[ad_1]

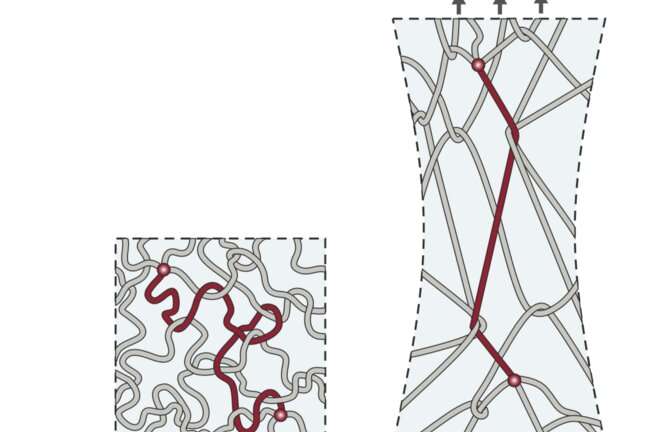

A very tangled hydrogel (left) and a regular hydrogel (right). Credit: Suo Lab / Harvard SEAS

The science of polymers has made possible rubber tires, Teflon and Kevlar, plastic water bottles, nylon jackets among many other ubiquitous features of everyday life. Elastic polymers, called elastomers, can be stretched and released repeatedly and are used in applications such as gloves and heart valves, where they must last a long time without tearing. But one conundrum has long puzzled polymer scientists: Elastic polymers can be rigid, or they can be hard, but they can’t be both.

This stiffness-toughness conflict is a challenge for scientists who are developing polymers that could be used in applications such as tissue regeneration, bioadhesives, bioprinting, wearable electronics, and soft robots.

In an article published today in Science, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have resolved this long-standing conflict and developed an elastomer that is both stiff and strong.

“In addition to developing polymers for emerging applications, scientists face an urgent challenge: plastic pollution,” said Zhigang Suo, Allen E. mechanics and materials professor and Marilyn M. Puckett, senior author of the ‘study. “The development of biodegradable polymers has once again brought us back to fundamental questions: why are some polymers resistant, but others brittle? How do you make polymers resist tearing from repeated stretching?

Polymer chains are made by bonding together monomeric building blocks. To make a material elastic, the polymer chains are crosslinked by covalent bonds. The more crosslinks there are, the shorter the polymer chains and the more rigid the material.

“As your polymer chains get shorter, the energy you can store in the material decreases and the material becomes brittle,” said Junsoo Kim, graduate student at SEAS and co-first author of the article. . “If you only have a few cross links, the chains are longer and the material is tough but too spongy to be useful.”

To develop a polymer that is both rigid and strong, researchers turned to physical rather than chemical bonds to connect polymer chains. These physical bonds, called tangles, have been known in the art for almost as long as polymer science has existed, but they are believed to only impact stiffness, not toughness.

But the SEAS research team found that with enough entanglements, a polymer could become strong without compromising stiffness. To create highly entangled polymers, the researchers used a solution of concentrated monomer precursor with 10 times less water than other polymer recipes.

Each polymer chain has a large number of entanglements along its length (left) and a crosslink at each end. A stretched polymer (middle) showing the transmission of tension to other chains. Credit: Suo Lab / Harvard SEAS

“By cramming all the monomers in this solution with less water and then polymerizing it, we forced them to tangle, like tangled threads,” said Guogao Zhang, postdoctoral researcher at SEAS and co-first author of the article. “Just like with knitted fabrics, polymers maintain their connection to each other by being physically intertwined.”

With hundreds of these tangles, only a handful of chemical crosslinks are needed to maintain the stability of the polymer.

“As elastomers, these polymers have high toughness, strength and fatigue resistance,” said Meixuanzi Shi, visiting researcher at SEAS and co-author of the article. “When polymers are immersed in water to become hydrogels, they have low friction and high wear resistance.”

This high resistance to fatigue and high wear resistance increases the durability and service life of polymers.

“Our research shows that by using entanglements rather than crosslinks, we could reduce the consumption of certain plastics by increasing the durability of the materials,” Zhang said.

“We hope that this new understanding of the structure of polymers will expand the application opportunities and pave the way for more durable and durable polymeric materials with these exceptional mechanical properties,” said Kim.

High-energy shape-memory polymer could one day help robots flex their muscles

Zhigang Suo, Fracture, fatigue and friction of polymers in which entanglements greatly exceed crosslinks, Science (2021). DOI: 10.1126 / science.abg6320

Provided by Harvard John A. Paulson School of Engineering and Applied Sciences

Quote: Elastic polymer that is both stiff and tough solves a long-standing dilemma (2021, October 7) retrieved October 8, 2021 from https://phys.org/news/2021-10-elastic-polymer-stiff-tough- long- standing.html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link