[ad_1]

Researchers from Lawrence Berkeley National Laboratory, an office laboratory of the Department of Energy (DOE) managed by University of California, to have Printed in 3D, an all-liquid device for the chemical synthesis of batteries and drug formulations.

"Our 3D printed device can be programmed to perform complex, multi-step, on-demand chemical reactions," said Brett Helms, a researcher at Berkeley Lab, responsible for materials science, and Molecular Foundry, who led the company. 39, a study published in Nature Communications.

"What's even more amazing is that this versatile platform can be reconfigured to efficiently and accurately combine molecules to form very specific products, such as organic battery materials."

All liquid 3D prints

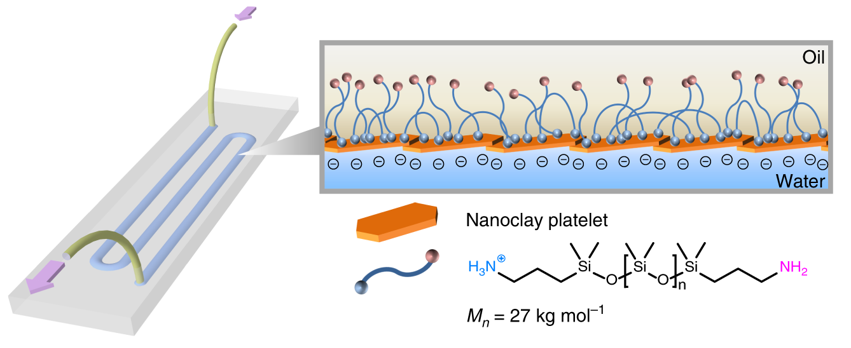

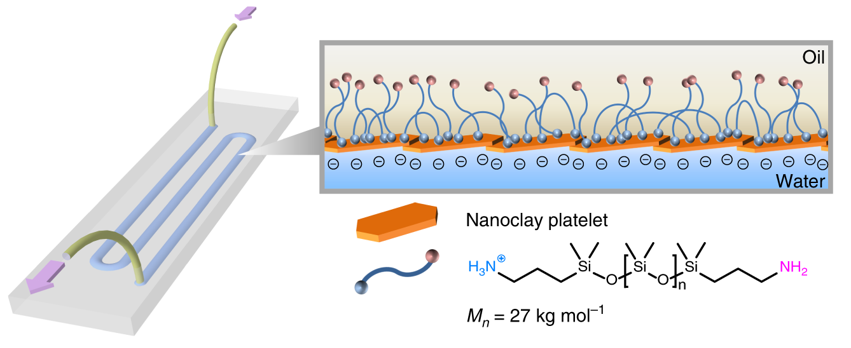

Last year, Helms and Thomas Russell, a visiting scientist in the Materials Science division of Berkeley Lab, developed new liquid structures using a modified Qidi X-one 3D printer. With the X-one, liquids were printed in microns, allowing researchers to "place nets of water wherever we wanted in three dimensions".

These water nets have created liquid tube structures suspended in an oil container. This research led the Berkely Lab team to further their research on the applications of this method. Helms added, "After this successful demonstration, many of us got together to think about how we could use liquid printing to make a functional device."

"Then we thought, if we could print liquids in defined channels and circulate the contents without destroying them, then we could make fluidic devices useful for a wide range of applications, new types of chemical laboratories. miniaturized batteries and electronic devices. . "

3D printable fluidic devices

To create a 3D printable fluidic device, Wenqian Feng, a postdoctoral researcher in the Materials Science division of Berkeley Lab and lead author of the new study, designed a special patterned glass substrate.

This allows two liquids to join in a few milliseconds to form a very thin channel or tube of about 1 millimeter in diameter. These liquids consist of nanometer-sized clay particles and polymer particles and can be 3D printed as bridges between channels to connect flowing chemicals. With computer controls, a desired chemical reaction can be performed.

Helms continued, "The form and function of these devices are limited only by the imagination of the researcher."

"Autonomous synthesis is a new area of interest in the chemistry and materials communities, and our technique for 3D printing devices for all-liquid flow chemistry could help play an important role in establishing the field."

"Exploiting Liquid-in-Liquid Printing and Microtroned Substrates for the Manufacture of Fully Liquid Three-Dide Fluid Devices", is co-authored by Wenqian Feng, Yu Chai, Joe Forth, Paul D. Ashby, Thomas P. Russell and Brett A. Helms.

Vote for an Academic / Research Team" for the 2019 3D Printing Industry Awards.

Subscribe to our 3D Printing Bulletin and follow us Facebook and Twitter for the latest additive manufacturing updates.

Visit our 3D printing works advice to learn more about the possibilities offered by additive manufacturing.

The presented image shows a fluidic device all liquid printed in 3D. Clip via the Lawrence Berkeley National Laboratory.

[ad_2]

Source link