[ad_1]

The SpaceX Falcon 9 rocket with the Dragon capsule on top is elevated to an upright position on June 2, 2021, at Launch Complex 39A at NASA’s Kennedy Space Center in Florida, in preparation for the 22nd commercial resupply services mission of the NASA for the International Space Station. NASA and SpaceX are targeting Saturday, August 28 at 3:37 a.m. EDT, for the launch of the 23rd Resupply Services Trade Mission. Credit: SpaceX

The 23 EspaceX The cargo refueling service mission carrying scientific research and technology demonstrations to the International Space Station is expected to launch in late August from NasaKennedy Space Center in Florida. Experiments on board include investigating bone health protection with botanical byproducts, testing a way to monitor crew eye health, demonstrating improved robot dexterity, exposure of building materials to the harsh environment of the space, alleviation of stress in plants, etc.

The payload highlights of this resupply mission include:

Shown with their experience packed for the launch, READI FP team members from left to right, Michele Cioffi, Program Manager; Fabio Peluso, honorary member of the MARSCenter scientific committee; Marco Fabio Miceli, systems and test engineer; and Pasquale Pellegrino, test engineer from the Aerospace Laboratory for Innovative Components (ALI) SC a rl in Italy. Credit: ALI scarl / Marcenter

Building bones with byproducts

READI FP evaluates the effects of microgravity and space radiation on the growth of bone tissue and tests whether bioactive metabolites, substances such as antioxidants formed during the breakdown of food, could protect bones during space flights. The metabolites tested come from plant extracts generated as waste from wine production.

Protecting the health of crew members from the effects of microgravity is crucial for the success of future long-duration space missions. This study could improve understanding of the physical changes that cause bone loss and identify potential countermeasures. This idea could also help prevent and treat bone loss on Earth, especially in postmenopausal women. Providing metabolites from materials that would otherwise become waste is an added benefit.

Upstream view of material for Retinal Diagnostics, an investigation testing a commercially available ophthalmic lens to capture images of the human retina in space. Credit: DLR / EAC

Keep an eye on the eyes

Retinal Diagnostics tests whether a small light-based device can capture images of the retina of astronauts to document the progression of vision problems known as space-associated neuro-ocular syndrome (SANS). The device uses a commercially available lens approved for routine clinical use and is lightweight, mobile, and non-invasive. Videos and images can be top down to test and train models to detect common signs of SANS in astronauts. The survey is sponsored by ESA (European Space Agency) with the Institute for Space Medicine of the German Aerospace Center (DLR) and the European Astronaut Center (EAC).

“SANS is present in more than two-thirds of astronauts and is believed to be associated with long-term (30 days or more) exposure to microgravity,” DLR lead researcher Juergen Drescher said. “Currently, the visual problems that can manifest with SANS are alleviated by providing eyeglasses or contact lenses to crew members. Multi-year missions to March can worsen these symptoms, and there is a need for a mobile device for the diagnosis of retinal images. Although developed for space, this mobile technology has the potential to provide diagnostics in remote and extreme environments on Earth at reduced cost. Mobile biomedical diagnostic devices like these are likely to emerge as both a catalyst for human exploration of deep space and a sustainable model for healthcare on Earth. “

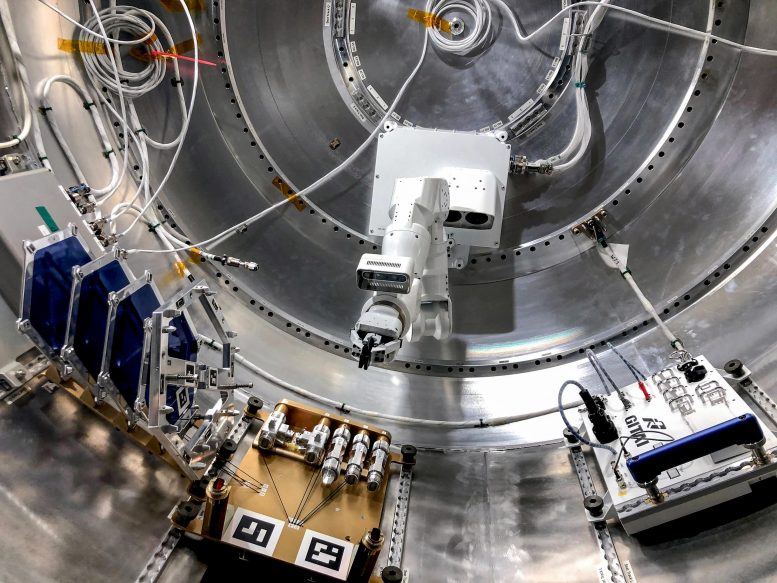

This image shows the complete configuration of the GITAI S1 robotic arm inside the Bishop model. Credit: GITAI, NRAL

Robotic aids

The Nanoracks-GITAI robotic arm demonstrates the versatility and microgravity dexterity of a robot designed by GITAI Japan Inc. The results could support the development of robotic work to support crew activities and tasks, as well as crew tasks. maintenance, assembly and manufacturing in orbit. Robotic support could reduce costs and improve crew safety by getting robots to take on tasks that could put crew members in danger. The technology also has applications in extreme and potentially dangerous environments on Earth, including disaster relief, deep-sea excavation, and maintenance of nuclear power plants. The experiment will be conducted in a pressurized environment inside the Bishop airlock, the space station’s first commercial airlock.

