[ad_1]

Elon Musk, CEO of SpaceX, has suggested that the new Starship and Super Heavy rocket (previously known as BFR) could make its first integrated launches – putting Starship in orbit – in the next 12 to 24 months starting today. 'hui.

Musk said the chances of the spacecraft reaching orbit by 2020 are now "60% [and] is increasing rapidly, "largely thanks to the many radical changes that the spacecraft and its amplifier have undergone in 2018.

60% probability and rapid increase due to new architecture

– Elon Musk (@elonmusk) December 27, 2018

Combined with a decision – made public during a media event in September 2018 – to delay the launch of a vacuum-optimized upper-floor Raptor (RVac) and stick to its variant Mature sea level, Musk is apparently confident that these dramatic changes in strategy will allow SpaceX to aggressively reduce the development schedules of its next-generation launcher. Surprisingly, Musk noted that while these "radical" design changes are almost entirely motivated by his desire to speed up the operational launch of the fully reusable rocket, it has become apparent that the cheaper iteration In fact, faster and easier could actually be (in Musk's own words) "considerably better" than his composite exotic carbon composite ancestor.

Time. Although it turned out to be much better.

– Elon Musk (@elonmusk) December 27, 2018

"Deliciously counterintuitive"

Leave a doubt, I'm still extremely skeptical about this radical overhaul and the incredible logistics of doing this last-minute redesign while maintaining the test program, let alone speeding it up from 6 to 9 months. Although Musk seems to have a convincing rational answer to all the questions posed so far, he was no less convincing in mid-2016 when he had declared with contagious conviction that the ## 147 ## Tesla's Fremont factory would be an "alien dreadnought almost 100% automated" By 2018. There is of course nothing wrong in itself To be wrong, even if it takes 24 months and several hundred million dollars to achieve the same, can be downright fatal or at least represent a major health risk for any company faced with such a challenge, as was the case with Tesla.

With skepticism aside, there are also many reasons to be optimistic about the future of SpaceX's SpaceX / Super Heavy (BFR) program over the next few years. Not only were the hot metal structures proven (in the 1960s and in the suborbital conditions, but still), but the century and a half that men built and built with steel aggressively to reduce the risks associated with the development of BFR, while a giant, highly reusable spacecraft and rocket, built mainly of carbon composites, is as exotic, stimulating and as strange as possible. A little further, Musk seems to be convinced that the benefits of moving from composite stainless steel to stainless steel far away outweigh the costs.

BFS / Starship shows part of its thermal shield. SpaceX may be looking for an advanced NASA solution for the BFR thermal protection system. (SpaceX)

