[ad_1]

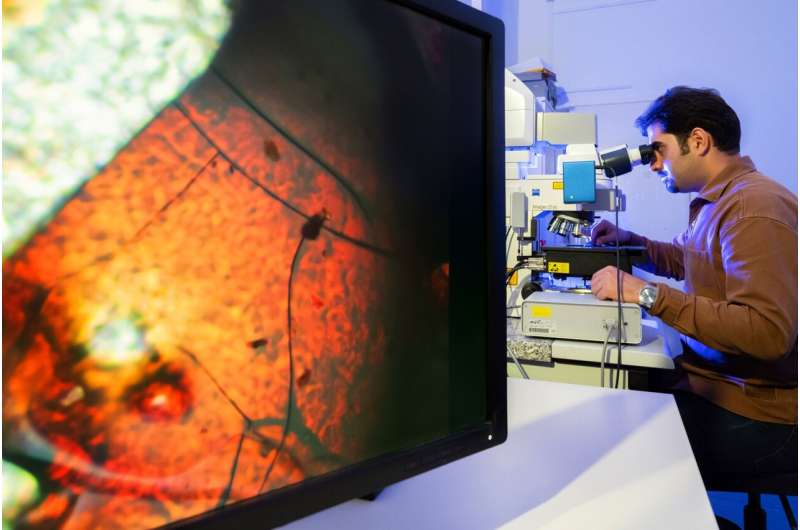

Vahid Nozari of the University of Jena uses a microscope to examine the new synthetic glass, which is made of a non-fusible metal-organic compound (MOF). Credit: Jens Meyer / University of Jena

Glasses are an essential part of everyday life. One of the most important reasons for this is that glassware can be made almost universally and inexpensively in a wide variety of shapes and sizes using their corresponding castings. The liquid phase (viscous) treatment offers versatility that is difficult to achieve with other materials. However, this presupposes that the material from which glass is made in terms of chemical composition can be melted.

The so-called organo-metallic framework compounds, abbreviated MOF, have aroused a great deal of interest in recent years. Due to their special properties, they are considered to have great potential for future applications in energy and environmental technologies, but also as sensor components and in the biological and life sciences. For example, MOFs can be used as raw materials for membrane filters for gas separation in technical combustion processes or for water treatment. The basis for the multitude of possible applications is above all an exceptional property of MOFs: their high and largely controllable porosity. MOF substances are made up of inorganic particles joined by organic molecules to form a network of pores. As MOFs are mainly in powder form, one of the main challenges in the field is to produce components in bulk. This is where the glasses come in.

Trade-off between properties and processability

But with a few exceptions, the porosity of all things prevents the materials from being fusible and therefore transformable into components of the desired shape. Chemists at Friedrich Schiller University in Jena, Germany, and Cambridge University, UK, have now found a solution to this problem. They report their research results in the current issue of Nature Communication.

In order to produce components for industrial applications from MOF, they can be transformed into so-called hybrid glasses, for example. To do this, however, you have to melt them down – a process which is not straightforward in this specific case. So far, only a handful of candidates from this class of substances have been shown to melt. “In most of the known MOF materials, the high porosity is one of the reasons why, on heating, they thermally decompose before reaching their melting point, that is, they burn” , explains Vahid Nozari, doctoral student at the Laboratory of Glass Sciences at the University of Jena. It is precisely the property that makes these materials so interesting that also prevents them from being processed by the glass route.

Identification of combinations of ionic liquids, MOF matrices and melting conditions

So how do you melt a non-fusible material to shape it and process it to a liquid state? The team led by Professor Jena Lothar Wondraczek has now found an answer to this question. “We filled the pores with an ionic liquid which stabilizes the internal surface so that the substance can finally melt before it even breaks down,” explains Wondraczek. The researchers were able to show how the normally non-fusible substances of the MOF family of zeolite imidazolate (ZIF) frames can effectively be converted to a liquid state and, finally, a glass. “In this way, the desired component can be obtained, for example, in the form of a membrane or a disc. The residues of the ionic liquid used can then be washed after shaping.”

The key to future applications lies in the interactions between the ionic liquid and the MOF material. These determine the reversibility of the process, i.e. the possibility of washing the auxiliary liquid after the melting process. If the reactions are not suitable, either the pore surface is not sufficiently stabilized or there is an irreversible chemical bond between the MOF and parts of the ionic liquid. Therefore, the ideal combinations of liquids, matrix materials and melting conditions must be identified in view of the desired application, so that large volume objects become possible.

New glass materials made from organic and inorganic components

Vahid Nozari et al, Ionic liquid facilitated the fusion of the ZIF-8 metallo-organic framework, Nature Communication (2021). DOI: 10.1038 / s41467-021-25970-0

Provided by Friedrich Schiller University in Jena

Quote: Fusion of glasses from infusible compounds (2021, September 29) retrieved September 30, 2021 from https://phys.org/news/2021-09-glasses-unmeltable-compounds.html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link