[ad_1]

-

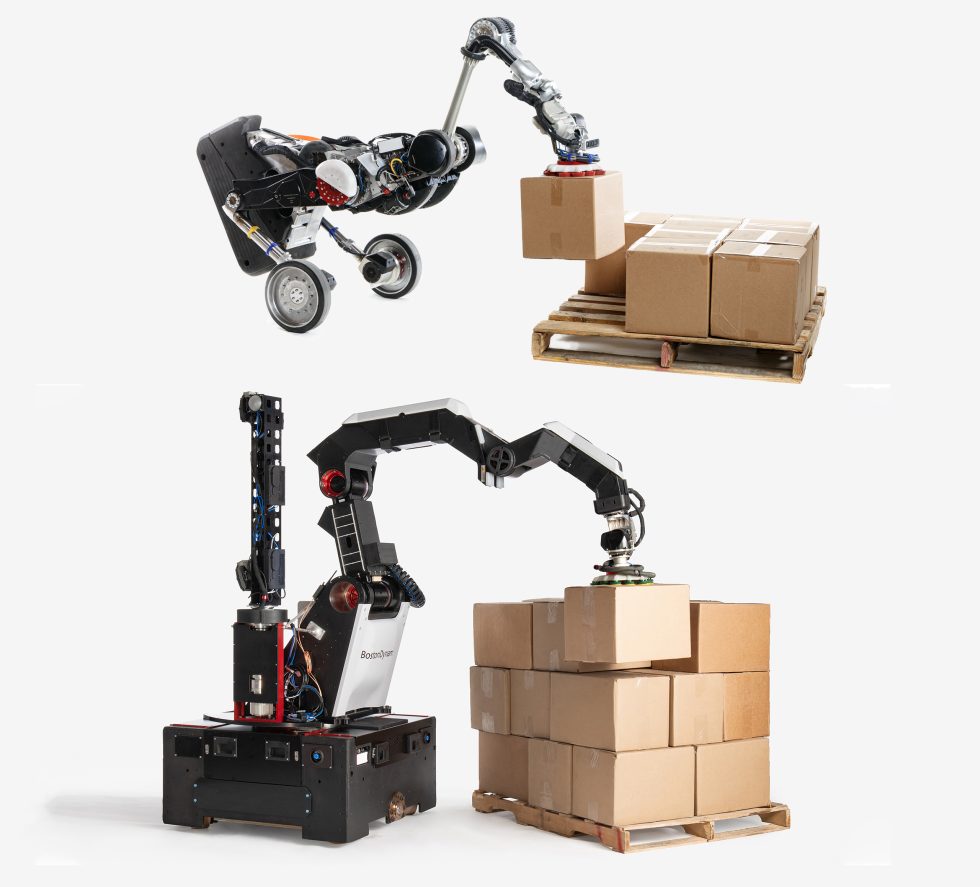

Stretch is a mobile box moving robot, with a strong arm and a large mobile base.

-

The base is the same size as a pallet, so it can fit anywhere a pallet fits.

-

Stretch’s additional arm joints allow it to reach the top of the truck.

-

Stretch, in its compact folded fashion.

After 28 years of research and development, Boston Dynamics entered the trading robot market last year with the launch of Spot. He’s a roughly $ 75,000 robotic dog that can walk around facilities for remote inspections and, with an extra arm, can even open doors and perform manipulations from a distance.

Today, Boston Dynamics’ quest to market continues with the announcement of a second commercial robot, “Stretch,” a box moving robot designed to meet the demands of warehouses and distribution centers. The robot is designed to “go where the work is” in a warehouse, unloading trucks, unpacking shipments and eventually placing orders. For now, we’re seeing a prototype, but Boston Dynamics is hoping companies will start buying Stretch when it goes into commercial deployment in 2022.

As Kevin Blankespoor, vice president of product engineering at Boston Dynamics, told us, shortly before Stretch launched, the company is going to where the customers are. “When we released our first ‘Next-gen’ Atlas video,” said Blankespoor, “there was a portion of that video that showed the Atlas moving boxes, and we had a great reaction from the folks over. warehouse. They wanted Atlas to come and work in their warehouse. “Atlas is the company’s all-purpose humanoid research robot and it’s probably way too expensive to be a commercial product.

Blankespoor continues: “We were like, ‘Well, Atlas is probably a little complicated to work in a warehouse, but we could design a much simpler robot that has the same attributes. “” The result was not just a new robot. , but an entire warehouse-focused division within Boston Dynamics, led by Blankespoor.

Master the stretch

With a clear demand for warehouse robots, Boston Dynamics began to experiment, first with its “Handle” robot. The grip started life around a new “wheeled-leg” mobility platform – two-legged, but with wheels at the bottom instead of feet, allowing all manner of nimble movements. The first version of Handle was a humanoid robot capable of doing all kinds of crazy tricks thanks to its wheel legs, like turning around corners, going down stairs, and jumping on a table. The video shows Handle lifting a box with its two humanoid arms, but the robot was not yet intended for warehouse work.

