[ad_1]

In the years to come, astronauts will return to the moon for the first time since the closure of the Apollo era. Beyond that, NASA and other space agencies plan to put in place the necessary infrastructure to maintain a human presence there. This will include the Orbiting Artemis Gateway (formerly the Lunar Gateway) and surface bases, such as NASA’s Artemis Base Camp and ESA’s International Lunar Village.

This presents a number of challenges. The Moon is an airless body, it experiences extreme temperature variations, and its surface is exposed to much more radiation than we experience here on Earth. On top of that, there’s moon dust (aka. Regolith), a fine powder that sticks to everything. To solve this particular problem, a team of researchers led by ESA is developing materials that will provide better protection for lunar explorers.

During the Apollo missions, moon dust was the greatest operational concern of astronauts. Within days of their exposure, their spacesuits suffered from obscured visors, clogged mechanisms, and erosion in the layers of their suits. This stems from the special nature of the lunar regolith, which is jagged, extremely thin, and electrostatically charged (which causes it to adhere to surfaces).

Origins of moon dust

Since the Moon is an airless body and does not experience any precipitation, the regolith on its surface has not benefited from geological processes (wind and water erosion) that would smooth it out over time. As a result, billions of years of micrometeorite bombardment pulverized much of the surface into fine particles with razor-sharp edges.

During this time, the sun’s rays (which are not filtered by an atmosphere) give the dust a significant static charge. As ESA structural engineer Shumit Das explains in a recent ESA press release:

“Depending on its area of origin, dust can have very different chemical and abrasive characteristics, with its precise properties depending on the landing site chosen – which is another factor of concern.

“One of Apollo’s main conclusions was that the abrasion effects of the lunar regolith would be the main limiting factor in returning to the moon. We want to overcome that and activate spacesuits that could be used for many more spacewalks than the few walks that an Apollo landing does – up to 2,500 hours of surface activity is our guess.

Hazardous material

When the Apollo missions took place, astronauts discovered that regolith was a constant problem during extra-vehicular activities (EVA) and also had great difficulty keeping it out of their Apollo Lunar Modules (ALMs). In addition to being dangerous for the suits and equipment of astronauts, lunar regolith also poses a serious risk to the health of astronauts.

In a 2005 NASA study, reports from the six Apollo missions were studied to assess the overall effects of moon dust on EVA systems. Ultimately, they concluded that the most significant risks included “dimming of vision, false instrument readings, coating with dust and contamination, loss of traction, clogging of mechanisms, abrasion, thermal control issues, seal failures, and inhalation and irritation. ”

There are also volumes of anecdotal evidence from Apollo astronauts that point to how much of a danger moon dust was during landings. After returning from the Apollo 11 mission, Neil Armstrong described what it was like trying to land the Eagle Lander module:

“At less than 100 feet we start to get a transparent sheet of moving dust that obscures visibility a bit. As we descended the visibility continued to decline. “

Pete Conrad, the commander of the Apollo 12 mission, characterized moon dust as follows:

“I think one of the most aggravating and restrictive facets of exploring the lunar surface is the dust and its adhesion to everything, regardless of the type of material, be it skin, body material. suit, metal, whatever it is and its restrictive friction. – as an action to everything he does. “

“The integrity of the suits remained good, but there is no doubt in my mind that with a few more EVAs something could have stopped. In the area where the lunar boots went up over the suits, we wore through the outer garment and started to wear through the Mylar.

