[ad_1]

Oxygen ranks up there as one of the most important resources for use in space exploration. Not only is it an essential component of rocket fuel, it is also necessary for astronauts to breathe anywhere outside of Earth’s atmosphere. The availability of this abundant resource is not a problem – it is widely available throughout the solar system. One place where it is particularly prevalent is the lunar regolith, the thin layer of material that makes up the surface of the moon. The difficulty stems from one of the quirks of oxygen – it binds to almost everything.

About 45% of the weight of regolith is oxygen, but it is bound to materials such as iron and titanium. To use both oxygen and the materials to which it is bound, they must be separated. And a British company, with support from the European Space Agency, has started testing a technique to judge its potential effectiveness on the moon.

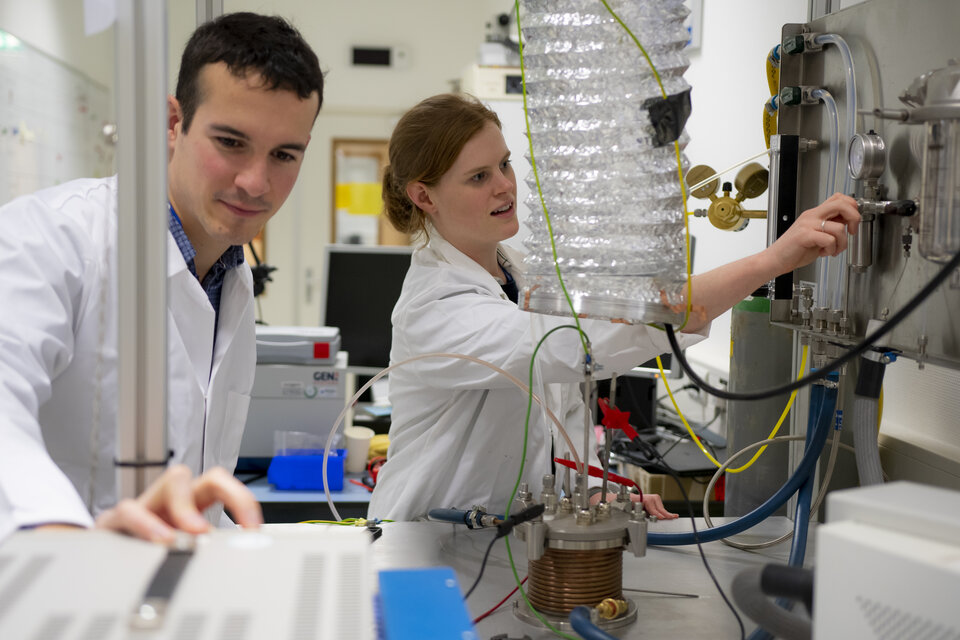

The company, called Metalysis, already makes ground-based machines capable of isolating metals in configurations bound with oxygen. In a new step, the company used its process to extract oxygen and metals from the simulated lunar regolith, which is the best proxy here on Earth for actual soil on the Moon.

The experiment worked well, but will require some adjustments to increase the amount of oxygen released. The process submerges the oxygen-containing material in a molten salt bath, then passes an electric current through the combined salt and regolith. The electrical charge allows the oxygen to break its bonds with the metals that hold it in the form of an oxide, and they are then free to migrate and collect at a charged electrode. A mixed metal powder is then left.

This metal, if properly harnessed, can be used in material deposition systems such as 3D printing, but so far it puts the cart before the horse. The Metalysis experiment performed, which takes place in a specialized chamber the size of a washing machine, is extremely energy-intensive and focuses primarily on metal mining. These three characteristics must be changed if the process is to be used efficiently in space.

Credit: Research & Impact at Sheffield Youtube

The bedroom itself will need to shrink to reasonably accommodate other space related amenities. The energy requirements will have to decrease as there is a serious lack of energy available in situ on the moon. And since oxygen is more valuable than metals on the moon, the process will need to be fine-tuned with different reagents to extract the maximum amount of oxygen from the material.

Credit: ESA

However, engineers at Metalysis and ESA still have some time before their process is needed on the moon. The current ambitious plan for NASA’s Artemis program is to get a person back to the moon in four years. If there is a system that can create rocket fuel and breathable gas for them when they arrive, it will be a big step forward in securing future exploration missions from the lunar surface.

Learn more:

ESA – Turning lunar dust into oxygen

SpaceRef – Turning moon dust into oxygen

Discover – Making Air From Moon Dust: Scientists Create Prototype Lunar Oxygen Plant

Main image credit: ESA

[ad_2]

Source link