[ad_1]

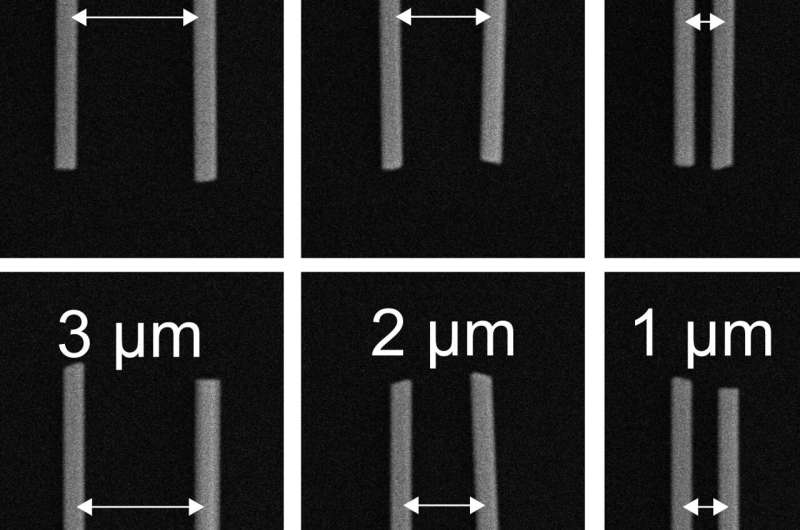

Researchers have developed a new way to assemble multiple nanoscale optical devices extremely close to each other on a single chip. They demonstrated the transfer printing method by placing nanotubes of 1 to 3 microns. Credit: Dimitars Jevtics, University of Strathclyde

Researchers have developed a very precise way to assemble multiple micron-scale optical devices extremely close to each other on a single chip. The new approach could one day enable high volume fabrication of chip-based optical systems that would enable more compact optical communication devices and advanced imagers.

“The development of electronics based on silicon transistors has enabled increasingly powerful and flexible systems on a chip,” said Dimitars Jevtics of the University of Strathclyde in the UK. “Optical systems on a chip, however, require the integration of different materials on a single chip and, therefore, have not seen the same scale development as silicon electronics.”

In the Optica Publishing Group review Optical materials Express, Jevtics and colleagues describe their new transfer printing process and demonstrate its ability to place devices made up of multiple materials on a single chip, all embedded in a footprint similar in size to the devices themselves. While other methods are generally limited to a single material, this new approach provides a material toolbox that future system designers can draw upon.

“Optical on-chip communications, for example, will require the assembly of optical sources, channels and detectors on subassemblies that can be integrated with silicon chips,” Jevtics said. “Our transfer printing process could be extended to incorporate thousands of devices made from different materials on a single wafer. This would allow the integration of optical devices at the micron scale in future computer chips for high density communications or in a laboratory on a bio-detection platform of chips. ”

A better way to choose and place

One of the biggest challenges in assembling multiple devices on a chip is trying to place them very close to each other without disturbing devices already on the chip. To do this, researchers have developed a method based on reversible adhesion in which a device is taken and released from its growth substrate and placed on a new surface.

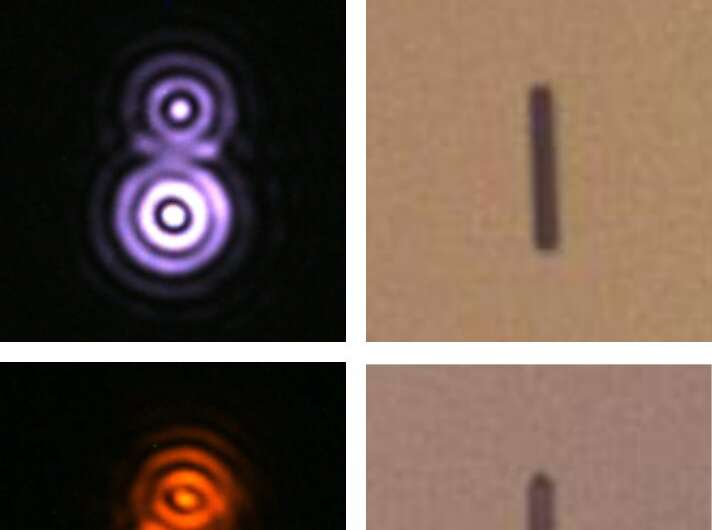

The researchers also created a multi-wavelength nanolaser system by placing semiconductor nanowires on silicon dioxide. The new method of transfer printing could one day allow the manufacture in large volumes of optical systems based on chips made of several materials. Credit: Dimitars Jevtics, University of Strathclyde

The new method uses a flexible polymer pad mounted on a robotic motion control stage to pick up an optical device from the substrate on which it was fabricated. The substrate on which it will be placed is then positioned under the suspended device and precisely aligned using a microscope. When properly aligned, the two surfaces are brought into contact, freeing the device from the polymer pad and depositing it on the target surface. Advances in precise micro-assembly robotics, nanofabrication techniques and microscopic image processing have made this approach possible.

“By carefully designing the geometry of the pad to match the device and controlling the adhesion of the polymeric material, we can determine whether a device will be recovered or released,” Jevtics said. “Once optimized, this process is harmless and can be extended using automation to be compatible with wafer-scale manufacturing.”

Creating a densely packed chip

To demonstrate the new technique, the researchers integrated gallium aluminum arsenide, diamond and gallium nitride optical resonators on a single chip. These optical resonators exhibited good optical transmission, demonstrating that the integration was working well.

They also used the printing approach to create semiconductor nanowire lasers by placing nanowires on host surfaces in spatially dense arrangements. Scanning electron microscopy measurements of the separation between nanowires have demonstrated spatial precision of the order of 100 nanometers. By placing semiconductor nanowires on silicon dioxide, they were able to create a multi-wavelength nanolaser system.

“As a manufacturing technique, this printing approach is not limited to optical devices,” Jevtics said. “We hope that electronics specialists will also see application possibilities in future systems.”

In a next step, the researchers are working to replicate these results with a larger number of devices to show that it works on a larger scale. They also wish to combine their transfer printing approach with an automated alignment technique they have previously developed to enable rapid measurement, selection and transfer of hundreds of isolated devices for applications in imaging and circuitry. hybrid optics.

Nanometer scale silicon pattern

Dimitars Jevtics et al, Spatially dense integration of micron scale devices from multiple materials on a single chip via transfer printing, Optical materials Express (2021). DOI: 10.1364 / OME.432751

Provided by the Optical Society

Quote: Researchers Integrate Optical Devices Made of Multiple Materials on One Chip (2021, September 29) Retrieved September 30, 2021 from https://phys.org/news/2021-09-optical-devices-multiple-materials-chip .html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link