[ad_1]

In order to achieve batteries for electric vehicles with greater autonomy, the German Federal Ministry of Economic Affairs and Energy created the project EMBATT-going FAB, involving four German companies and institutions: Daimler, Thyssenkrupp System Engineering, IAV and the Fraunhofer Institute for Ceramic Technology and Systems. For two years, the four partners will develop bipolar batteries with greater storage capacity than current ones. According to the developers, these battery cells applied to the electric car could offer up to 1000 kilometers of autonomy per charge.

The goal is to advance the industrialization of so-called bipolar batteries by seeking large-scale manufacturing techniques and integration options, once the first stage of the project has been successfully completed.

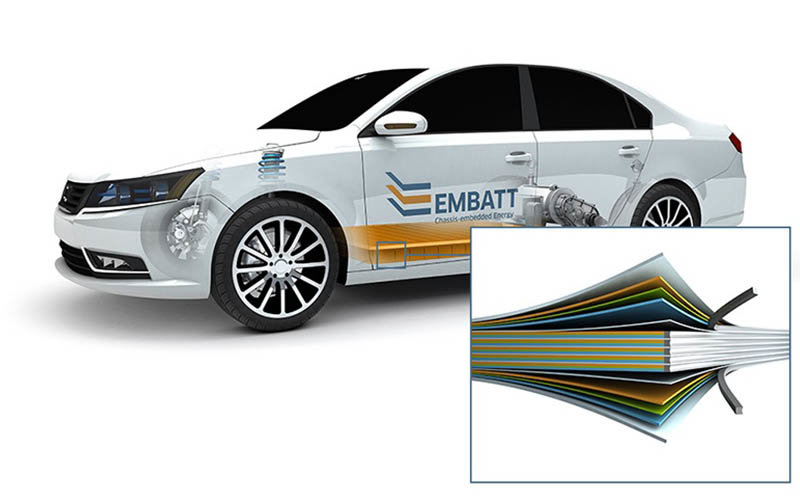

EMBATT bipolar battery 20×30 cm.

Bipolar lithium-ion batteries, such as fuel cells, consist of electrodes stacked and interconnected in series. Unlike conventional lithium-ion batteries, the electrodes are bipolar: the active materials for the cathode and, on the other hand, the active materials for the anode, are attached to a common electrode holder. Individual lithium-ion cells are not packaged separately side by side in small aluminum housings, but once the electrode stack is complete, they are packaged in a big common shell.

This eliminates the necessary components to contain each of the packages and connection elements, save costs and free up space which is used to include more active material. As a result, the bipolar lithium-ion battery can store more energy and increase the vehicle's range.

Internal structure of the battery by the Fraunhofer Institute.

The expected duration of the project is two years. The partners will meet several challenges depending on the skills of each. The Frahunhofer Institute will be responsible for electrode production bipolar Upgrades using oxides of lithium, nickel, manganese, cobalt and graphite as storage materials. His research has already developed a prototype first bipolar electrode, pilot scale, in the form of metal tape coated on both sides of ceramic materials, so that one of them is the first one. between them performs the functions of cathode and the other anode.

The scaling technology Assembly up to a size of 1000×30 cm2 will be provided by Thyssenkrupp System Engineering. The system of battery monitoring is responsible for the BTI and finally the security simulations to meet the specific requirements of the vehicle will be made by the automotive group Daimler.

[ad_2]

Source link