[ad_1]

Shinichi Sakamoto is 57 years old and works for Shimizu, one of the largest construction companies in Japan.

This is part of an aging workforce.

"Statistics show that one-third of workers (construction workers in Japan) are over 54 years old and plan to retire soon," said Sakamoto, deputy chief executive. Shimizu Production Technology

These employees are not replaced by younger employees. "The number of workers under 30 is just over 10%," he says.

In September, Sakamoto's company acquires a promising new worker: a robot.

The Robo-Carrier is currently working on the construction of a building in Osaka, carrying heavy plasterboard every night.

This machine is not the only colleague of Sakamoto.

Freelancers

Robo-Welder welds steel columns, while Robo-Buddy inserts suspension bolts and installs roof boards.

Robots operate autonomously and perform the functions badigned to them by a supervisor. a tablet .

The Robo-Carrier can escape obstacles and the Robo-Welder uses a laser to determine the contours of the object to be welded.

"There must be more and more robots in constructions " says Sakamoto. "Labor shortages are a problem at the national level."

The number of construction workers in Japan will fall to 2.2 million by 2025 (compared with 3.4 million in 2014), according to the Shimizu Construction Company. [19659014] Growing Market

In other countries, the construction sector is also turning more and more to robots.

The construction robot market reached 200 million US dollars in 2017 and by 2025 it should be transferred. According to the consultant QY Research, this amount should reach 420 million US dollars.

] In the United States, construction workers are also aging. According to Jeremy Searock, co-founder of Advanced Robotics Robotics Factory, the average age is currently 43 years old.

Ten years ago, the average age was about 35 years old.

80% of American entrepreneurs. UU According to a survey conducted in August

There is a "clear trend," says Searock. "The younger generations do not enter the field of construction."

That's the reason why Shimizu has invested $ 179 million since 2015 to develop construction robots, spokesman Hideo Imamura said. Their robots reduce the labor requirements for a given task by 70% to 80%, he says.

In the United States, c therefore half the jobs of According to researchers at the University of Illinois and the Midwest Economic Policy Institute, the construction could be replaced by robots for 2057 .

In addition to being tireless, robots can perform the most difficult and dangerous jobs on a construction site. Sakamoto, said Sakamoto, could prevent injuries and deaths.

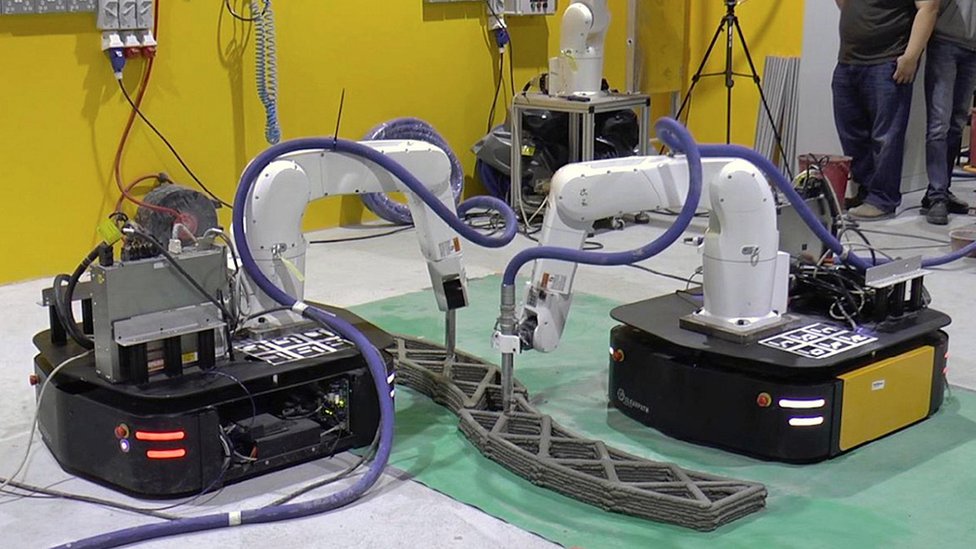

5G mobile networks will improve connectivity and facilitate the cooperation of multiple robots.

Many small robots and perform different parts of an identical task .

3D printing robots developed by the Nanyang Technological University in Singapore, for example, can print concrete on a computer map.

Currently, Shimizu controls its robots using 4G mobile networks and wireless internet, which means they work in m buildings. from height, they must extend the range of the wireless network by signal repeaters.

The 5G will put an end to this inconvenience, says the firm.

Hard Work

One of the most difficult parts of bridge construction is joining steel reinforcement bars that reinforce concrete.

There can be hundreds of thousands or even millions of intersections to fix.

So, in 2017, Advanc ed Construction Robotics developed a robot, TyBot, to perform this work on the Freedom Road Bridge in Pennsylvania

. He connected 24,000 intersections of rebar bars at a rate of 5.5 seconds each.

The National Institute of Advanced Industrial Science and Technology of Tokyo has built a prototype robot, called HRP-5P, to install gypsum partitions.

Construction Robotics, of New York, recently built a semi-automatic mason that placed 250,000 bricks in a Virginia building.

Creators, place 380 bricks per hour, making it six times faster than a human mason.

Given the shortage of manpower, the first construction companies using efficient robots will have an important advantage. Will Hughes, professor of economics and construction administration at the University of Reading, UK

So do not worry if in a few years you open the door of your house and see a robot .

be there to transform your apartment.

You can now receive notifications from BBC News World. Download the new version of our application and activate it to not miss our best content .

[ad_2]

Source link