[ad_1]

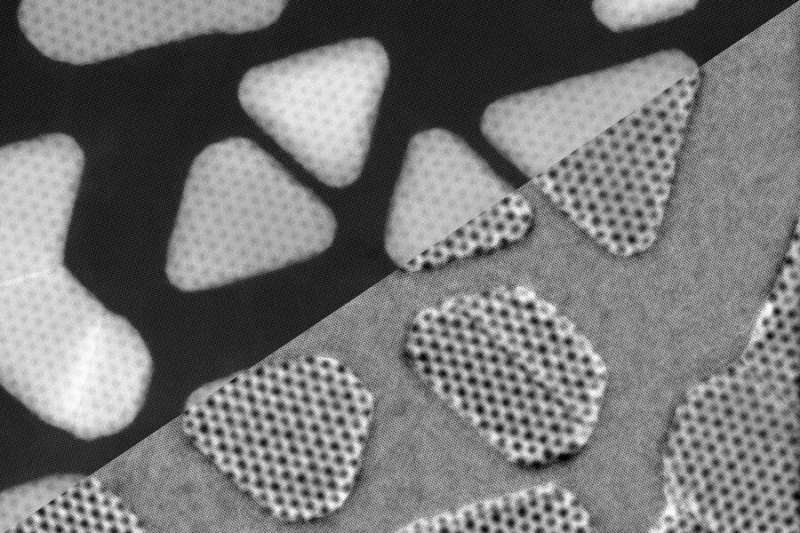

Caption: These “island” images of gold atoms deposited on a two-dimensional molybdenum sulfide layer were produced by two different modes, using a new scanning electron microscope (STEM) in the new MIT facility. nano. By combining data from the two different modes, the researchers were able to understand the three-dimensional arrangement of the atoms where the two materials meet. Credit: Massachusetts Institute of Technology

In recent years, engineers have found ways to modify the properties of some “two-dimensional” materials, which are only one or a few atoms thick, by stacking two layers together and rotating one slightly in relation to it. to the other. This creates what’s called moiré patterns, where tiny changes in the alignment of the atoms between the two sheets create patterns on a larger scale. It also changes the way electrons move through material, in potentially useful ways.

But for practical applications, such two-dimensional materials must at some point connect with the ordinary world of 3D materials. An international team led by researchers at MIT has now developed a way to imagine what is happening at these interfaces, down to the level of individual atoms, and to correlate the moiré patterns at the 2-D-3 border. -D with the result changes in the properties of the material.

The new findings are described today in the journal Nature communications, in an article by MIT graduate students Kate Reidy and Georgios Varnavides, materials science and engineering professors Frances Ross, Jim LeBeau and Polina Anikeeva, and five others at MIT, Harvard University and University of Victoria in Canada.

Pairs of two-dimensional materials such as graphene or hexagonal boron nitride can exhibit amazing variations in their behavior when the two sheets are just twisted slightly relative to each other. This causes the wire mesh atomic lattices to form moiré patterns, the odd kinds of bands and drops that sometimes appear when taking a photo of a printed image or through a window screen. In the case of 2-D materials, “it seems like anything, all the interesting properties of materials you can think of, you can kind of modulate or change by twisting the 2-D materials relative to each other. says Ross, who is the Ellen Swallow Richards Professor at MIT.

While these 2D pairings have captured the attention of scientists around the world, she says, little is known about what happens when 2D materials encounter regular 3D solids. “What interested us about this,” says Ross, “is what happens when a 2D material and a 3D material are put together. First, how do you measure atomic positions at and near the interface? Second, what are the differences between a 3-D-2-D interface and a 2-D-2-D interface? And third, how you can control it – is there a way to deliberately design the interfacial structure ” to produce the desired properties?

Determining exactly what is happening at such 2-D-3-D interfaces was a big challenge as electron microscopes produce an image of the projected sample and their ability to extract the depth information needed to analyze the details of the sample. the interface is limited. structure. But the team found a set of algorithms that allowed them to extrapolate from images of the sample, which look a bit like a set of overlapping shadows, to determine what configuration of stacked layers would produce. this complex “shadow”.

The team used two transmission electron microscopes unique to MIT that enable a combination of capabilities unmatched in the world. In one of these instruments, a microscope is connected directly to a manufacturing system so that samples can be produced on-site by deposition processes and immediately fed directly into the imaging system. It is one of the few such installations in the world to use an ultra-high vacuum system that prevents even the smallest of impurities from contaminating the sample during the preparation of the 2-D interface. 3-D. The second instrument is a scanning transmission electron microscope located at MIT’s new research facility, MIT.nano. This microscope has exceptional stability for high resolution imaging, as well as multiple imaging modes to collect sample information.

Unlike stacked 2D materials, whose orientations can be changed relatively easily by simply picking up a layer, twisting it slightly, and replacing it, the bonds holding the 3D materials together are much stronger, so the team had to develop new ones. ways to get aligned layers. To do this, they added the 3-D material over the 2-D material under ultra-high vacuum, choosing growing conditions where the layers self-assemble in a reproducible orientation with specific degrees of twist. “We had to develop a structure that was going to line up in a certain way,” says Reidy.

After growing the materials, they then had to figure out how to reveal the atomic configurations and orientations of the different layers. A scanning transmission electron microscope actually produces more information than what appears in a flat image; in fact, every point in the image contains details of the paths the electrons came in and went along (the diffraction process), as well as any energy the electrons lost in the process. All of this data can be separated so that information at all points in an image can be used to decode the actual solid structure. This process is only possible for advanced microscopes, like the one from MIT.nano, which generates an electron probe that is unusually narrow and precise.

The researchers used a combination of techniques called STEM 4-D and integrated differential phase contrast to achieve this process of extracting the entire structure at the image interface. Then, Varnavides said, they asked, “Now that we can imagine the complete structure at the interface, what does this mean for our understanding of the properties of this interface?” Researchers have shown through modeling that electronic properties should be altered in a way that can only be understood if the complete structure of the interface is included in physical theory. “What we found is that in effect this stacking, the way atoms are stacked out of the plane, modulates the electronic and charge density properties,” he says.

Ross says the results could help improve the types of junctions in some microchips, for example. “Every 2-D material used in a device has to exist in the 3-D world, and therefore it has to have a junction with three-dimensional materials,” she says. So, with this better understanding of these interfaces and new ways of studying them in action, “we are in good shape to create structures with desirable properties in a planned way rather than on an ad hoc basis.”

“The methodology used has the potential to calculate from local diffraction models acquired the modulation of the local electronic pulse,” he says, adding that “the methodology and research presented here have an exceptional future and great interest for the scientific community of materials ”.

Two-dimensional heterostructures composed of layers with slightly different lattice vectors

Kate Reidy et al, Direct imaging and modulation of the electronic structure of moiré superlattices at the 2D / 3D interface, Nature communications (2021). DOI: 10.1038 / s41467-021-21363-5

Provided by the Massachusetts Institute of Technology

This story is republished courtesy of MIT News (web.mit.edu/newsoffice/), a popular site that covers current affairs in MIT’s research, innovation and education.

Quote: Engineering of the boundary between 2-D and 3-D materials (2021, February 26) retrieved February 28, 2021 from https://phys.org/news/2021-02-boundary-2d-3d-materials.html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link