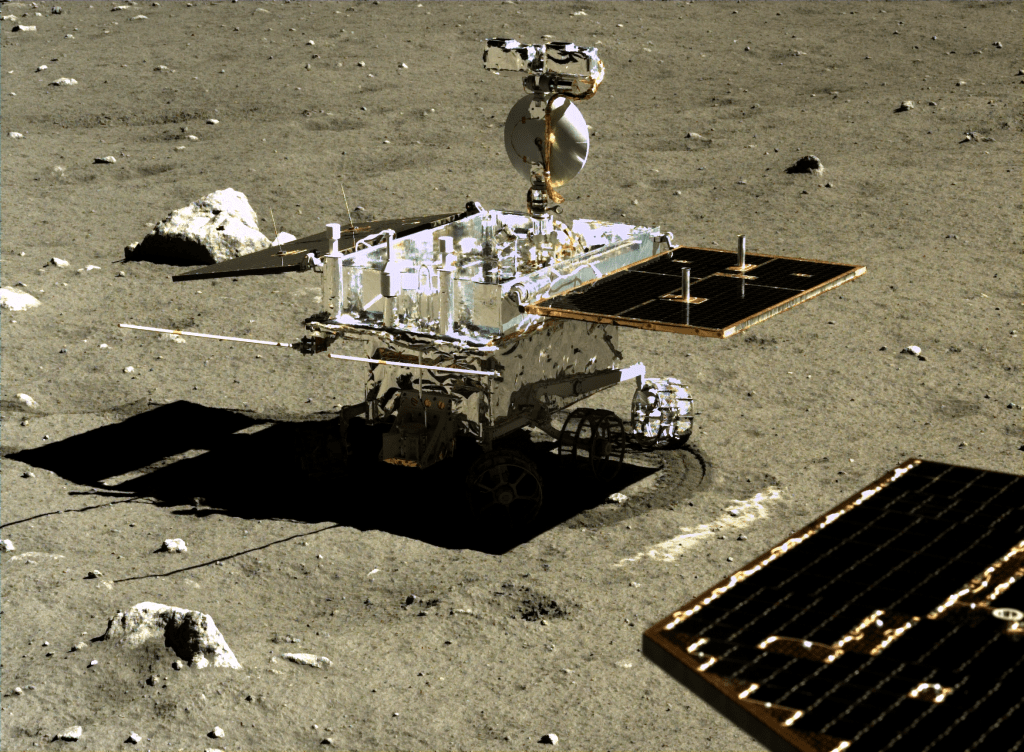

Lunar regolith is also dangerous for machines, as demonstrated by the Chinese rover Yutu-1, which came to rest on the surface during its second day of operations (January 11, 2014). While the situation was resolved and the rover continued to operate for several months, Chinese authorities reported that the rover had “suffered a malfunction in the control circuit of its control unit”, believed to be due to the penetration of dust inside.

Depending on where dust is coming from on the Moon, it can have very different chemical and abrasive characteristics. Knowing the precise properties of moon dust at a specific location is therefore essential when it comes to choosing a landing site. As ESA structural engineer Shumit Das explains:

“One of Apollo’s main conclusions was that the abrasion effects of the lunar regolith would be the main limiting factor in returning to the moon. We want to overcome that and activate spacesuits that could be used for a lot more spacewalks than the few walks done by Apollo landing – up to 2,500 hours of surface activity is our guess.

Testing of new materials

Drawing its inspiration from the Apollo missions, ESA joined forces with the French developer of innovation and technology Comex, the German textile and fiber research institutes and the citizen science organization the Space Forum Austrian to develop new materials capable of withstanding the lunar environment. As Malgorzata Holynska, ESA Materials and Process Engineer, said in a recent ESA press release:

“The idea came up that when ESA returns to the Moon, we should look at harnessing the many innovations in materials since the design of the Apollo spacesuits over half a century ago. .

“So while we are not developing a new spacesuit at this time, we are looking to select candidate materials that such a suit could use – as well as protective covers for rovers or fixed machinery and infrastructure – and to perform advanced items. tests to see how they withstand simulated lunar conditions, especially moon dust. “

Last year, ESA held a workshop where different material suppliers were able to come together to discuss possible options based on the most recent advances. Eventually it was decided that a layered solution should be adopted as no material can do the job on its own. The only remaining issues are which combination of functional layers works best and what is the best way to connect them?

“We then test these different batteries against criteria provided by our colleagues at ESA’s Directorate of Robotic and Human Exploration,” added Holynska. “The challenge here is to make the tests as robust as possible, to come up with credible results to guide our choice of compromise and selection down.”