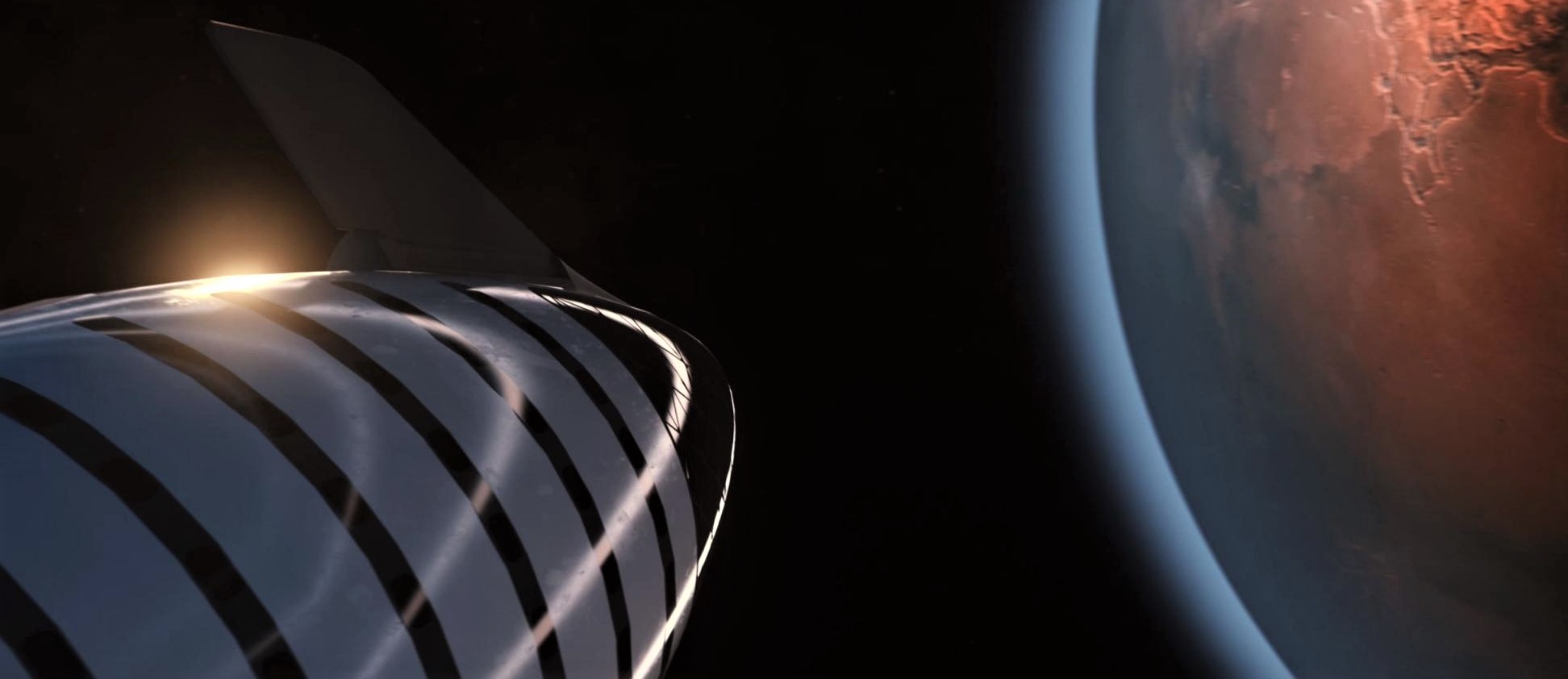

BFR – in its design iteration 2018 – is seen penetrating at high speed in the atmosphere of Mars. (SpaceX)

Starship – in its 2018 design iteration – seen landing on Mars at the top of the Raptor Flame Pillars. (SpaceX)

Elon Musk, CEO of SpaceX, has visited the South Texas site where the first prototype of Starship is under construction on December 23rd. (Elon Musk)

Starship … or BFWTF? (NASASpaceflight / u / bocachicagal)

In particular, Musk thought that a steel-alloy skin – even with regenerative (liquid) cooling – could truly replace SpaceX's PICA-X ablative heat shield technology on Starship was the least intuitive but logical change. . Although steel alloys can Literally With densities well above those of carbon composites, composites simply can not (at least in the current state of the art) withstand temperatures as high as those that Starship would inevitably experience during orbital and interplanetary returns. As a result, Starship would require an extremely advanced, minimal ablative, extremely lightweight, robust and shock-resistant thermal shield technology, not to mention an additional layer capable of mounting it on Starship's composite shell while isolating the tanks. and the thruster structure of the extreme heat of re-entry.

The lee side does not need anything, the windward side will have a cooled activity with residual liquid methane (cryo), so the cash will appear even on the warm side

– Elon Musk (@elonmusk) December 25, 2018

Steel, meanwhile, is one of the least thermally conductive metals on the market, while having alloys whose melting point can reach and even exceed 1500 ° C. With the regenerative cooling, it is all about possible that a hot steel armor and fusion propeller tanks and load-bearing structures could ultimately give a spacecraft much more reusable, reliable and perhaps even more efficient than a spaceship based on shield materials Exotic thermal and propellant tanks made of unlined carbon composite.

Perhaps blocks 2 or 3 of BFRs will give way to significantly improved composite formulations and production methods, but advanced steels and other metal alloys seem to be the way forward for SpaceX at the moment. At the moment, we can sit, watch and wait Something meets at the company's test and launch facilities in South Texas.

For quick updates, on-the-ground perspectives and unique insights from the SpaceX rocket recovery fleet, check out our latest LaunchPad and LandingZone newsletters!

[ad_2]

Source link