“This technology demonstration should show the world that the capabilities necessary for automation in space are finally available,” said Toyotaka Kozuki, the company’s chief technology officer. “It provides an inexpensive and safer source of labor in space, opening the door to true commercialization of space. “

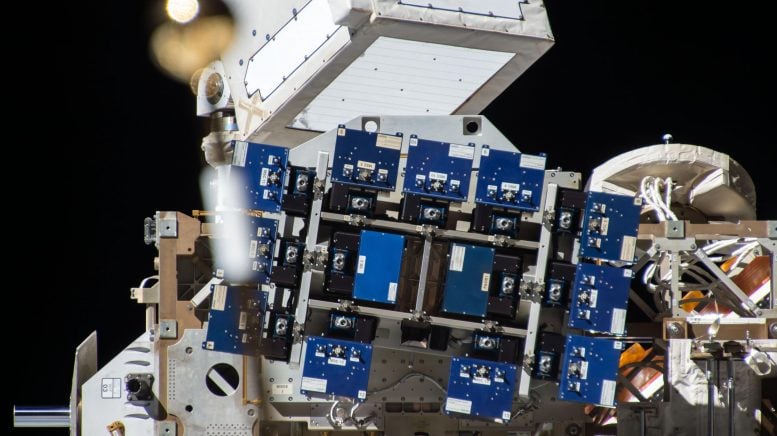

Photographic documentation of the Materials ISS Experiment Flight Facility (MISSE-FF) platform on board the International Space Station. Credit: NASA

Putting materials to the test

MISSE-15 NASA is part of a series of MISSE surveys testing how the space environment affects the performance and durability of specific materials and components. These tests provide information that supports the development of better materials for future spacecraft, spacesuits, planetary structures, and other components needed for space exploration. Testing of materials in space has the potential to dramatically accelerate their development. Materials capable of withstanding space also have potential applications in harsh environments on Earth and for better radiation protection, better solar cells, and more durable concrete. Alpha Space provides the MISSE-FF laboratory which hosts these surveys.

“MISSE-15 includes testing of concrete, spacecraft materials, fiberglass composites, thin film solar cells, radiation shielding materials, micro-optic chip, printed polymers in 3D, etc. », Said Ian Karcher, engineer of the MISSE project. “In addition, the availability of this platform for the development of commercial technologies contributes to the continued commercialization of space and the development of new space technologies. “

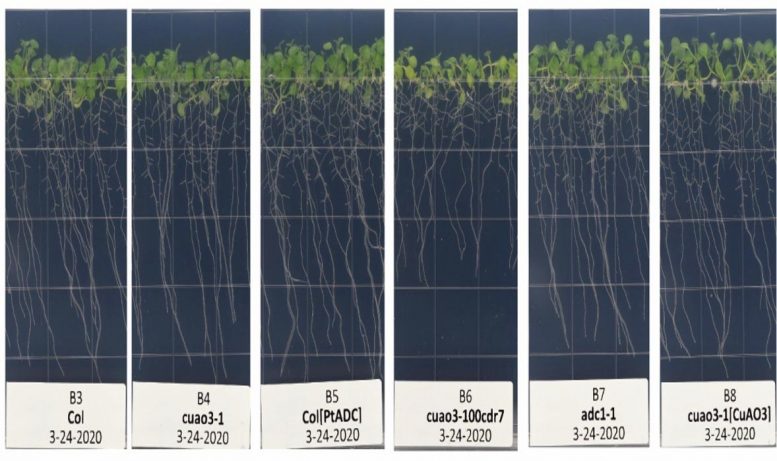

Image of seedlings with different genotypes after 9 days of growth in the VEGGIE chamber under temperature, humidity and carbon dioxide conditions mimicking those recorded on the space station. Taken during verification tests at NASA’s Kennedy Space Center. Credit: Dr Shih-Heng Su

Help plants deal with stress

Plants grown under microgravity conditions usually show signs of stress. APEX-08 examines the role of compounds known as polyamines in the thale watercress response to microgravity stress. Because the expression of genes involved in polyamine metabolism remains the same in space as in the ground, plants do not appear to use polyamines to respond to stress in microgravity. APEX-08 is trying to find a way for them to do it. The results could help identify key targets for the genetic engineering of plants more suited to microgravity.

“On Earth, polyamines have been shown to significantly contribute to the alleviation of multiple environmental stresses in plants,” said lead researcher Patrick Masson, professor at the University of Wisconsin-Madison. “Altering the metabolism of a polyamine to alleviate microgravity stress could impact our ability to use plants as key components of bioregenerative life-sustaining systems in long-term space exploration missions. It could also improve our understanding of the molecular mechanisms that allow plants to respond to general environmental stress on Earth, with impacts on agriculture, horticulture and forestry.

Easier drug delivery, Girl Scouts send science to space

The Faraday Research Facility is a multi-purpose research facility that uses the space station’s EXPRESS racks. During this first flight, the installation hosts an experiment from the Houston Methodist Research Institute and two STEM collaborations, including “Making Space for Girls” with the Girl Scouts of Citrus Council.

“The ProXopS Faraday research facility, developed in partnership with L2 Solutions Inc., is designed to operate remotely and provide a controlled environment for power, command and control, telemetry responses and security assurance. safety for microgravity experiments, ”said Chad Brinkley, president of ProXopS LLC and L2 Solution Inc.“ An added benefit of the facility is that the experiments return to the field for evaluation. ”

Faraday-NICE is testing an implantable, remote-controlled drug delivery system using sealed saline containers as surrogate test subjects. The device could provide an alternative to bulky and cumbersome infusion pumps, a possible change for the long-term management of chronic disease on Earth. Potential problems with such pumps include a high risk of infection, electromechanical failures, and double dosing. NICE is minimally invasive, implantable, has no moving mechanical components and does not require catheters. Remote administration of medication could increase patient compliance, especially for children, the elderly and people with disabilities.

Faraday-Girl Scouts set up control experiments with a Girl Scout troop and provide students with images of the same experiments in space. Studies focus on plant growth, ant colonization and the life cycle of Artemia.

[ad_2]

Source link