[ad_1]

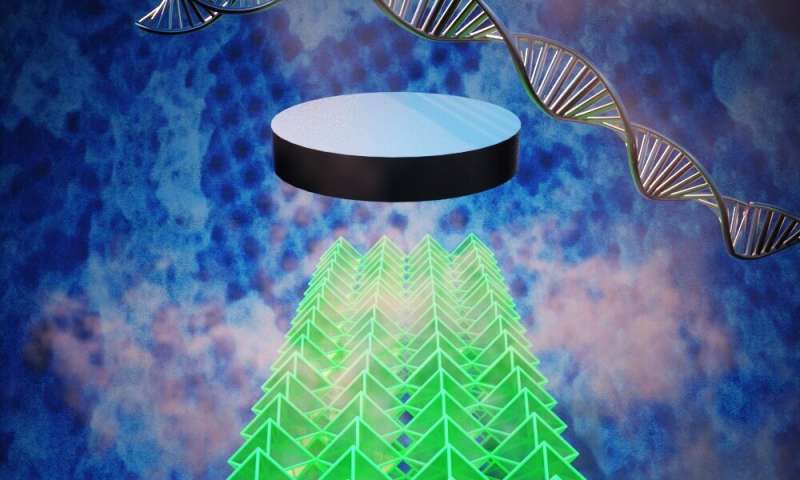

An illustration showing how highly nanostructured 3-D superconducting materials can be created based on DNA self-assembly. Credit: Brookhaven National Laboratory

Three-dimensional (3-D) nanostructured materials – those with complex shapes at a billionth of a meter size scale – that can conduct electricity without resistance could be used in a range of quantum devices. For example, such 3D superconducting nanostructures could find application in signal amplifiers to improve the speed and accuracy of quantum computers and ultra-sensitive magnetic field sensors for medical imaging and underground geological mapping. However, traditional manufacturing tools such as lithography have been limited to 1-D and 2-D nanostructures like superconducting wires and thin films.

Now, scientists from the Brookhaven National Laboratory of the United States Department of Energy (DOE), Columbia University and Bar-Ilan University in Israel have developed a platform to create 3D superconducting nano-architectures with a prescribed organization. As reported in the November 10 issue of Communications of nature, this platform is based on the self-assembly of DNA into desired 3D shapes at the nanoscale. In DNA self-assembly, a single long strand of DNA is folded by complementary shorter “base” strands at specific locations – similar to origami, the Japanese art of paper folding.

“Due to its structural programmability, DNA can provide an assembly platform for the construction of engineered nanostructures,” said co-correspondent author Oleg Gang, leader of the Soft and Bio Nanomaterials group at Brookhaven Lab’s Center for Functional Nanomaterials (CFN) and Professor of Engineering Chemistry and Applied Physics and Materials Science at Columbia Engineering. “However, the fragility of DNA makes it unsuitable for the fabrication of functional devices and for nanofabrication requiring inorganic materials. In this study, we have shown how DNA can serve as a scaffold for the construction of nanoscale architectures. 3D which can be fully “converted” to inorganic materials such as superconductors. “

To make the scaffolding, scientists at Brookhaven and Columbia Engineering first designed octahedral-shaped DNA origami “frames”. Gang graduate student Aaron Michelson applied a DNA-programmable strategy to make these frames fit into desired lattices. Next, he used a chemistry technique to coat the DNA arrays with silicon dioxide (silica), solidifying the originally soft constructs, which required a liquid environment to preserve their structure. The team adapted the manufacturing process so that the structures were true to their design, as confirmed by imaging at the CFN electron microscopy facility and small-angle x-ray scattering at the beamline. Diffusion of Complex Materials from the Brookhaven Synchrotron II Light Source (NSLS-II). These experiments demonstrated that structural integrity was preserved after coating the DNA arrays.

“In its original form, DNA is completely unusable to be processed with conventional nanotechnology methods,” Gang said. “But once we coat DNA with silica, we have a mechanically robust 3-D architecture on which we can deposit inorganic materials using these methods. This is analogous to traditional nanofabrication, in which valuable materials are deposited on flat substrates, usually silicon, to add functionality. “

The team shipped the silica-coated DNA arrays from the CFN to the Bar-Ilan Institute for Superconductivity, led by Yosi Yeshurun. Gang and Yeshurun got to know each other a few years ago, when Gang gave a seminar on his DNA assembly research. Yeshurun - who for the past decade has studied the properties of nanoscale superconductivity – believed Gang’s DNA-based approach could provide a solution to a problem he was trying to solve: how can we make three-dimensional superconducting nanoscale structures?

“Previously, manufacturing 3D nanosuperconductors involved a very elaborate and difficult process using conventional manufacturing techniques,” said Yeshurun, corresponding co-author. “Here we have found a relatively easy way to use Oleg’s DNA structures.”

At the Institute of Superconductivity, Yeshurun graduate student Lior Shani evaporated a low-temperature superconductor (niobium) onto a silicon chip containing a small sample of the arrays. The evaporation rate and temperature of the silicon substrate had to be carefully controlled so that the niobium covers the sample but does not penetrate completely. If this were to occur, a short circuit could occur between the electrodes used for electronic transport measurements.

“We cut a special channel in the substrate to make sure that current would only flow through the sample itself,” Yeshurun explained.

The measurements revealed a three-dimensional network of Josephson junctions, or thin non-superconducting barriers through which superconducting current passes through tunnels. Josephson junction networks are essential for taking advantage of quantum phenomena in practical technologies, such as superconducting quantum interference devices for magnetic field detection. In 3-D, more junctions can be grouped together in a small volume, thus increasing the power of the device.

“DNA origami has produced beautiful and ornate 3D nanoscale structures for nearly 15 years, but DNA itself is not necessarily a useful functional material,” said Evan Runnerstrom, Head of the Design Program. materials at the US Army Combat Capabilities Development Command Army Research Laboratory of the US Army Research Office, which partially funded the work. “What Professor Gang has shown here is that you can use DNA origami as a model to create useful 3D nanostructures of functional materials, like superconducting niobium. This ability to arbitrarily design and manufacture functional materials. 3D-structured complexes from the bottom up will accelerate the military’s modernization efforts in areas such as sensing, optics and quantum computing. “

“We have shown how complex DNA organizations can be used to create highly nanostructured 3-D superconducting materials,” Gang said. “This route of material conversion gives us the ability to fabricate a variety of systems with interesting properties – not only superconductivity, but also other electronic, mechanical, optical and catalytic properties. We can think of it as a” lithography molecular “, where the power of DNA programmability is transferred to inorganic 3-D nanofabrication.”

Nano-objects of desire: assembling ordered 3-D nanostructures

Nature’s communications (2020). DOI: 10.1038 / s41467-020-19439-9

Provided by Brookhaven National Laboratory

Quote: Making 3-D nanosuperconductors with DNA (2020, November 10) retrieved November 10, 2020 from https://phys.org/news/2020-11-d-nanosuperconductors-dna.html

This document is subject to copyright. Apart from any fair use for study or private research, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link