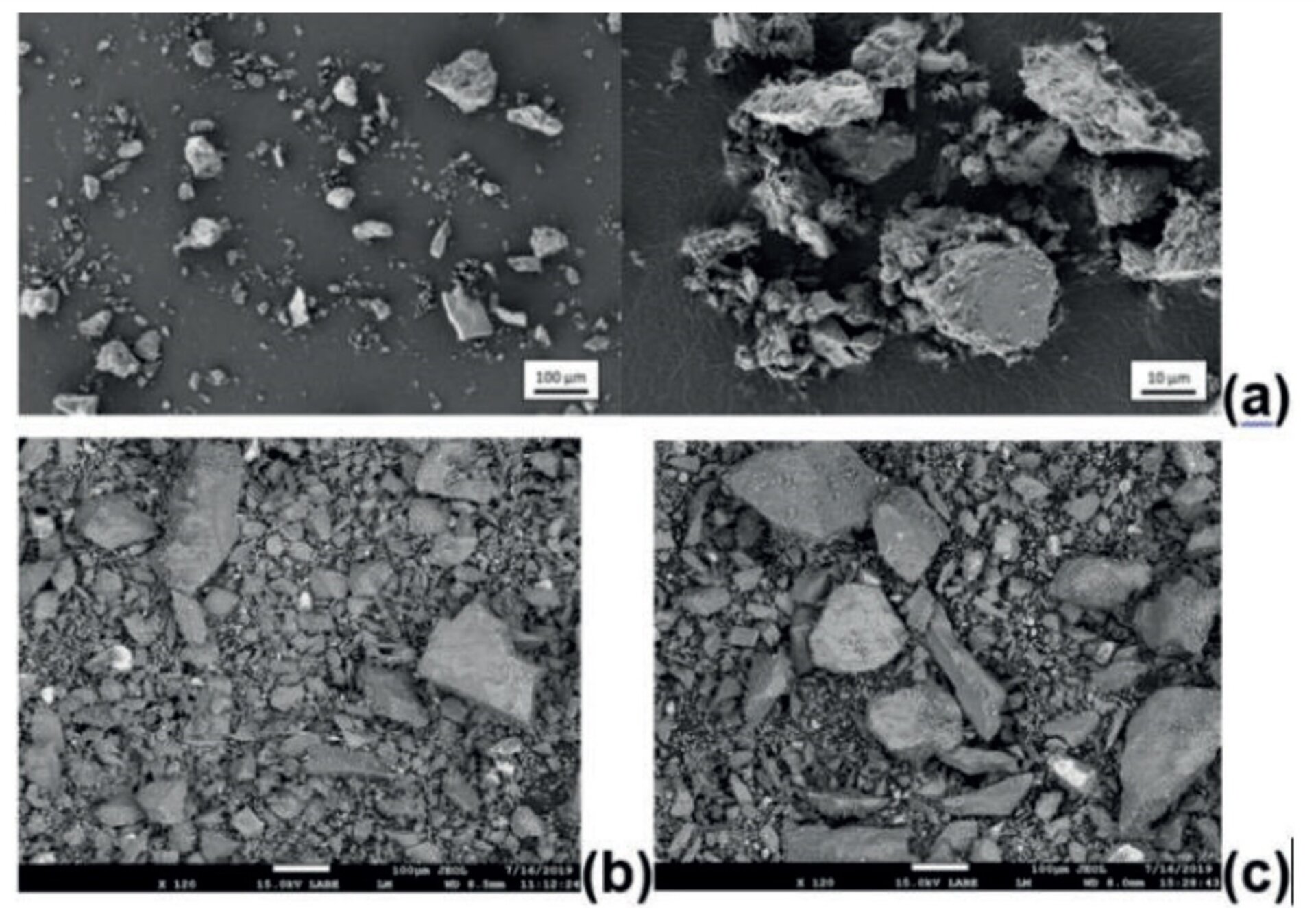

The DITF performs most of the project testing. This includes abrasion testing, where a sample of the material is placed in a beaker with bricks of simulated lunar regolith to see how it handles physical and chemical interactions. The simulated regolith (called EAC-1A) was created from volcanic soil and was provided by ESA’s European Astronaut Center in Germany.

Then there are the usual permeability tests, where a high pressure fluid is applied to samples of material to see if it penetrates the fibers. A thermal cycling test chamber is also being developed which will expose the material to extreme temperature and vacuum conditions. The testing regime is varied so that it can examine the entire life cycle of future space suits, from storage to use for spacewalks. Shumit explains:

“Future suits would generally be stored on the lunar orbiting gateway between surface EVAs. We need to know that gaskets, rubber or other parts of the suits will not be degraded by storage time, which also includes accelerated aging tests including exposure to moisture and radiation.

In 2024, NASA will send astronauts to the moon with the Artemis III mission. By 2028, they plan to have completed assembly of the Orbiting Artemis Gateway and Surface Artemis Base Camp, creating a “sustainable lunar exploration program.” ESA is a key partner in these efforts and also plans to build a lunar base that will be a “successor to the ISS”.

In order to spend long periods of time living, working, and exploring, astronauts will need all the technology, equipment, and infrastructure they need to stay safe in lunar conditions. A key element in all of this is the space suits that astronauts will wear during EVAs, which will be their only protection against the elements and all the natural hazards of the Moon.

This project is supported by ESA’s Technology Development Element (TDE), a compulsory program that supports all areas of ESA activity. It was also the subject of a study conducted by Comex researchers which was presented in the journal Advanced Materials Technologies – titled “Advanced Materials for Future Lunar Extravehicular Activity Space Suit”

Further reading: ESA

[ad_2]

Source link