[ad_1]

(Nanowerk News) Many metals and alloys would be ideal for nanoscale-specific applications – from solar to microelectronics – but the precise molding of metals in such tiny shapes has proven difficult. Researchers have, however, developed a process that allows manufacturers to shape essentially all metals and alloys and to reproduce the smallest details.

Laboratories of Jan Schroers, Professor of Mechanical Engineering and Materials Science at Yale, and Professor Ze Liu of Wuhan University in China have developed a method, called thermomechanical nanomoulding, which allows them to to mold crystalline metals into shapes up to a few nanometers in diameter.

According to the researchers, this breakthrough could lead to new technologies in areas such as sensors, batteries, catalysis, biomaterials and quantum materials.

The results are published in Letters of physical examination ("Nanomolding of crystalline metals: the smallest is the easiest").

"It's really a new way of nanofabrication," said Schroers. "Today's nanofabrication relies on a few materials that can be made very specifically for a particular material. But our discovery suggests a technique for all metals and alloys: it allows us to essentially make all metals and their combination in the periodic table predictably and accurately to nanoscale characteristics. "

The molding of crystalline metals, which include most metals in the solid state, has generally posed a challenge to manufacturers, the researchers said. The moldability of a material usually depends on its "fluidity", ie its ease of flow under certain conditions. Fluidity is high in thermoplastics, gels and glasses, but most metals are too hard when they are solid and too liquid in the liquid state to mold themselves with conventional techniques. nanoscale.

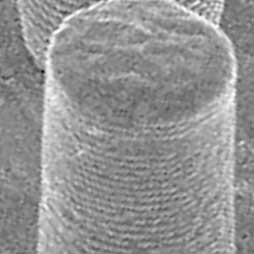

But by applying atomic scattering, in which a change of pressure transports the atoms, the research team discovered that they could not only effectively mold crystalline metals, but that by reducing the size of the mold, the process was more easy. As a result, they could create very long features of a diameter of about 10 nanometers, 8,000 times smaller than a human hair, that it would have been impossible to create before.

Because the diffusion mechanism is present in all metals and alloys, the process could theoretically be used in all fields, the researchers said. To test the wide range of applications, researchers have tried to mold gold, nickel, vanadium, iron and many alloys. In each case, they could easily make very small nanorods.

Source link