[ad_1]

An illustration of the cage structures of two iron-based zeolites used in the study. The red and gold spheres (representing oxygen and iron respectively) constitute the active site. The cage structure, in gray, is formed from silicon, aluminum and oxygen. The blue sphere quantifies the size of the largest molecule that can freely diffuse in and out of the active site cage (the diameter of methane is approximately 4.2). Credit: Benjamin Snyder

A team of researchers from Stanford University and the University of Louvain in Belgium has elucidated an intriguing process that could be an important step towards methanol fuel economy with abundant methane as a feedstock, a breakthrough that could fundamentally change the way the world uses natural gas.

Methanol, the simplest alcohol, is used to make a variety of products, such as paints and plastics, and as an additive to gasoline. Rich in hydrogen, methanol can power next-generation fuel cells that could provide significant environmental benefits.

If natural gas, of which methane is the main component, could be economically converted to methanol, the resulting liquid fuel would be much easier to store and transport than natural gas and pure hydrogen. It would also significantly reduce methane emissions from natural gas processing plants and pipelines. Today, the escaping methane, a much more potent greenhouse gas than carbon dioxide, almost negates the environmental advantages of natural gas over oil and coal. The team’s new study in the current edition of Science is their latest to come up with a low-energy method to produce methanol from methane.

“This process uses common crystals known as iron zeolites which are known to convert natural gas to methanol at room temperature,” says Benjamin Snyder, who earned his PhD at Stanford studying catalysts to address key aspects of this challenge. “But, this is an extremely difficult chemistry to achieve practically, because methane is stubbornly chemically inert.”

When methane is infused into porous iron zeolites, methanol is rapidly produced at room temperature without the need for additional heat or energy. By comparison, the conventional industrial process of making methanol from methane requires temperatures of 1000 ° C (1832 ° F) and extremely high pressure.

“It is an economically attractive process, but it is not that easy. There are significant obstacles preventing this process from being extended to industrial levels,” said Edward Solomon, professor of chemistry and photon science at Stanford at SLAC. National Accelerator Laboratory. Solomon is the lead author of the new study.

Keep zeolites on

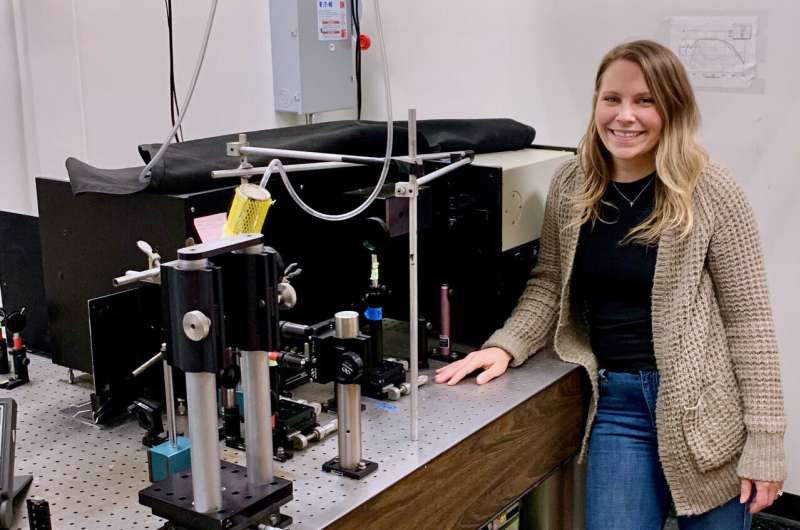

Unfortunately, most iron zeolites deactivate quickly. Unable to process more methane, the process stops. Scientists wanted to study ways to improve the performance of iron zeolite. The new study, co-authored by Hannah Rhoda, a Stanford doctoral student in inorganic chemistry, uses advanced spectroscopy to explore the physical structure of the most promising zeolites for the production of methane to methanol.

Hannah Rhoda with resonance Raman spectroscopy equipment, which shoots a laser into a sample to obtain vibrational information from the exact site studied. The researchers in the present study used this technique to help assign the poisoned Fe (III) -OH and Fe (III) OCH3 sites, which shed light on the mechanism. Credit: Hannah Rhoda

“A key question here is how to extract the methanol without destroying the catalyst,” said Rhoda.

By choosing two attractive iron zeolites, the team studied the physical structure of the networks around the iron. They found that the reactivity varies greatly depending on the pore size of the surrounding crystal structure. The team calls it the “cage effect” because the encapsulation network looks like a cage.

If the pores of the cages are too large, the active site will deactivate after a single reaction cycle and never reactivate again. However, when the pore openings are smaller, they coordinate a precise molecular dance between the reactants and the active sites of iron, a dance that directly produces methanol and regenerates the active site. By taking advantage of what is known as the “cage effect”, the team was able to reactivate 40% of deactivated sites multiple times, a significant conceptual advance towards an industrial-scale catalytic process.

“Catalytic cycling – the continuous reactivation of regenerated sites – could one day lead to continued and economical production of methanol from natural gas,” said Snyder, now a postdoctoral fellow at UC-Berkeley in the chemistry department under the leadership by Jeffrey R. Long.

Benjamin Snyder (right) and his former thesis supervisor Edward Solomon, professor of chemistry at Stanford and photon science at SLAC. Credit: Linda A. Cicéron

This fundamental step forward in basic science will help to elucidate for chemists and chemical engineers the process used by iron zeolites to produce methanol at room temperature, but much work remains to be done before such a process can be implemented. industrialized.

Next on Snyder’s list: tackle carrying out the process not only at room temperature, but using ambient air rather than another source of oxygen, such as the nitrous oxide used in these experiments. Dealing with a strong oxidizing agent like oxygen, which is notoriously difficult to control in chemical reactions, will be another considerable hurdle along the way.

For now, Snyder was both satisfied and amazed by the illustrative powers of the sophisticated spectroscopic instrumentation from Solomon’s laboratories that were harnessed for this study. These were invaluable to his understanding of the chemistry and chemical structures involved in the process of transforming methane into methanol.

“It’s great that we can get very powerful information at the atomic level, like the cage effect, from these tools that weren’t available to previous generations of chemists,” Snyder said.

New method converts methane in natural gas to methanol at room temperature

Benjamin ER Snyder et al, Cage effects control the mechanism of methane hydroxylation in zeolites, Science (2021). DOI: 10.1126 / science.abd5803

Provided by Stanford University

Quote: Scientists convert methane to methanol at room temperature (2021, July 16) retrieved July 16, 2021 from https://phys.org/news/2021-07-scientists-methane-methanol-room-temperature.html

This document is subject to copyright. Other than fair use for private study or research purposes, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link