[ad_1]

Researchers at ETH Zurich and Empa chemically modified the wood and made it more compressible, turning it into a mini-generator. When compressed, it generates an electrical voltage. This wood could serve as a biosensor or as a building material that harvests energy.

Ingo Burgert and his team at ETH Zurich Public Research University and the Swiss Federal Laboratory Empa have proven that wood is more than just a building material. Their research enhances the properties of wood in order to use it for new applications. For example, they have already developed high strength, water repellent and magnetizable wood.

Now, in collaboration with the Empa research group led by Francis Schwarze, the team has used a chemical process and a biological process to generate an electrical voltage from a type of wooden sponge. In doing so, they amplify what is called the “piezoelectric effect” of wood.

Compression creates tension

When a piezoelectric material is elastically deformed, it generates an electrical voltage. Measurement technology, in particular, exploits this phenomenon by using sensors that generate a load signal when mechanically stressed. However, many materials often used for these sensors are not suitable for biomedical applications. Lead zirconate titanate (PZT), for example, cannot be used on the skin due to its toxic lead and must be specially removed.

Wood also has a natural piezoelectric effect but generates only a very low electrical voltage. If the tension is to be increased, the chemical composition of the wood must be changed – and this also makes it more compressible.

From block of wood to sponge

In order to convert wood into an easily formable material, a component of the cell walls must be dissolved. The cell walls of wood are made up of three basic substances: lignin, hemicellulose and cellulose. “Lignin is the stabilizing substance that trees need to grow. Without lignin, which binds cells together and prevents rigid cellulose fibrils from deforming, this would not be possible, ”says Burgert.

A few months ago, Jianguo Sun, a doctoral student in Burgert’s team, with colleagues from ETH and Empa, published a study in ACS Nano this explained how wood could be deformable if the lignin was removed chemically. As a result, its piezoelectric effect is improved.

The researchers achieved this “delignification” by placing the wood in a mixture of hydrogen peroxide and acetic acid. The acid dissolves the lignin, leaving a framework of layers of cellulose. “The process maintains the hierarchical structure of the wood and prevents the disassembly of individual fibers,” says Burgert.

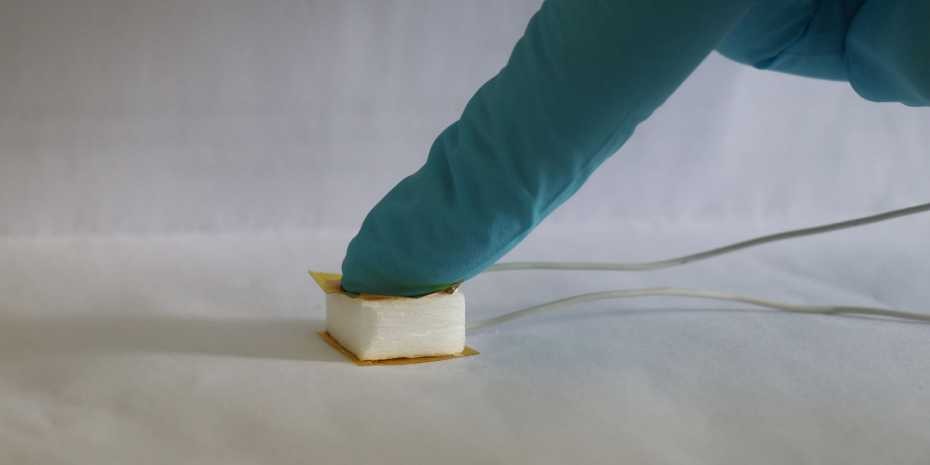

In this way, a piece of balsa wood becomes a white wooden sponge, made up of layer after layer of thin cellulose. The sponge can simply be squeezed and then reverts to its original shape. “The wooden sponge generates an electrical voltage 85 times greater than that of the native [untreated] wood, ”Sun says.

A mini generator in the wooden floor

The team subjected a test cube with a side length of about 1.5 cm to about 600 charge cycles. The wooden sponge was found to be surprisingly stable: for each charge, the researchers measured a voltage of around 0.63 volts, which would be appropriate for a sensor. In other experiments, the team tested the scalability of this mini-generator. If 30 of these wooden blocks are connected and charged evenly with an adult’s body weight, enough electricity is generated to power a simple LCD display.

Treatment with fungi instead of chemicals

In a follow-up study just published in Scientific progress, the ETH-Empa research team went further by seeking to produce the wooden sponge without using chemicals. Researchers found the solution in nature: the fungus Ganoderma applanatum causes white rot in wood and gently degrades lignin and hemicellulose. “Although the electrical voltage generated was lower in the initial tests than with chemically treated wood, the fungal process is more environmentally friendly,” says Burgert.

Such a simple renewable piezoelectric system has obvious advantages. Researchers see various potential applications for wooden sponges – for example, as durable building materials that harvest energy during the use phase or as skin-friendly pressure sensors for medical purposes.

However, there are still several steps to be taken before piezoelectric wood can be deployed as a biosensor, or even as an electricity recuperating parquet. Burgert and his colleagues are now exploring with various partners how to adapt the technology to industrial applications.

News source: ETH Zurich editorial team

Main photo: Joel & Jasmin Førestbird / Unsplash

FTC: We use automatic income generating affiliate links. After.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

[ad_2]

Source link