobs in the manufacturing industry, visit our 3D Printing Jobs page.

The image shown shows the airbag resembling a bioprinted lung. Image via the University of Washington.

[ad_2]

Source link