[ad_1]

Researchers from University of Illinois at Chicago (UIC) developed a 3D bioprinting process without scaffolding.

Generally, biodegradable scaffolds are used to retain the shape of a bio-printed 3D tissue used in research in regenerative medicine. However, according to the study Posted in Horizons Materials, by-products of degradation in scaffolds can be toxic as well as iinterfere with the development of connections between functional tissue cells.

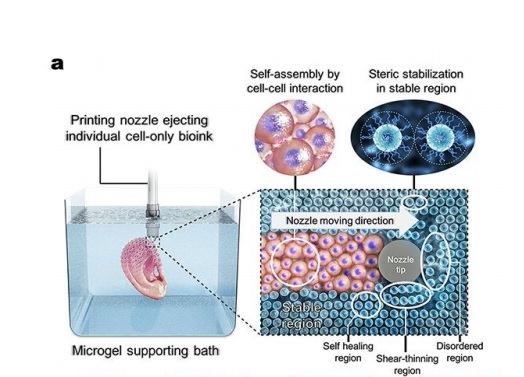

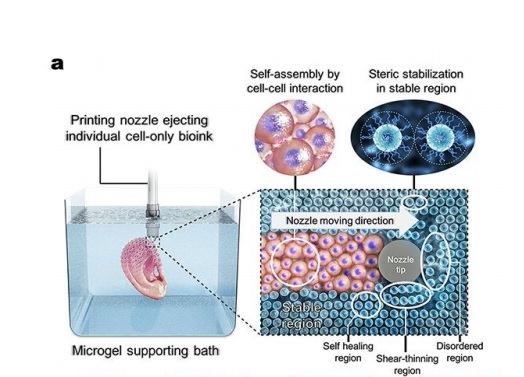

Ay UIC, a microgel support bath was created to allow the free flow of a print nozzle for the extrusion of high resolution cells. Eben Alsberg, Professor Richard and Loan Hill of Bioengineering and Orthopedics, UIC, has explained:

"Our unique cell-only printing platform enables 3D cell-free scaffolding without conventional scaffolding with the help of a temporary hydrogel ballbath." in which the printing takes place. "

"For the first time, only cell constructs can be printed in complex forms composed of different cell types without hydrogel support or traditional scaffolding, which can then be stabilized for a period of one day to several weeks. "

A bath of hydrogel beads

As part of the UIC research, micron hydrogel beads make up a bath to allow a 3D bioprinter nozzle to move and deposit cells in place while preserving their shape. These cells are exposed to ultraviolet light, which cross-links or "freezes" the beads, allowing them to mature and grow in a stable structure.

"The hydrogel bead bath has unique properties that allow both the printing of cells bioink only in complex architectures and the resulting temporary stabilization," added Professor Alsberg. "By using chemistry, we can then adjust the moment when the pearls disappear."

With the hydrogel beads bath, the UIC team used stem cells to 3D print an ear-shaped cartilage and a waist-size femur. a rodent, forming stable cell-to-cell connections through specialized proteins.

Through the use of a sacrificial carrier gel, the method has some similarities to FluidForm's FRESH 3D biotyping methodology and microfluidic chip fabrication by Harvard University's Lewis Lab.

3D reprinting of large functional tissues

Although 3D bioimpression with scaffolds provides support for the underlying architecture of an organ or tissue by seeding cells, the decomposition of a scaffold can be difficult to synchronize at the same time as the maturation of said organ or tissue.

Following the success encountered with 3D bioprint cartilage and femur, Professor Alsberg said, "We have demonstrated that individual cells and cell aggregates can be organized and assembled using this platform strategy so to form larger functional tissues. "for tissue engineering, drug screening and as models for studying developmental biology.

«Specific biocellular and photocurable support for individual cells for 3D printing and the generation of technical fabrics with complex geometries» is co-written by Oju Jeon, Yu Bin Lee, Jin Lee Sang, Derrick Wells, Hyeon Jeong and Eben Alsberg.

Want the latest news on additive manufacturing? Subscribe to the Bulletin of the 3D Printing Industry and follow us on Twitter and Facebook.

Looking for a career in additive manufacturing? Visit 3D printing works for a selection of roles in the industry.

The clip presented shows the process of bioimpressing the letter "C" using a stem cell only "bioink" in an alginate microbead carrier. Clip via Oju Jeon and Eben Alsberg / UIC.

[ad_2]

Source link