[ad_1]

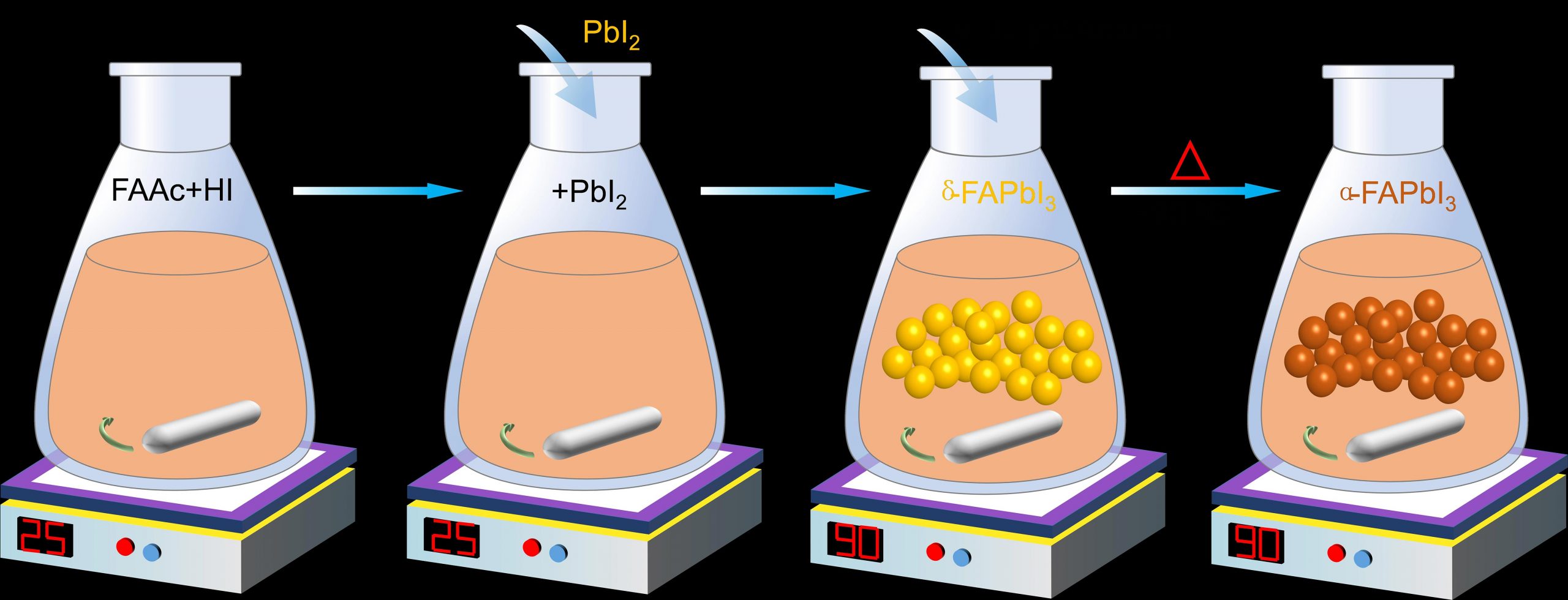

The researchers used a powder engineering method to create a high-quality version of FAPbI3. First, they mixed formamidinium acetate (FAAc) with hydriodic acid (HI). PbI2 was then added. The mixture was then heated to 90 degrees Celsius. In the final step, any remaining impurities or unreacted materials were dissolved in water and filtered. Credit: OIST

Solar cells, which convert sunlight into electricity, have long been part of the global vision for renewable energy. Although individual cells are very small, when converted into modules, they can be used to charge batteries and power lights. Placed side by side, they could one day be the main source of energy for buildings. But solar cells currently on the market use silicon, making them expensive to manufacture compared to more traditional energy sources.

This is where another material, relatively new to science, comes in, metal halide perovskite. Nestled in the center of a solar cell, this crystal structure also converts light into electricity, but at a much lower cost than silicon. Additionally, perovskite-based solar cells can be fabricated using rigid and flexible substrates. So, in addition to being cheaper, they could be lighter and more flexible. But, to have real potential, these prototypes must increase in size, efficiency and lifespan.

Now, in a new study, published in Nano energy, researchers from the Energetic Materials and Surface Sciences Unit, headed by Professor Yabing Qi, of the Okinawa Institute of Science and Technology Graduate University (OIST) have demonstrated that the creation of one of the raw materials necessary for perovskites d ‘a different way could be the key to the success of these cells.

