[ad_1]

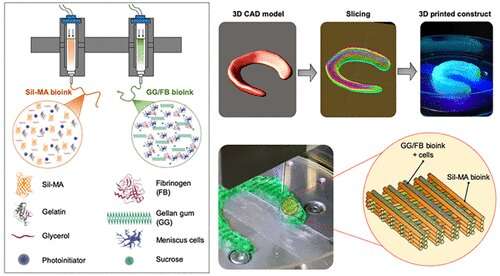

A highly elastic hybrid construct for fibrocartilaginous regeneration is produced by copinting a cell-loaded gellan gum / fibrinogen composite bioinque with a silk fibroin methacrylate bioinque in an interwoven hatch pattern. Credit: WFIRM

Scientists at the Wake Forest Institute for Regenerative Medicine (WFIRM) have developed a method to bioprint a type of cartilage that could one day help restore function to the knee damaged by arthritis or injury.

This cartilage, known as fibrocartilage, helps connect tendons or ligaments or bones and is mainly found in the meniscus of the knee. The meniscus is the hard, rubbery cartilage that acts as a shock absorber in the knee joint. Meniscus tissue degeneration affects millions of patients, and arthroscopic partial meniscectomy is one of the most common orthopedic operations. Besides surgery, the available treatment options are lacking.

In this latest proof of concept strategy, scientists were able to 3-D print a hybrid tissue construct for cartilage regeneration by printing two specialized bioinks – hydrogels containing the cells – together to create a new formulation that supplies a cell. friendly micro-environment and structural integrity. This work is done with the Integrated Tissue and Organ Printing System, a 3D bioprinter that has been developed by researchers at WFIRM over a period of 14 years. The system deposits both biodegradable plastic-like materials to form the “shape” of tissues and bioinks that contain cells to build new tissues and organs.

“In this study, we were able to produce a highly elastic hybrid construct for advanced fibrocartilaginous regeneration,” said Sang Jin Lee, Ph.D, associate professor at WFIRM and author of the recently published article by Materials chemistry newspaper. “The results demonstrate that this bio-printed construct offers a versatile and promising alternative for the production of this type of fabric.”

For the study, Lee and the WFIRM research team tested various formulations and measured the response to applied forces or stresses, the swelling rate, and the strength and flexibility of the material. One provided the appropriate cellular microenvironment to maintain cells and help them grow while the other bioink provided excellent biomechanical behavior and structural integrity. The final formula of the two bioinks used was co-printed layer by layer to create a mesh-like pattern. Constructs were implanted in a small animal model for observation for 10 weeks and evaluated at intermittent time periods, showing appropriate function.

“A larger preclinical study will be needed to further examine the body’s response and functional recovery of the joint with the use of this regenerative medicine treatment,” said James Yoo, MD, Ph.D., professor at WFIRM.

“We have such a need for effective treatments and therapies to help patients cope with degenerative joint problems, especially in the knee,” said Anthony Atala, MD, director of WFIRM. “This proof of concept study helps us point our work in the right direction to one day be able to design this crucial tissue that is so important to patients.”

Neural cells accelerate the function of 3D bio-printed skeletal muscle constructions

João B. Costa et al, 3D bio-printed highly elastic hybrid constructs for advanced regeneration of fibrocartilaginous tissues, Materials chemistry (2020). DOI: 10.1021 / acs.chemmater.0c03556

Provided by Wake Forest University Baptist Medical Center

Quote: Scientists Create Hybrid Tissue Construct For Cartilage Regeneration (2020, November 9) Retrieved November 9, 2020 from https://phys.org/news/2020-11-scientists-hybrid-tissue-cartilage-regeneration.html

This document is subject to copyright. Other than fair use for study or private research, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link