[ad_1]

The MIT Media Lab at MIT (Massachusetts Institute of Technology) is renowned for applying 3D printing to some of the most unusual and inspired projects.

Neri Oxman, artist, architect, glass 3D printer and Stratasys partner, leads the Mediated Matter group of the lab. And Neil Gershenfeld, director of the laboratory's Center for Bits and Atoms, founded Fab Labs. Tangible Media Group is another example of the expertise that is often missing from the lab. Led by Professor Hiroshi Ishii, professor of media arts and sciences at MIT Jerome B. Wiesner, Tangible Media seeks to "seamlessly couple the dual world of bits and atoms by giving a dynamic physical form to the Numerical and numerical information ". seeks to make digital data physically interactive.

Cillliais just one example of Tangible Media Group's groundbreaking work on 3D printing. As its name indicates, this project is an extension of the structure and function of the hair.

Pixel by pixel

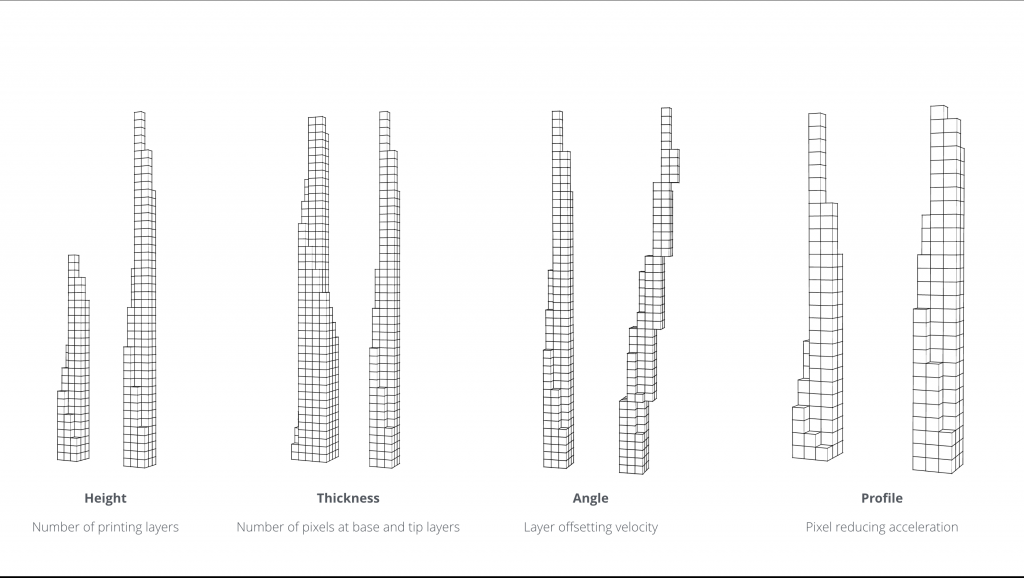

In Cilllia Tangible Media Group scientists have developed pixel-based hair geometry. Not only does this design make the models printable in 3D, but it also makes it easy to modify each strand by adding more pixels to change the height, thickness, angle, and profile.

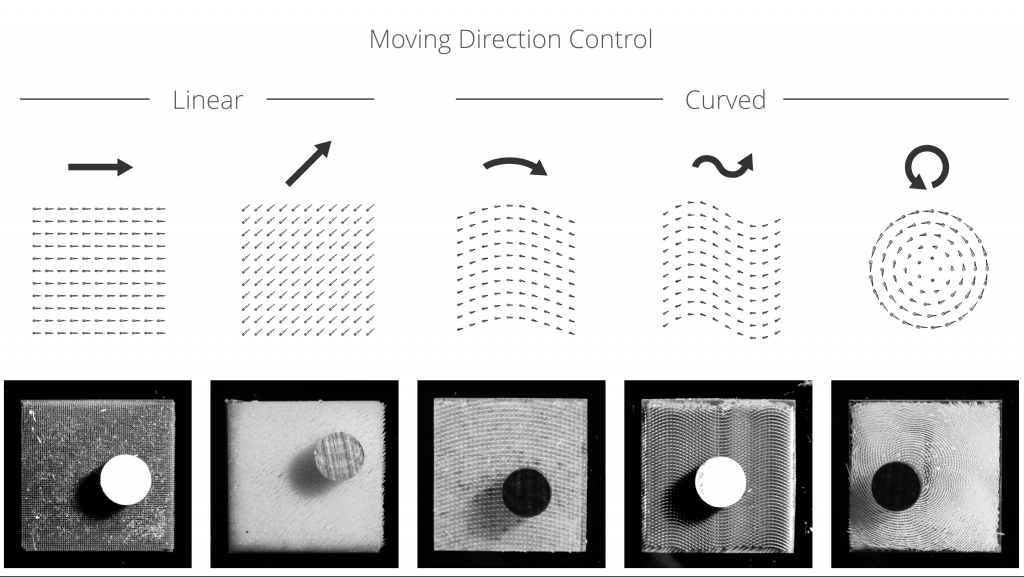

In addition to modifying the artificial hair printed in 3D by the pixel, Cilllia also experiences with their arrangement. As illustrated in the diagram below, the group used linear horizontal, diagonal linear, curved arc, curved wave and curved circular arrays of 3D printed bristles, each corresponding to a different potential motion.

Why hair printed in 3D?

More than just a survey of the printable forms SLA-3D, Cilllia applies these varied parameters to develop a range of possible applications for structures. In one case, 3D printed bristles are used to generate phone vibrations and convert them to wind turbine rotation. In other, Cilllia At the base of the ballerinas, figurines are used to make them "dance" when the music is played.

It also turns out that artificial hair can make an excellent adhesive, and switches. With a hairy surface, the team creates a type of acoustic sensor that, when connected to the piezo microphone, can be used to turn on a light. The researchers explain this particular application in these terms: "One of the most important characteristics of hair in nature is the extent to which they help detect changes in environmental conditions. Many animals, such as caterpillars, use hair on the skin to detect airborne disturbances. "

"In the world of engineering, researchers have learned from the structure of hair to build artificial flow sensors. The construction of these sensors generally requires expensive microfabrication machines and processes. We use the ability to control hair geometry Cilllia combined with an acoustic detection method to quickly produce sensors that detect the direction and speed of human scanning. "

Cilllia – 3D printed hair structures for surface texture, activation and detection of Tangible Media Group on Vimeo.

Further reading

An article describing the project Cilllia was published in the Proceedings of the 2016 CHI Conference and is co-written by Jifei Ou, Gershon Dublon, Cheng Chin-Yi, Felix Heibeck, Karl Willis and Hiroshi Ishii.

Other work in the group includes Materiable project, in which actuators and sensors are applied to a block of pixels printed in 3D. When these pixels are touched, they react and wave like water and correspond to a projection of light. Since then, Ishii and his colleagues Daniel Leithinger, David Lakatos, Anthony DeVincenzi and Matthew Blackshaw have been granted a patent for this method and this device. Recently, Ishii also oversaw a project to create a bacteria-activated cooling suit for runners.

Or and Willis, others Cilllia co-authors, have patented a method of design of 3D printed auxetic structures, awarded to the award-winning Autodesk 3D software company.

Georgia Tech's 3D printed languages are another project to improve the capabilities of hair-like structures. What purpose? To untangle the fur of course.

To learn more about the latest research in 3D printing, subscribe to our newsletter on 3D printing. You can also join us on Facebook and Twitter. Looking for a job in the industry? Visit our table of 3D print jobs.

The selected image shows Cilllia 3D printed. Image via Tangible Media Group / MIT

[ad_2]

Source link