[ad_1]

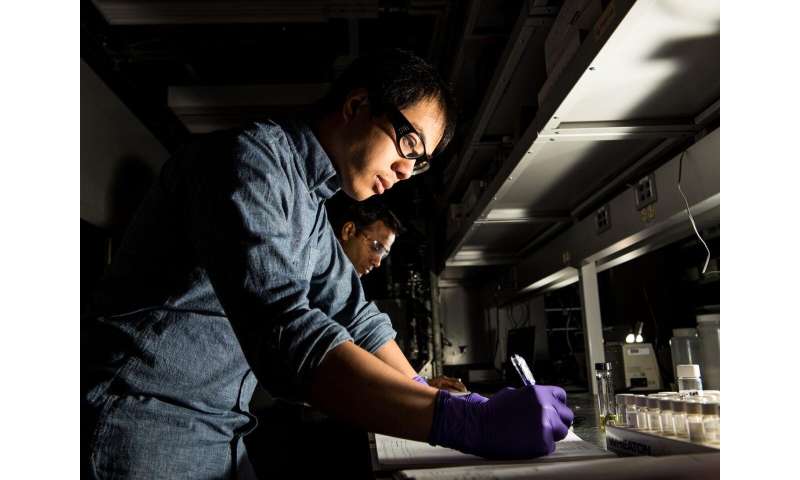

Scientists at the Pacific Northwest National Laboratory have developed a new catalyst that converts ethanol into C5 + ketones that can serve as the building blocks for everything from solvents to jet fuel. In a new article, they describe this revolutionary chemistry and the mechanism behind it. Credit: Andrea Starr | Pacific Northwest National Laboratory

While we generally think of ethanol as the fuel for the gas tank, it can also be turned into valuable chemicals that could help replace a variety of petroleum products beyond gasoline. However, the evolution of ethanol for a wider range of industries requires more efficient chemical processes than what is available today.

Scientists at the Pacific Northwest National Laboratory (PNNL) have developed a new catalyst that converts ethanol into C5 + ketones that can serve as the building blocks for everything from solvents to jet fuel. In a new article, they describe this revolutionary chemistry and the mechanism behind it.

One-pot ethanol upgrade to C5 + ketones

Catalysts are needed to speed up the chemical transformations that convert ethanol into other compounds. To be commercially viable, a catalyst must be highly active while selectively generating the desired chemicals – in other words, it must reliably produce the exact material desired. Scientists are looking for catalysts for ethanol that can efficiently produce the right compounds and do so repeatedly. In chemistries that require many reaction steps in a long cascade of chemical reactions to the final end product, this can be a daunting task.

The catalyst developed at PNNL condenses several reactions in a single step. Ethanol meets the catalyst under high temperature (370 ° C or 698 ° F) and pressure (300 pounds per square inch). It then transforms quickly into products containing over 70% C5 + ketones. The catalyst also appears robust, remaining stable over 2000 hours of use. The end goal is to have a catalyst that can last from 2 to 5 years.

For their research, the scientists combined zinc oxide and zirconium dioxide for the catalyst. Such mixed oxide catalysts generally do not achieve such selectivity, instead resulting in too many unwanted by-products.

But the researchers added another key ingredient to the mix: palladium. In the process, palladium and zinc formed an alloy that behaves very differently from its components, catalyzing only the necessary reaction steps that lead to the formation of C5 + ketones.

“What’s new is to produce these ketones by forming the alloy between palladium and zinc during the reaction,” said Karthi Ramasamy, study co-author and senior research engineer at PNNL. “So many intermediate steps all occur on this one catalyst – each step requires a different component of the catalyst to activate it.”

One catalyst, flexible operation

The catalyst can be used to make 2-pentanone and / or 2-heptanone, which are used in solvents for the electronics industry and are generally derived from petroleum. C5 + ketones can also act as intermediates to produce a mixture of fuel, lubricants, jet fuel and diesel fuel. Producing these products from renewable ethanol rather than fossil fuels could help reduce greenhouse gas emissions and enhance energy security.

“This catalyst is very flexible,” Ramasamy said. “We can make adjustments to operating conditions, such as temperature and pressure, to achieve the desired product composition.”

The process is detailed in more detail in the article “Direct catalytic conversion of ethanol to C5 + ketones: role of the Pd-Zn alloy on catalytic activity and stability”, published in the journal Angewandte Chemie International Edition.

Laboratory steps on gas to improve chemical production

Senthil Subramaniam et al. Direct catalytic conversion of ethanol into C 5+ ketones: role of the Pd – Zn alloy on catalytic activity and stability, Angewandte Chemie International Edition (2020). DOI: 10.1002 / anie.202005256

Provided by Pacific Northwest National Laboratory

Quote: Scientists Develop Catalyst to Convert Ethanol into High-Value Chemicals and Fuels (Nov 10, 2020) Retrieved Nov 10, 2020 from https://phys.org/news/2020-11-scientists-catalyst-ethanol- high-value-chemicals .html

This document is subject to copyright. Apart from any fair use for study or private research, no part may be reproduced without written permission. The content is provided for information only.

[ad_2]

Source link