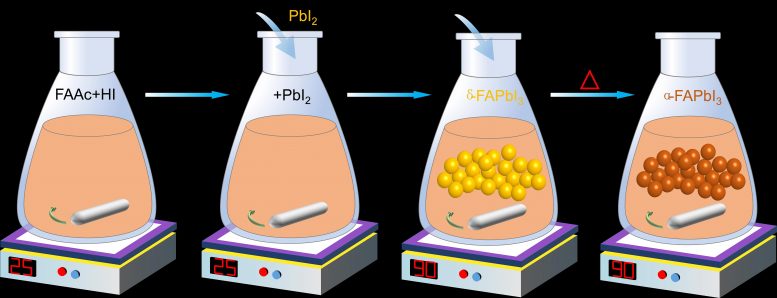

A proof of concept device created by the OIST Energy Materials and Surface Sciences unit uses a perovskite solar module to charge a lithium-ion battery. Credit: OIST

“There is a necessary crystalline powder in perovskites called FAPbI3, which forms the absorbent layer of perovskite,” explained one of the lead authors, Dr Guoqing Tong, postdoctoral researcher in the unit. “Previously, this layer was made by combining two materials – PbI2 and FAI. The reaction which takes place produces FAPbI3. But this method is far from perfect. There are often remnants of one or both of the original materials, which can affect the efficiency of the solar cell.

To get around this problem, the researchers synthesized the crystalline powder using a more precise powder engineering method. They still used one of the raw materials – PbI2 – but also included additional steps, which involved, among other things, heating the mixture to 90 degrees Celsius and carefully dissolving and filtering the leftovers. This ensured that the resulting powder was of high quality and structurally perfect.

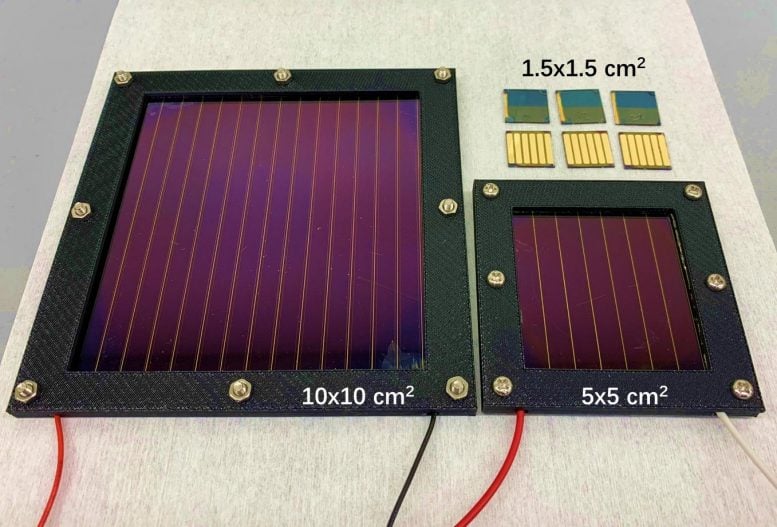

OIST’s Energetic Materials and Surface Sciences Unit works with perovskite solar cells and modules of various sizes. Credit: OIST

Another advantage of this method was that the stability of the perovskite increased at different temperatures. When the absorbent layer of perovskite formed from the original reaction, it was stable at high temperature. However, at room temperature it turned from brown to yellow, which was not ideal for absorbing light. The synthesized version was brown even at room temperature.

In the past, researchers created a perovskite-based solar cell with an efficiency of over 25%, which is comparable to silicon-based solar cells. But, to move these new solar cells beyond the lab, high-end size and long-term stability are needed.

“Laboratory-scale solar cells are tiny,” said Professor Qi. “The size of each cell is only about 0.1cm2. Most researchers focus on the latter because they are easier to create. But, in terms of applications, we need solar modules, which are much bigger. The lifespan of solar cells is also an element that we must take into account. Although an efficiency of 25% had been achieved previously, the service life was, at most, a few thousand hours. After that, the efficiency of the cell began to decline.

Using the synthesized crystalline perovskite powder, Dr. Tong, alongside postdoctoral fellow Dr. Dae-Yong Son and other scientists in Prof. Qi’s unit, achieved a conversion efficiency of over 23% in their solar cell. , but the service life was over 2000 hours. When they switched to 5×5 cm2 solar modules, they still achieved an efficiency of over 14%. As a proof of concept, they made a device that used a perovskite solar module to charge a lithium-ion battery.

These results represent a crucial step towards efficient and stable perovskite-based solar cells and modules that could one day be used outside the laboratory. “Our next step is to make a 15 x 15 cm solar module2 and has an efficiency of over 15%, ”said Dr Tong. “One day, I hope we can power an OIST building with our solar modules. “

This work was supported by the proof of concept program of the Technology Development and Innovation Center of OIST.

Reference: “Removal of residual compositions by powder engineering for high efficiency formamidinium-based perovskite solar cells with lifespan of over 2000h” by Guoqing Tong, Dae-Yong Son, Luis K. Ono, Hyung- Been Kang, Sisi He, Longbin Qiu, Hui Zhang, Yuqiang Liu, Jeremy Hieulle and Yabing Qi, May 13, 2021, Nano energy.

DOI: 10.1016 / j.nanoen.2021.106152

[ad_2]

Source link