For version 2, Handle was “re-imagined” of what looked like a stunt robot in a warehouse robot, and instead of two arms, he used a large vacuum gripper to lift the boxes. The grip still used the wheel-leg concept, but now with a big counterweight in the back, and with the long “neck” that supported the vacuum gripper up front, it looked more like a bird. Blankespoor says that Handle could cover many use cases of Atlas in a warehouse, but with a third of seals.

With Handle, Boston Dynamics went so far as to experiment with customers. The warehouse work shown in the Handle version 2 video showed the robot loading and unloading a pallet in a large open space, and Handle was good at it. The problem with Handle is that sometimes warehouse work has to happen in a confined space, like unloading a truck, and this is where the robot had problems.

Boston Dynamics / Ron Amadeo

“It became clear that for Handle, maneuvering in a tight space was tricky,” Blankespoor explained. “We could do the job and unload all the boxes, but it was taking too long, basically. Whenever Handle picked up a box, it had to back up to the middle of the truck so it could turn without collision, move forward, and place the box. “When lifting boxes, the handle kept its balance with a big swinging counterweight in the back, and it seemed like the robot’s big bird butt was constantly in the way.” We knew there was that other option there. -low, “Blankespoor said.” We’ve been considering something like Stretch for years. “

Boston Dynamics

Stretch is Boston Dynamics’ first “made-for-the-warehouse” robot, and you can see that much of the bird’s agile design has been discarded in favor of a large, massive industrial robot. We’ll start with the basics: the robot is simply mounted on a large box now, so it’s stable by default and doesn’t have to actively balance itself anymore. The robot now weighs 1,200 kg (2,650 lbs), so there is no need for a large oscillating counterweight when lifting – it will not tip over. The arm can rotate on top of the base, allowing it to unload boxes from a truck onto a conveyor belt without the need to move around and bump into something. The result is that Stretch can unload a truck about five times faster than Handle. Stretch can move up to 800 boxes per hour.

Most warehouses are designed around the 48 x 40 inch dimensions of a pallet, so the Stretch base has just a 48 x 40 inch footprint and can fit anywhere a pallet fits. The wheels in each corner of the box, all with independent steering, allow Stretch to move in any direction, including side-to-side or spinning in place. The giant base also means there’s plenty of room for the battery, enough to power Stretch for an eight-hour shift, or up to 16 hours with the “extended runtime option”.

Go where the work is

There are many stationary robot arms that can move boxes, but fixed-frame arms require expensive installation, and you need them for every location a box needs to be moved. Being mobile means Stretch can do the job of multiple stationary arms as needed in the warehouse, without the need to redesign or install anything. Blankespoor imagines a typical day in the warehouse for Stretch: “Stretch could spend the morning on the inbound side of the warehouse unloading the boxes from the trucks. He could spend the afternoon in the warehouse aisles building pallets – these will go to retailers or ecommerce centers. And he could spend the evening putting boxes back in trucks. “

Stationary arms can be as beefy as you need, but being mobile means Stretch has to watch your weight. Boston Dynamics’ custom arm design is a quarter of the weight of an industrial arm, while still being able to outperform its predecessor, with a maximum payload of 50 pounds (23 kg) compared to the capacity of 33 pounds (15 kg) of Manage. The arm had to be designed so that it could reach the pallets and boxes at the very top of the truck, where there won’t be much clearance. The robot actually grabs the top row of boxes from the side, as it won’t be able to fit between the box and the roof.

Boston Dynamics / Ron Amadeo

The last major component of Stretch is the Perception Mast, a tall tower that sits on the same rotating base as the arm and houses most of the robot’s sensors, so it never gets in the way of the arm. The mast houses both 2D and depth sensors, giving Stretch a top view of its surroundings. For vision, the robot uses Boston Dynamics’ “Pick” software, a collection of algorithms based on machine learning to detect and move boxes, which arrived at the company through an acquisition of Kinema Systems.

Stretch’s base actually has a modular interface where you can attach various accessories. For unloading the truck, you can attach a conveyor belt to Stretch, so that the robot can take the conveyor belt with it as it sinks deeper into the truck. This means just pick up a box, spin it around and drop it for faster unloading. There is also a pallet cart attachment, so the robot can carry a pallet while it is building orders. Additional sensors can also be attached to the base, either for situational awareness like additional cameras or lidar, or a barcode reader for entry.

Boston Dynamics hopes to sell Stretch in 2022, but it still has a few iterations to do before then. What we are currently seeing is the Stretch prototype, while the “produced” version of Stretch will be sold next year. As Blankespoor explains, “The Stretch product will look a lot like this, but it has really been completely redesigned from the ground up. Each component has been reworked for manufacturability in order to reduce costs, reliability and better performance. So the Stretch product, we’re going to start by building the first units this summer, and then it will go on sale next year. We will begin to deploy applications that the product can do, gradually. The first one we will do is unload the trucks, and then a little bit later we will start building pallets. Blankespoor says the end product will get a few more sensors, like a lidar on the robot’s face.

“The other thing with the prototype is that our entire software team gets off to a good start in developing control systems, vision and autonomy, and testing it on real hardware,” Blankespoor tells us, “so that when you get the product, the systems are a lot more mature. “

[ad_2]

Source link