[ad_1]

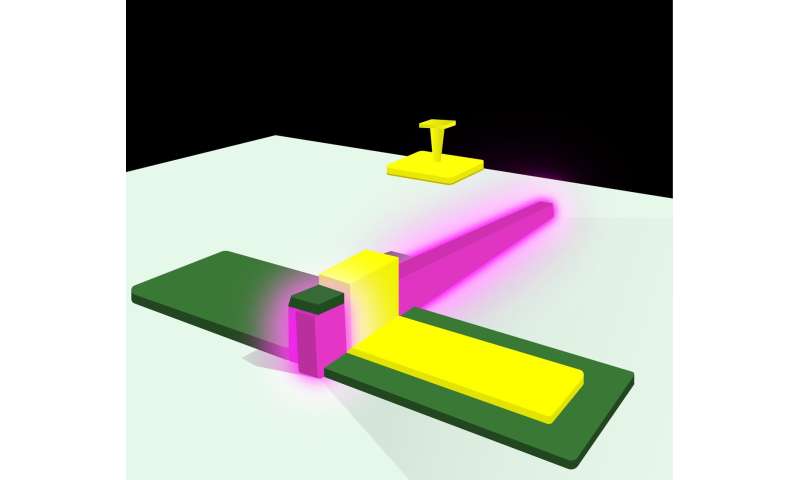

The design of the finned LED pixel includes the glowing zinc oxide fin (purple), the insulating dielectric material (green) and the metallic contact (yellow on top of green). Credit: B. Nikoobakht / N. Hanacek, NIST

A new design for light emitting diodes (LEDs) developed by a team including scientists from the National Institute of Standards and Technology (NIST) may hold the key to overcoming a long-standing limitation in the efficiency of light sources. The concept, demonstrated with microscopic LEDs in the lab, allows for a dramatic increase in brightness as well as the ability to create laser light – all characteristics that could make it useful in a range of large-scale and miniaturized applications.

The team, which also includes scientists from the University of Maryland, the Rensselaer Polytechnic Institute and the IBM Thomas J. Watson Research Center, detailed their work in an article published today in the peer-reviewed journal . Scientific advances. Their device shows an increase in brightness of 100 to 1000 times compared to the tiny conventional LED designs of submicron size.

“This is a new architecture for manufacturing LEDs,” said Babak Nikoobakht of NIST, who designed the new design. “We use the same materials as conventional LEDs. The difference between ours is their shape.”

LEDs have been around for decades, but the development of bright LEDs won a Nobel Prize and ushered in a new era of lighting. However, even modern LEDs have a limitation that frustrates their designers. Up to a point, powering an LED with more electricity makes it glow brighter, but soon the brightness decreases, making the LED very inefficient. Referred to as a “drop in efficiency” by the industry, the problem hinders the use of LEDs in a number of promising applications, from communications technology to virus removal.

Although their new LED design overcomes the drop in efficiency, the researchers did not initially seek to address this problem. Their main goal was to create a microscopic LED for use in very small applications, such as the lab-on-a-chip technology that scientists at NIST and elsewhere are pursuing.

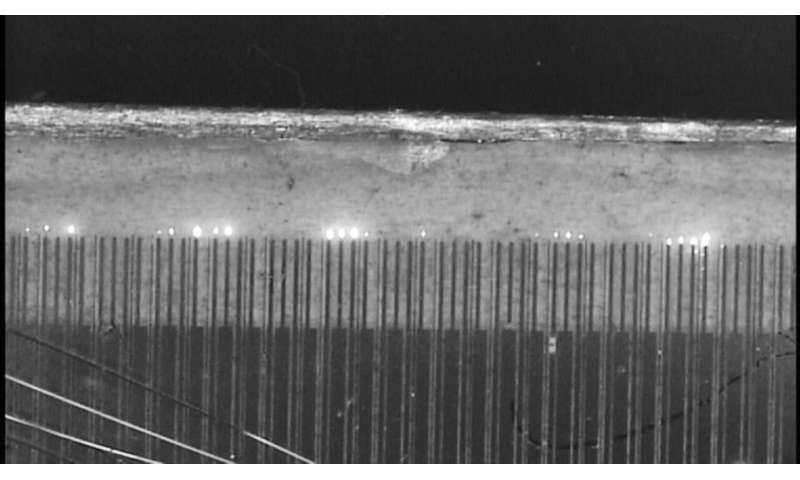

The team experimented with an entirely new design for the part of the LED that glows: unlike the flat, planar design used in conventional LEDs, the researchers constructed a light source from long, thin strands of oxide. zinc which they call fins. (Long and slender are relative terms: each fin is only about 5 microns in length, spanning about a tenth the width of an average human hair.) Their fin array resembles a small comb that can spread to areas as large as 1 centimeter or more.

“We saw an opportunity in the fins, because I thought their elongated shape and large side facets could receive more electric current,” Nikoobakht said. “At first, we just wanted to measure what the new design might take. We started to turn up the current and thought we were going to drive it until it burned out, but it just kept getting brighter.

A comb shaped array of finned LEDs, some of which are bright (light spots at the ends). Credit: B. Nikoobakht / NIST

Their original design shone brilliantly in wavelengths straddling the border between violet and ultraviolet, generating around 100 to 1000 times more energy than typical tiny LEDs. Nikoobakht characterizes the result as an important fundamental discovery.

“A typical LED with an area of less than a square micrometer shines with about 22 nanowatts of power, but this can produce up to 20 microwatts,” he said. “This suggests that the design may overcome the slower efficiency of LEDs to create brighter light sources.”

“This is one of the most effective solutions I’ve seen,” said Grigory Simin, professor of electrical engineering at the University of South Carolina who was not involved in the project. “The community has been working for years to improve the efficiency of LEDs, and other approaches often have technical problems when applied to LEDs of sub-micron wavelength. This approach does the job well.

The team made another surprising discovery by increasing the current. While the LED glowed in a range of wavelengths at first, its relatively wide emission eventually narrowed to two wavelengths of intense purple color. The explanation became clear: their tiny LED had turned into a tiny laser.

“Converting an LED to a laser takes a lot of effort. It usually requires coupling an LED to a resonant cavity which allows the light to bounce back to form a laser,” Nikoobakht said. “It looks like the fin design can do all the work on its own, without needing to add another cavity.”

A small laser would be essential for chip-scale applications, not only for chemical detection, but also in next-generation wearable communications products, high-definition displays, and disinfection.

“He has a lot of potential to be an important component,” Nikoobakht said. “While not the smallest laser that people have made, it is a very bright laser. The lack of drop in efficiency might make it useful.”

Red light LED for new generation screens

“High-luminosity submicrometer laser activated by finned light-emitting diodes (LEDs) without droop” Scientific advances (2020). advances.sciencemag.org/lookup… .1126 / sciadv.aba4346

Provided by the National Institute of Standards and Technology

Quote: Bright, Tiny Light: Scientists Build Better Nanoscale LED (August 14, 2020) Retrieved August 16, 2020 from https://phys.org/news/2020-08-bright-tiny-scientists-nanoscale .html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link